Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

Catalog excerpts

Taper Bushes Taper bushes provide a low cost, simple, quick method of securing sprocket, pulleys and couplings to a wide range of standard metric and imperial dimensioned shafts of general commercial tolerances and finish. The taper surfaces on the bush and mating hub are driven together by high tensile screws, causing the split bush to be firmly contracted onto the shaft. The strong clamping force which can be achieved enables transmission of high torque without the problems of fretting associated with simple keyseated drives. The design ensures quick, easy installation of sprockets and pulleys onto shafts with simple positioning for alignment. Positive jacking-off of the bush during removal ensures quick disassembly without normal problems of seizure between shaft and pulley. The standard bushes shown opposite are suitable for taper bore pulleys shown on pages 35-36. Remove protective coating from the bore and outside bush, and bore of hub. After ensuring the mating tapered surfaces are completely clean, insert bush in hub so that holes line up. Oil thread and point of grub screws, or thread and under head of cap screws. Place screws loosely in holes threaded in hub, shown thus in diagram. Slacken all screws by several turns, remove one or two according to number of jacking off holes thus in diagram. Insert screws in jacking off holes after oiling thread and point of grub screws or thread under head of cap screws. Tighten screws alternately until bush is loosened in hub and assembly is free on the shaft. Clean shaft and fit hub and bush to shaft. Locate in position, remembering bush will nip the shaft first and then hub will be drawn on to the bush. Remove assembly from shaft. Using a hexagon wrench tighten screws gradually and alternately until all are pulled up very tightly. Use a piece of pipe on wrench to increase leverage. When a key is not used, hammer against large end of bush using a block or sleeve to prevent damage. Screws will now turn a little more. Repeat this alternate hammering and screw tightening once or twice. After drive has run under load for a short time, check tightness of screws. If a key is to be fitted, do so after the bush has been tightened on to the shaft, and then fit a parallel key that is side fitting with top clearance. Fill empty holes with grease to exclude dirt. Instructions - Installation and Removal Bush with 3 Grub Screws (Sizes 3535 and above) Installation and Design Recommendations It is recommended that a key should be fitted with bushes in rigid and flexible couplings, timing belt and chain drives, and wherever loads of a heavy pulsating nature are encountered. All keyways are parallel keyways to British Standard 4235 Part 1 : 1972 for metric dimensional shafts, or British Standard 46 Part 1 : 1958 for imperial dimensional shafts, with the exception of those marked* in the tables which are slightly shallower. Where a key is used it should be parallel type with side fitting and top clearance. It is not recommended to use taper bushes with maximum or minimum bore sizes on drives where high shock loads may be encountered. Bush with 2 Grub Screws

Open the catalog to page 1

Taper BushesBush Dimensions Bush No. +Bore size 65mm has keyway 2.3mm deep on 2525 Bush * Shallow Key not to B.S. 46 Part 1.

Open the catalog to page 2All Cross & Morse catalogs and technical brochures

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

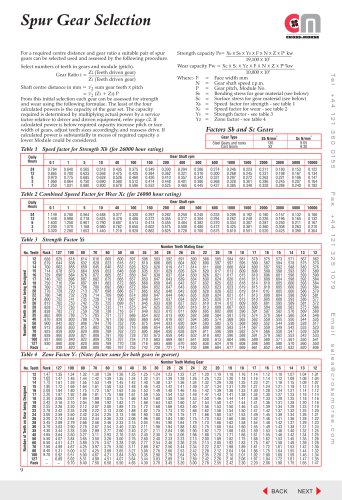

Spur Gears

4 Pages

-

Bevel and Mitre Gears

6 Pages

-

Torque Limiters & Couplings

6 Pages

-

KE Couplings

2 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

Clamping Elements RCK 10-12

2 Pages

-

'M' Series Sprag Clutches

2 Pages

Archived catalogs

-

Gold bearing products

209 Pages

-

Transmissions

90 Pages

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Shaft Couplings

22 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages