Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

Catalog excerpts

GE Series Elastomeric Couplings For GE Series Couplings design torque may need correcting for elevated ambient temperature or frequent starting before comparison with the coupling nominal torque rating. Coupling nominal torque f1 = temperature factor f2 = start-up factor Ts = starting/max torque of motor For applications with frequent torque changes or reversal, check capacityTr Reversal Torque TrTv.f1. Tv = actual torque variation GE Plain Bore Couplings - Capacities and Dimensions (mm) Technical Data Nominal(3) Reversal Torque Torque Tn Nm Tn Nm Torsional Stiffness kNm/Rad 1.0 Tn Maximum Misalignment Performance ratings for Aluminium Hubs are identical to equivalent steel size. Dimensions Coupling (1) Size Bore Diameters - mm Hub Type A Hub Type B Min. Max(2) Min. Max(2) Type A-A Type A-B Type B-B Type A-A Type A-B Type B-B (1) Coupling ref is for mixed hubs. (4) With coupling correctly positioned on shafts. (5) Weights and Inertias for couplings on max. bore. (2) With Standard keyway. (3) Angular deflection at Nominal Torque Tn is 3˚ and Max Torque Tm is 5˚ Max Torque is double Nominal Torque. All Couplings can be supplied with hubs finished bored, keyseated and with set screws on 48 hour re-work service. Also sizes 28A- 38B through to GE75A - 90B are available with Taper Bush fitting. Email: sales@crossmorse.com Coupling Capacities and Selection The GE series of flexible couplings consist of two machined metal hubs connected by an elastomeric gear ring. The couplings are equally suited to horizontal or vertical shaft applications, providing positive power transmission and absorbing torsional, vibration and impact loads. The standard elastomeric ring is a black thermoplastic rubber of 94 shore A hardness selected for its resistance to wear, oil, chemicals, ozone and hydrolysis, which makes it suitable for tropical climates. Standard couplings can work in environments with temperature range –40˚C to +125˚C and withstand +150˚C for short periods. The teeth of the gear ring are of involute form to prevent high stress concentrations in reduced surfaces, and crowned to avoid edge pressure on the teeth. The circular apertures on each hub are precision-machined to provide positive torque transmission with minimum backlash. For increased torsional rigidity two alternative gear rings are available, both of 96 Shore a hardness; a red thermoplastic rubber element, and a yellow polyurethane element recommended for the Aluminium Hubs. GE Plain Bore Couplings are manufactured in two materials, Grade 250 Cast Iron for normal industrial applications, and aluminium where weight and inertias must be kept to a minimum. Two styles of hub are offered: ‘ ’ style with hub diameter A reduced below flange diameter to minimise weight; and ‘B’ style with hub diameter basically the same as the flange diameter to accommodate larger diameter shafts of electric motors and gear units. Different styles of hub can be mixed to accommodate differing shaft requirements. The hubs are identified by the maximum bore which can be accommodated, and hub style, i.e. GE24A is an ‘ ’ type hub capable of max. bore size 24mm. Hubs of different styles can be combined in a coupling, and identified as A in examples below. GE24A-24A - Has two ‘ ’ type hubs. A GE24A-32B - Has one ‘ ’ and one ‘B’ type hub. A For aluminium couplings numbers are the same with addition of a suffix ‘ ’ e.g. GE24AA-32BA A

Open the catalog to page 1All Cross & Morse catalogs and technical brochures

-

Taper Bushes

2 Pages

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

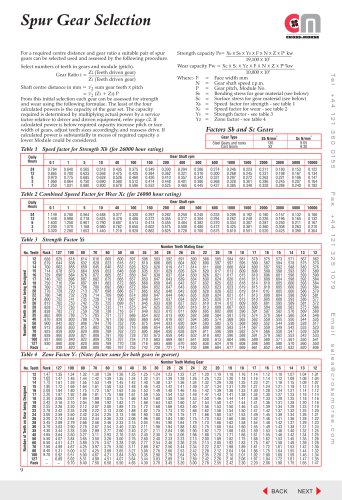

Spur Gears

4 Pages

-

Bevel and Mitre Gears

6 Pages

-

Torque Limiters & Couplings

6 Pages

-

KE Couplings

2 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

Clamping Elements RCK 10-12

2 Pages

-

'M' Series Sprag Clutches

2 Pages

Archived catalogs

-

Gold bearing products

209 Pages

-

Transmissions

90 Pages

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Shaft Couplings

22 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages