Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

Catalog excerpts

Te l : + 4 4 1 2 1 3 6 0 0 1 5 5 F a x : + 4 4 1 2 1 3 2 5 1 0 7 9 E m a i l : s a l e s@c r o s s m o r s e . c o m Index Shaft Couplings Contents Page Coupling Selection 2 Low Backlash Jaw Couplings: ‘GE’ Series 3 Elastomeric Jaw Couplings: ‘L’ Series 4-5 Jaw Couplings Dimensions: ‘L’ Series 5 Heavy Duty Elastomeric Jaw Couplings: ‘KE’ Series 6-7 Roller Chain Couplings: ‘LRC’ Series 8-9 Delrin Chain Couplings: ‘LNC’ Series 10-11 Gear Couplings: ‘GFA’ & ‘GFAS’ Series 12 Polymer Gear Couplings: ‘GF’ Series 13 Morflex Elastomeric Disc Drive Couplings 14 Crossflex Disc Couplings: 15 - Selection Procedure 16 - ‘CF’ Series Dimensions 17-19 - L & M With Avante Clamping Elements 20 1 BACK NEXT

Open the catalog to page 1

2 Coupling Power Range Speed Range Shaft Size Max. Angular Max. Parallel Max. Torsional Type kw rpm mm Misalignment Misalignment mm End Float mm Stiffness Heavy Shock - 8 hr./day Blowers (centrifugal), Compressors (reciprocating), Crushers, Feeders, 2.5 2.8 3.2 Reversing under full load Hammer Mills, Hog Drives, Presses, Pumps (reciprocating, oil well), High Starting torque Tractors, Trucks, Winches Uneven load - 8 hr./day Beaters, Cranes, Compressors (centrifugal), Elevators (bucket), 1.5 2 2.5 Moderate shock or torque Grinders (pulp), Hoists, Kilns, Mills (ball, rolling, pebble, tube),...

Open the catalog to page 2

GE19AA-24BA - 19 12 24 32 40 40 25 16 19 12 18 66 0.12 0.13 0.14 0.3 0.4 0.4 GE24AA-32BA 6 24 14 28 40 55 55 30 18 24 14 27 78 0.24 0.26 0.28 0.8 0.9 1.0 GE28AA-38BA 7 28 16 38 48 65 65 35 20 27.5 15 30 90 0.39 0.46 0.53 2.0 2.4 2.8 GE38AA-45BA 8 38 20 45 66 78 80 45 24 36.5 18 38 114 0.82 0.89 0.95 7.0 7.5 8.0 GE19A-24B 14000 10 2.6 0.68 0.57 0.44 0.28 1.2° 0.2 1.2 GE24A-32B 10600 35 9 2.19 1.82 1.40 0.90 0.9° 0.2 1.4 GE28A-38B 8500 95 25 5.20 4.31 3.32 2.12 0.9° 0.25 1.5 GE38A-45B 7100 190 49 10.00 8.30 6.39 4.08 1.0° 0.28 1.8 GE42A-55B 6000 265 69 17.00 14.11 10.68 6.94 1.0° 0.32 2.0...

Open the catalog to page 3

4 Buna-N Excellent Excellent Good – –40 to 100 1° 0.4mm Urethane Good Good Good Good –35 to 70 1° 0.4mm Hytrel® Fair Fair Excellent Excellent –50 to 120 1/2° 0.4mm Bronze – – Excellent Excellent –40 to 230 1/2° 0.25mm ‘L’ Series Jaw Couplings Simple, economical design - fully interchangeable with industry standards. Cross has expanded its comprehensive family of quality industrial couplings to include the Type ‘C’ Jaw...offering a uniquely simple design combined with misalignment capability and maximum economy. ‘L’ coupling contain only three components...two jaws and one ‘spider’ insert....

Open the catalog to page 4

Coupling SIze KE Series Elastomeric Couplings 6 The KE coupling is a general-purpose flexible coupling, fully interchangeable with the standard couplings frequently used throughout the industry. The coupling consists of two machined cast iron hubs connected by an elastomeric gear ring. Available in 8 basic sizes, with torque capacity to 3300 Nm, the KE coupling provides positive power transmission between shafts, combined with the ability to accommodate moderate levels of misalignment. KE couplings are designed to transmit torques equal to the capabilities of sizes of commercial shafting...

Open the catalog to page 6

Te l : + 4 4 1 2 1 3 6 0 0 1 5 5 F a x : + 4 4 1 2 1 3 2 5 1 0 7 9 E m a i l : s a l e s@c r o s s m o r s e . c o m KE 7 33 73 7700 1.0 0.3 +0.2 9 84 185 6300 1.0 0.3 +0.5 11 168 370 5000 1.0 0.3 +0.6 13 331 725 4100 1.0 0.4 +0.8 15 630 1490 3600 1.0 0.4 +0.9 18 998 2300 3000 1.0 0.4 +1.1 23 2100 4800 2600 1.0 0.5 +1.3 28 3300 7000 2200 1.0 0.5 +1.7 Coupling No. KE Series Couplings 7 KE Couplings Dimensions and Technical Specification The KE couplings are available with solid hubs for reworking, ‘type B’; or taper bored hubs for standard taper bushes. The taper bored hubs can be provided...

Open the catalog to page 7

8 Misalignment Maximum angular misalignment is 1°, but for maximum life angular misalignment should not exceed 1/2°. Refer to sketch on right, where .009mm per mm root dia. is equivalent to 1/2° angular misalignment. B – A = .009 x C. Offset or Parallel misalignment should not exceed 2% of chain pitch. LRC 12030 18040 94.0 180.0 324.0 490.0 630.0 830.0 995.0 Roller Chain Couplings Cross & Morse Roller Chain Couplings consist of three high strength components; two special chain sprockets manufactured from high quality medium carbon alloy steels connected by a length of high strength Duplex...

Open the catalog to page 8

Te l : + 4 4 1 2 1 3 6 0 0 1 5 5 F a x : + 4 4 1 2 1 3 2 5 1 0 7 9 E m a i l : s a l e s@c r o s s m o r s e . c o m 9 12016 38.1 105 186 156 81 105 230 24 29.0 12020 50.8 120 178 175 77 105 278 24 53.0 12024 50.8 150 231 232 103 105 326 24 76.0 12030 50.8 200 231 302 103 105 398 24 137.0 Base Approx. Cover To suit all couplings Weight No. kg AL 40 AL 4016K LRC 4016 51 102 0.45 AL 50 AL 5016K LRC 5016 60 130 0.70 AL 50 AL 5018K LRC 5018 TB 5018 60 130 0.70 AL 60 AL 6018K LRC 6018 75 162 1.25 AL 80 AL 8018K LRC 8018 102 208 2.40 AL 80 AL 8020K LRC 8020 TB 8020 102 208 2.35 Cover No. To Suit...

Open the catalog to page 9

12 GFA and GFAS Gear Couplings Coupling types GFA and GFAS are designed for heavy industrial applications, providing a torsionally stiff connection of shafts which can accommodate angular and parallel misalignment and axial movement. The GFA coupling consists of two hardened steel hubs with external crowned and barrelled gear teeth, connected by a hardened steel sleeve with matching gear teeth. The hub teeth are positioned a maximum distance apart to minimise angular and parallel misalignment. The double articulation in the GFA series permits high misalignment. The GFAS coupling has only...

Open the catalog to page 12

Te l : + 4 4 1 2 1 3 6 0 0 1 5 5 F a x : + 4 4 1 2 1 3 2 5 1 0 7 9 E m a i l : s a l e s@c r o s s m o r s e . c o m 13 Type GF Gear Couplings Low cost, gear couplings for lower power applications, available in 10 sizes with torque capacity to 410Nm and shaft speeds up to 14,000 rpm. The GF Coupling consists of two steel hubs with external crowned and barrelled gear teeth, phosphated for corrosion protection, connected by a synthetic resin sleeve. The sleeve is manufactured from high molecular weight polyamide, thermally conditioned and impregnated with solid lubricant to provide a long...

Open the catalog to page 13All Cross & Morse catalogs and technical brochures

-

Taper Bushes

2 Pages

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

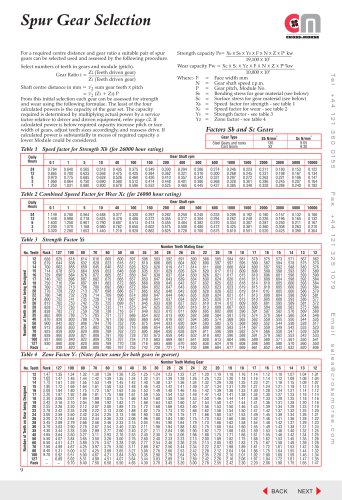

Spur Gears

4 Pages

-

Bevel and Mitre Gears

6 Pages

-

Torque Limiters & Couplings

6 Pages

-

KE Couplings

2 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

Clamping Elements RCK 10-12

2 Pages

-

'M' Series Sprag Clutches

2 Pages

-

Gold bearing products

209 Pages

-

Transmissions

90 Pages

Archived catalogs

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages