Catalog excerpts

Technical Datasheet DEPA DH® Next Generation Air Operated Double Diaphragm Pumps www.depapumps.com www.cranecpe.com

Open the catalog to page 1

Features and Benefits DEPA DH® Next Generation Air Operated Double Diaphragm Pump Series DH15, DH25, DH40, DH50 and DH80 are made of cast aluminum developed for industrial applications. Flexible Multiport-Connections Innovative Flange-Design • A customized manifold design that improves ball valve guidance, increases functionality and provides up to 25 different installation options • Error free assembling in combination with singlecenter block • Multi-porting provides many options for installation e.g.: - Vertical orientation can be easily used for emptying of drums - No additional adapters...

Open the catalog to page 2

Features and Benefits Applications The aluminum housing material with universally selectable interior allows versatile application possibilities. For instance in • Painting- and coating industries • Printing- and gluing machines • Mechanical engineering and construction • Automotive Operation temperature of aluminum -10°C to +130°C. Further limitations are according to interior of pump, see table with product wetted interior Product wetted interior DEPA DH® Next Generation Air Operated Double Diaphragm Pumps of aluminium series are available in nominal sizes of ½” (DH15), 1”(DH25), 1 ½”...

Open the catalog to page 3

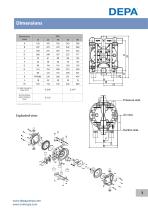

Pump Sizes and Equipment DH Material Options Connecting Dimension DH (mm) / inch Housing Material Valve Seat Valve Ball Stainless Steel 1) Not for size 15 Further material options are available upon request Product Ports / Orientation of Manifolds Discharge Port S1 (inlet from bottom) S4 (inlet at opposite side of air inlet) S5 (inlet left hand side / view to air inlet) S3 (inlet right hand side / view to air inlet) S2 (inlet aligned with air inlet) Suction Port (outlet left hand side / view to air inlet) (outlet at same side as air inlet) outlet right hand side / view to air inlet) (outlet...

Open the catalog to page 4

Air inlet Internal Air Valve (inch) Air inlet AirSave Sytem (M-Valve) (inch) Pressure side 1) External DEPA® AirSave System Exploded view

Open the catalog to page 5

Performance Curves Example for pump selection Required is 2 m³/h as the flow rate at a discharge pressure of 4 bar. Recommend is the DH25 for this application. The needed air supply pressure is 4,3 bar. This equals an air consumption rate of 13 m³/h (between QI = 10 m³/h and QI = 20 m³/h). Discharge Pressure Discharge Pressure Discharge Pressure Discharge Pressure Operating Point Discharge Pressure Curves are based on internal Air Valve only

Open the catalog to page 6

Available Accessories DEPA® AirSave System An innovative and robust DEPA® AirSave design increases the energy efficiency and service life of the pump. It delivers outstanding performance and operates at a low start-up pressure with hardly any leakage. Shorter maintenance downtime and reduced number of spare parts decreases the operating costs. The AirSave System is diversified for a broad range of applications. It is compatible with DEPA® Type DL-Series Polypropylen, Sizes 15/25/40 and with Type DH-Series Aluminium, Sizes 15/25/40. ATEX compliant if in combination with ATEX conform DEPA®...

Open the catalog to page 7

Crane ChemPharma & Energy Crane Process Flow Technologies GmbH Heerdter Lohweg 63-71, D-40549 Dusseldorf RLDYK) covrgi-'ivE COMPAC-NOZ" ISTOCKHAM M/ang/e UNI-CHEK' W.fa: XOMOX Crane Co., and its subsidiaries cannot accept responsibility for possible errors in catalogues, brochures, other printed materials, and website information. Crane Co. reserves the right to alter its products without notice, including products already on order provided that such alteration can be made without changes being necessary in specifications already agreed. All trademarks in this material are property of the...

Open the catalog to page 8All Crane Process Flow Technologies GmbH catalogs and technical brochures

-

DEPA Serie L

12 Pages

-

DEPA Nopped S4

2 Pages

-

DEPA Nopped E4

1 Pages

-

DEPA AirSave System

2 Pages

-

angle valve

52 Pages

-

CRANE BALL VALVE

16 Pages

-

CV 1000

32 Pages

-

COMPAC-NozTM

4 Pages

-

DUO-CHEK II Check Valves

8 Pages