Catalog excerpts

Brochure DEPA® Air-Operated Double Diaphragm Pumps www.d epapumps.com

Open the catalog to page 1

Legacy of Innovation Legacy of Innovation and Customer Service Designed and manufactured for over 40 years in Düsseldorf, Germany, DEPA® Air-Operated Double Diaphragm (AODD) pumps have earned industry recognition for premium quality and innovative design. Focus on customer satisfaction is supported with quality and reliability, validated by ISO 9001 and ISO 14001 certifications. Product Highlights DEPA® offers a wide range of pumps for diverse applications, from standard pumps to highly customized and engineered products, and we supply accessories and components suitable for most AODD pump...

Open the catalog to page 2

Key Features Our Uniquely-Built Pumps Offer These Key Features: Compact design requires fewer components, resulting in lower Interchangeable modular design allows fewer spare parts inventories Special applications can be accommodated by combining our housing and elastomer materials

Open the catalog to page 3

Series M Main Applications • • • • • • Automobile Chemical Ceramic and Porcelain Mining, Building Paint and Varnish Wastewater Series P Main Applications • • • • • • • Chemical Galvanic and Coating Paint and Varnish Pulp and Paper Pharmaceutical Plant and Mechanical Engineering Power Stations and Waste Disposal Technology Series L Main Applications • • • • • • • • Beverage Biotechnology Chemical Cosmetic Dairies Food Medical Applications Pharmaceutical Housing Material Series M Housing Material Series P Housing Material Series L Aluminium : Multi-purpose housing material that is lightweight...

Open the catalog to page 4

Applications Pharmaceutical and Cosmetic Pharmaceutical and Cosmetic process applications call for demanding hygienic standards and efficient “cleanability” of system components. DEPA® pumps accommodate these requirements with their design and polished surfaces, CIP (cleaning in place) & SIP (sterilization in place). (Pictured) DEPA® 1” polished stainless steel pumps for hydrogen peroxide + additives in a hair colour production process Food DEPA® pumps were designed with an unimpeded flow-path, providing smooth transfer of product, which generates minimal shear effect even with large solid...

Open the catalog to page 5

Interchangeable Design A key design concept of our DEPA® Air-Operated Double Diaphragm Pumps is a modular, compact design. Fewer parts lead to pump efficiency thereby reducing downtime and parts inventories. Our pumps can easily be modified to switch from one application to another simply by changing the diaphragms, balls, and seats. Note: The illustration shows the typical arrangement of the clampband version DL. The DH version is refered to as the flanged design as the pump chambers are bolted to the centre block. Housing Material Options FA Aluminium CA Nodular Cast Iron CX Nodular Cast...

Open the catalog to page 6

Interchangeable Design Valve Balls Material Options B NRS E EPDM F FKM G EPDM Grey N NBR R Stainless Steel T PTFE V NRS/Steel Core W EPDM/Steel Core X EPDM Grey/Steel Core Y NBR/Steel Core Z PTFE/Steel Core Valve Seats Material Options B NRS E EPDM F FKM G EPDM Grey H Stainless Steel only DB N NBR R Stainless Steel T PTFE Diaphragms Material Options B NRS E EPDM F FKM G EPDM Grey N NBR P PTFE (DH, Series L only) S DEPA Nopped S4® (Santoprene®) T PTFE U EPDM Grey (DH, Series L only) Z DEPA Nopped E4® (PTFE Compound Diaphragm) DL = Clampband Version DH = Flanged Version DL/DH Pump Type...

Open the catalog to page 7

Air Control Air Valve In applications distributed across the globe, DEPA® Air-Operated Double Diaphragm Pumps are subjected to impressive ranges of operating temperatures, pressure fluctuations, full load, and intermittent operating conditions. This often places severe demands on the air valve responsible for the distribution of air in the individual chambers, therby regulating the operation of the pump. In order to meet the emerging requirements of industry, DEPA® engineers conduct ongoing intensive research and development work to maintain “state-of-the-art” status for our products....

Open the catalog to page 8

Materials and Selection Elastomer Materials (for Diaphragms) The characteristics of various elastomer compounds are taken into account in the selection of diaphragm materials to match the chemical and mechanical requirements of particular applications. The design of DEPA® diaphragms incorporates technological advances developed over years of field experience. Our stateof-the-art manufacturing process directly contributes to the extended lifetime of our diaphragms. A remarkable part of the process is the use of fabric that is integrated during forming within the elastomer, enhancing...

Open the catalog to page 9

Metallic Pumps, Series M - Type DL Overview DEPA® Air-Operated Double Diaphragm Pumps made of cast metal have proven themselves over decades in various industrial applications. The myriad of established applications across the globe include installations on ships, at well-known ceramics manufacturers, in spray painting systems (in the automobile industry), and in mining operations, among countless others. The sturdy cast metal construction provides high resistance to abrasive media and a low flow resistance, owing to its polished surface. They are available in a wide selection of...

Open the catalog to page 10

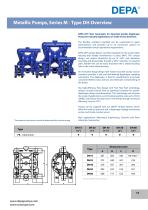

Metallic Pumps, Series M - Type DH Overview DEPA DH® Next Generation Air Operated Double Diaphragm Pumps for industrial applications are made of cast aluminum. The flexible, multiport manifold can be customized to plant specifications and provides up to 25 connection options to accommodate various operational requirements. DEPA DH® pumps feature cast feet integrated in the center block housing that enable maintenance in place (MIP). This unique design can reduce downtime by up to 25%* and optimizes assembly and disassembly through a 30%* reduction in required parts. Rubber feet can be...

Open the catalog to page 11

Non-Metallic Pumps, Series P Overview Series P made of mechanically manufactured or specially injection moulded plastic parts was designed for problem free pumping of corrosive and abrasive products in galvanic applications, in the chemical industry, and in mechanical engineering. Mechanically stable metals do not necessarily possess the required chemical resistance needed for certain corrosive media. For applications needing such resistance, we developed our DEPA® Series P air-operated double diaphragm pump versions that are made of plastic materials. The Series P operating pressure...

Open the catalog to page 12All Crane Process Flow Technologies GmbH catalogs and technical brochures

-

DEPA Serie L

12 Pages

-

DEPA Nopped S4

2 Pages

-

DEPA Nopped E4

1 Pages

-

DEPA AirSave System

2 Pages

-

angle valve

52 Pages

-

CRANE BALL VALVE

16 Pages

-

CV 1000

32 Pages

-

COMPAC-NozTM

4 Pages

-

DUO-CHEK II Check Valves

8 Pages