Website:

Cubic Sensor and Instrument Co.,Ltd

Website:

Cubic Sensor and Instrument Co.,Ltd

Group: Cubic

Catalog excerpts

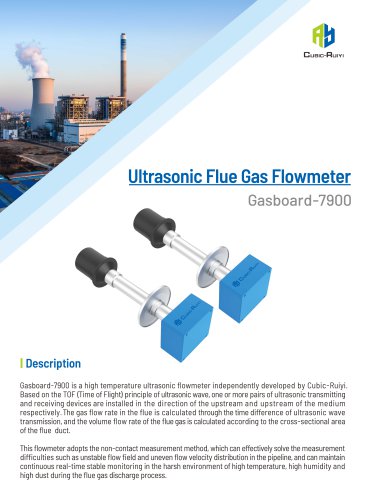

Ultrasonic Technology Introduction Ultrasonic technology can be utilized in gas flow meter and gas concentration sensor. This paper presents the principle and advantages of Ultrasonic measurement to detect gas flow and oxygen concentration and overview of Cubic ultrasonic oxygen sensors. Working principle for flow measurement Ultrasonic oxygen flow meter is to measure the sound waves in the flow of media in the relationship between the time and the flow as the principle. Generally speaking, the actual propagation velocity of the acoustic wave in the fluid is composed of the component of the propagation velocity of the sound waves in the stationary state of the medium and the axial average velocity of the fluid in the direction of acoustic wave propagation weight. As shown in below Figure, the relationship between the downstream and counter current propagation times and the quantities is: Working principle for concentration measurement Ultrasonic concentration detection theory: when the binary gas mixture composition has molecular weight difference, sound travel speed varies from different gas composition. Advantages ◆No need calibration in application ◆Long lifetime, around 5-10 years ◆Compact size, easy to install ◆Low cost, high accuracy, good stability ◆Gas concentration and flow can be measured together Wuhan Cubic Optoelectronics Co., Lt

Open the catalog to page 1All Cubic Sensor and Instrument Co. catalogs and technical brochures

-

Cubic TDLAS CH4 Sensor

4 Pages

-

Gasboard-7500H-OPC

13 Pages

-

NDIR CO2 Sensor Module-CM1106LS

18 Pages

-

Laser Particle Sensor-PM2008M-M

22 Pages

-

Laser Particle Sensor-PM2012

19 Pages

-

Test Instruction of AM4100-I

7 Pages

-

Test Instruction of AM1008W

7 Pages

-

Test Instruction of PM5000

7 Pages

-

Test Instruction of PM1006

8 Pages

-

Test Instruction of CM1107T

7 Pages

-

Test Instruction of CM1107BN

8 Pages

-

Test Instruction of PM3006T

7 Pages

-

Test Instruction of PM2009

8 Pages

-

Test Instruction of CM1106SH

8 Pages

-

Test Instruction of CM1107

8 Pages

-

Test Instruction of CM1106S

8 Pages

-

Test Instruction of CM1106LS

8 Pages

-

Laser Particle Sensor-PM2008

21 Pages

-

Laser Particle Sensor-PM2009

20 Pages

-

Laser Particle Sensor-PM2105-M

20 Pages

-

NDIR CO2 Sensor Module-CM1106S

18 Pages

-

Gas Sensor Line-up

1 Pages

-

About Cubic

1 Pages

-

CEMS Solution - Gasboard 9050

22 Pages

-

NDIR CO2 Sensor Modules

7 Pages

-

Gasboard-7020

4 Pages

-

Gasboard-7500

7 Pages

-

Mainstream ETC02 module

5 Pages

-

Gasboard 3400P

5 Pages

-

Analyzer Gasboard 3800P

6 Pages

-

LANDFILL APPLICATIONS

8 Pages

Archived catalogs

-

Air quality monitor AM7000

11 Pages

-

RHB Series

8 Pages

-

Ultrasonic Flow meter 7200

1 Pages

-

Syngas portable analyzers

4 Pages

-

Opacity meter

1 Pages

-

Infrared Methane gas sensor

3 Pages