Website:

Curtis Universal

Website:

Curtis Universal

Catalog excerpts

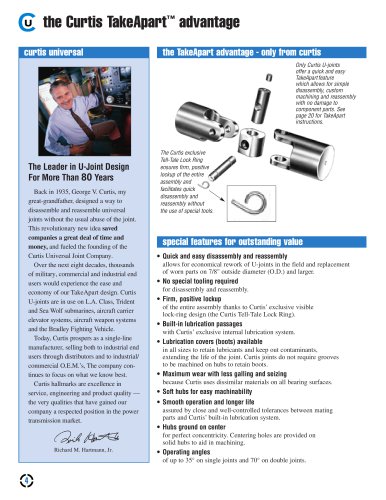

curtis universal the TakeApart advantage - only from curtis The Leader in U-Joint Design For More Than 80 Years Back in 1935, George V. Curtis, my great-grandfather, designed a way to disassemble and reassemble universal joints without the usual abuse of the joint. This revolutionary new idea saved companies a great deal of time and money, and fueled the founding of the Curtis Universal Joint Company. Over the next eight decades, thousands of military, commercial and industrial end users would experience the ease and economy of our TakeApart design. Curtis U-joints are in use on L.A. Class, Trident and Sea Wolf submarines, aircraft carrier elevator systems, aircraft weapon systems and the Bradley Fighting Vehicle. Today, Curtis prospers as a single-line manufacturer, selling both to industrial end users through distributors and to industrial/ commercial O.E.M.’s, The company continues to focus on what we know best. Curtis hallmarks are excellence in service, engineering and product quality — the very qualities that have gained our company a respected position in the power transmission market. Only Curtis U-joints offer a quick and easy TakeApart feature which allows for simple disassembly, custom machining and reassembly with no damage to component parts. See page 20 for TakeApart instructions. The Curtis exclusive Tell-Tale Lock Ring ensures firm, positive lockup of the entire assembly and facilitates quick disassembly and reassembly without the use of special tools. special features for outstanding value • Quick and easy disassembly and reassembly allows for economical rework of U-joints in the field and replacement of worn parts on 7/8" outside diameter (O.D.) and larger. • No special tooling required for disassembly and reassembly. • Firm, positive lockup of the entire assembly thanks to Curtis’ exclusive visible lock-ring design (the Curtis Tell-Tale Lock Ring). • Built-in lubrication passages with Curtis’ exclusive internal lubrication system. • Lubrication covers (boots) available in all sizes to retain lubricants and keep out contaminants, extending the life of the joint. Curtis joints do not require grooves to be machined on hubs to retain boots. • Maximum wear with less galling and seizing because Curtis uses dissimilar materials on all bearing surfaces. • Soft hubs for easy machinability • Smooth operation and longer life assured by close and well-controlled tolerances between mating parts and Curtis’ built-in lubrication system. • Hubs ground on center for perfect concentricity. Centering holes are provided on solid hubs to aid in machining. • Operating angles of up to 35° on single joints and 70° on double joints.

Open the catalog to page 1All Curtis Universal catalogs and technical brochures

-

boot kits & lubrication

1 Pages

-

Replacement Parts

1 Pages

-

the entire catalog

20 Pages

-

Stainless Steel Joints

2 Pages

-

Curtis Double Joints

2 Pages

-

Alloy Steel Single Joints

2 Pages

-

Catalog

2 Pages