Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

Catalog excerpts

CROSS+MORSE Power Transmission Solutions Transmissions Catalogue INDEX BACK NEXT

Open the catalog to page 1

Cross & Morse was established in 1984 through the amalgamation of two long standing and well respected companies in the Power Transmission Industry, T.D.Cross and Morse Chain. T.D. Cross & Sons was founded in 1870 in Birmingham, concentrating in the production of bicycle components under the direction of the Cross family. They moved to the current factory site in 1950 and developed into production of a popular range of roller chain sprockets and gearing. The Morse Chain Company was founded in 1894 also for the manufacture of bicycles in Pennsylvania, U.S.A. The company moved into production...

Open the catalog to page 2

Power Transmission Solutions Cross & Morse Chain Drive Products 2-3 American Standard: - Double Pitch Chains 25-27 - Stainless Steel Chains 28 British Standard: - Double Pitch Chains 15 - Stainless Steel Chains 18 - Corrosion Resistant Roller Chains 18 - Stainless Steel Roller Chain Attachments 19 Centre Distance Calculations 9 Chain Drive Ratios 8 Drive Design Data 94 Food Processing Chains 29 Formulae - Conversion Factors 94 Inverted Tooth Chain & Sprockets Platewheel Adaptor Hubs 69-70 Roller Chain - Cross+Morse Specification: 4 Roller Chain Sprockets: Sintered Bush Chain 24 - American...

Open the catalog to page 3

Power Transmission Product Range Fax The Power Transmission Spectrum Cross+Morse manufacture and supply a complete line of drives to meet the challenge of modern industry, where ever increasing powers, and speeds are required in production machinery combined with precision timing. Cross+Morse offer:- Roller Chain - for high torque drives at low to Silent Chain HV Chain Timing Belts Gears +44(0) 121 360 0155 SILENT CHAIN P - POWER The graph alongside shows a typical power comparison T BEL NG between drives of a similar size. Gears are excluded, as by TIMI design they can be manufactured to...

Open the catalog to page 4

Power Transmission Product Range CROSS+MORSE Te l +44(0) 121 360 0155 Sprockets and Drive Accessories A comprehensive range of pilot bored sprockets, chain wheels, and platewheels is available from stock, all of which can be supplied modified to suit customers shafting. For the more popular BS Chain sizes, taper bored sprockets are also available. To complete the drive is a range of self adjusting and rigid tensioners. Pilot bore sprockets and chainwheels for BS Chains, 05B-1 (8mm) to 32B-3 (2”). Pilot bore sprockets for ANSI Chains, ANSI 35 (3/8”) to ANSI 80 (1”). Stainless steel pilot...

Open the catalog to page 5

sales@crossmorse.com Email +44(0) 121 325 1079 Fax +44(0) 121 360 0155 Te l Cross+Morse Roller Chain Drives CROSS+MORSE Cross+Morse manufacture and stock a comprehensive range of Precision Roller Chain Drives, conforming to both British Standard (BS) and American Standard (ANSI) dimensions within ISO 606; in pitch sizes from 6mm to 3” in simplex and multistrand versions. The chains are capable of handling powers from fractional to over 1000 kW, with operating speeds up to 25 metres per second. Cross+Morse Chains feature higher fatigue resistance and endurance limits achieved by using the...

Open the catalog to page 6

Roller Chain Drive Design Roller Chain by nature of its design is capable of transmitting high torque loads, and provides the ideal drive media for the connection of slow to medium speed shafts located on extended centres. The selection and application is reasonably simple by following normal engineering practices, but there are points of good design practice specific to Roller Chain Drives, and consideration of these will ensure successful drive design. • Numbers of Teeth in Sprockets Chordal Action:- As a chain engages and disengages with a sprocket there is a rise and fall of each link,...

Open the catalog to page 7

Roller Chain Drive Design • Shafts Centre Distance For optimum chain life shaft centres within the range 30 to 50 times chain pitch should be used, refer to page 9. Drives with centres up to 80 times pitch will perform satisfactorily providing adequate adjustment of chain tension is available. For very long centres, consideration should be given using two stage drive with idler, or alternatively for lightly loaded, slow speed (up to 1 m/s) drives, supporting both strands of chain on chain guides. Long Centre Drive using Supporting Guides • Centre Distance Adjustment When designing a chain...

Open the catalog to page 8

Roller Chain Drive Selection Selection Procedure for Chain Drives with Two Sprockets This selection procedure and the chain ratings will provide for a life expectancy of 15,000 hours for drives which incorporate a method of adjustment for wear, are operating in a clean environment at normal ambient temperatures, and subject to proper maintenance and adequate lubrication at all times. In order to use the selection procedure it is first necessary to assemble all data relevant to the application, which should b. Input shaft speed, and output speed required or drive ratio. c. Type of driver and...

Open the catalog to page 9

Roller Chain Drive Selection 3. Chain Size Selection Having determined values for factors fi, h and f> (if applicable), the design Power can be determined. By relating the design Power Pj with the rotational speed of the small sprocket m on the Capacity Chart pplO/11 the correct size of chain for the application can be selected. Use the Capacity Charts to select the smallest pitch of simplex chain which will transmit the design Power, as this normally provides the most economic selection. However, other factors should also be considered when making this selection. a. The preferred centre...

Open the catalog to page 10

Centre Distance Calculations For chain drives incorporating two sprockets, and given an approximate shaft centre distance, the following procedures can be used to determine chain length and actual centre distance. A. Determining number of pitches in chain. 1. For drives where sprockets have same number of teeth. Chain Length Pitches LC = 2 Ao + z 2. For drives where sprockets have different number of teeth. a. Divide the centre distance Ao mm by pitch chain p mm b. Add teeth in the small sprocket Zi to the teeth in the c. Subtract the teeth in the small sprocket Zi from the teeth d. Chain...

Open the catalog to page 11All Cross & Morse catalogs and technical brochures

-

Taper Bushes

2 Pages

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

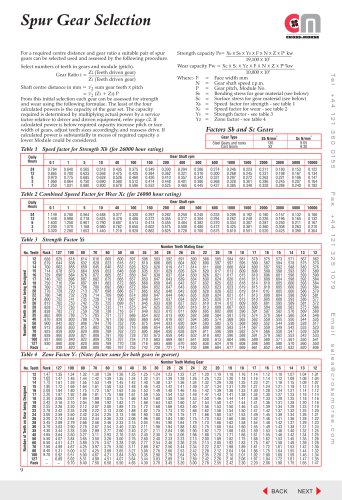

Spur Gears

4 Pages

-

Bevel and Mitre Gears

6 Pages

-

Torque Limiters & Couplings

6 Pages

-

KE Couplings

2 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

Clamping Elements RCK 10-12

2 Pages

-

'M' Series Sprag Clutches

2 Pages

Archived catalogs

-

Gold bearing products

209 Pages

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Shaft Couplings

22 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages