Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

Catalog excerpts

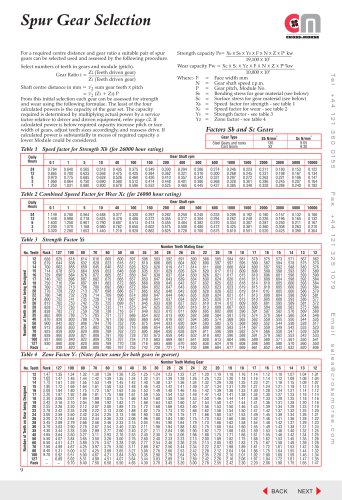

Spur Gear Selection For a required centre distance and gear ratio a suitable pair of spur gears can be selected used and assessed by the following procedure. Select numbers of teeth in gears and module (pitch). Gear Ratio i = Z2 (Teeth driven gear) Z1 (Teeth driven gear) Factors Sb and Sc Gears Gear Type Steel Gears and racks Cast Gears Table 1 Speed factor for Strength Xb (for 26000 hour rating) Daily Hours Table 3 Strength Factor Ys 100 Number of Teeth on Gear being Designed Table 4 Zone Factor Yz (Note: factor same for both gears in gearset) Rack Number of Teeth on Gear being Designed Daily Hours Table 2 Combined Speeed Factor for Wear Xc (for 26000 hour rating) Shaft centre distance in mm = 1 /2 sum gear teeth x pitch = 1 /2 (Z1 + Z2) P From this initial selection each gear can be assessed for strength and wear using the following formulae. The least of the four calculated powers is the capacity of the gear set. The capacity required is determined by multiplying actual power by a service factor relative to driver and driven equipment, refer page c2. If calculated power is below required capacity increase pitch or face width of gears, adjust teeth sizes accordingly, and reassess drive. If calculated power is substantially in excess of required capacity a lower Module could be considered. Strength capacity Ps= Xb x Sb x YS x F x N x Z x P2 kw 19,100 x 103 Wear capacity Pw = Xc x Sc x YZ x F x N x Z x P1.8kw 10,000 x 103 Where:- F = Face width mm N = Gear shaft speed r.p.m. P = Gear pitch, Module No. Sb = Bending stress for gear material (see below) Sc = Surface stress for gear material (see below) Xb = Speed factor for strength - see table 1 Xc = Speed factor for wear - see table 2 YS = Strength factor - see table 3 YZ = Zone factor - see table 4

Open the catalog to page 1

Standard Spur Gears B Dimensions tables for Spur Gears 1.0 and 1.5 Mod. All gears machined from medium carbon, induction hardening steels. Suffix of Cat. No. indicates gear type Gear Widths Pitch Bore Max. Bore No. Teeth Pitch Dia. Min d dp

Open the catalog to page 2

Standard Spur Gears B Dimensions tables for Spur Gears 2.0 to 6.0 Mod. Bore Max. Bore No. Teeth Pitch Dia. Min d dp Suffix of Cat. No. indicates gear type All gears machined from medium carbon steels.

Open the catalog to page 3

Standard Spur Gears 3.0 Mod Spur Gears Cat. No. Bore Max. Bore No. Teeth Pitch Dia. Min d dp Bore Max. Bore No. Teeth Pitch Dia. Min d dp Bore Max. Bore No. Teeth Pitch Dia. Min d dp

Open the catalog to page 4All Cross & Morse catalogs and technical brochures

-

Taper Bushes

2 Pages

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

Bevel and Mitre Gears

6 Pages

-

Torque Limiters & Couplings

6 Pages

-

KE Couplings

2 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

Clamping Elements RCK 10-12

2 Pages

-

'M' Series Sprag Clutches

2 Pages

Archived catalogs

-

Gold bearing products

209 Pages

-

Transmissions

90 Pages

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Shaft Couplings

22 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages