Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

Catalog excerpts

KE Series Elastomeric Couplings The KE coupling is a general-purpose flexible coupling, fully interchangeable with the standard couplings frequently used throughout the industry. The coupling consists of two machined cast iron hubs connected by an elastomeric gear ring. Available in 8 basic sizes, with torque capacity to 3300 Nm, the KE coupling provides positive power transmission between shafts, combined with the ability to accommodate moderate levels of misalignment. KE couplings are designed to transmit torques equal to the capabilities of sizes of commercial shafting which can be accommodated. Available either with parallel bore or with taper bush, these couplings are quick and easy to assemble with the machined outer flanges enabling simple alignment with just a straight edge. The elastomeric gear ring is moulded in Pebax R Polyether which is oil resistant, has a partial resistance to chemicals, and a low moisture absorption rate. The gear ring cushions transient peak torques, effectively reducing transmission of operational vibrations and shock loads. Standard couplings can be operated in environmental temperatures ranging from –40˚C to +85˚C. Refer to page 2 for standard procedure for coupling selection. The number of starts to which an KE coupling is subjected will affect its life, and it is thus necessary to modify the design power Pd for drives subject to more than 4 starts per day by factor f. in table, to get selection power Ps. Thus No. starts/day KE Coupling Selection Procedure kW Power Ratings - Standard KE Couplings Coupling SIze 7 Dynamic balancing required for shaft speeds over 3600 rpm *For shaft speeds below 100 rpm use nominal torque Tn. Maximum shaft speeds of coupling controlled by safe max. peripheral speed for cast iron. Email: sales@crossmorse.com

Open the catalog to page 1

KE Series Couplings KE Couplings Dimensions and Technical Specification The KE couplings are available with solid hubs for reworking, ‘type B’; or taper bored hubs for standard taper bushes. The taper bored hubs can be provided with the bush fitting from the hub end, ‘type H’, or from the flange end, ‘type F’, to enable easy fitting to end of motor/gearbox shafts. J = Dimension of clearance required to remove hub using Jack screw with shortened hex. key. Coupling Capacities Coupling No. Maximum Torque Maximum Misalignment Angular degrees Nominal Torque *It is preferable to dynamically...

Open the catalog to page 2All Cross & Morse catalogs and technical brochures

-

Taper Bushes

2 Pages

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

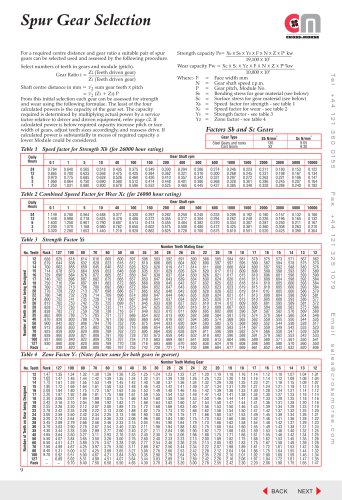

Spur Gears

4 Pages

-

Bevel and Mitre Gears

6 Pages

-

Torque Limiters & Couplings

6 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

Clamping Elements RCK 10-12

2 Pages

-

'M' Series Sprag Clutches

2 Pages

-

Gold bearing products

209 Pages

-

Transmissions

90 Pages

Archived catalogs

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Shaft Couplings

22 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages