Website:

Cozzoli Machine Company

Website:

Cozzoli Machine Company

Catalog excerpts

PROVEN VERSATILITY AND RELIABILITY VR2 SERIES LIQUID FILLING The VR2 filler is a reliable, high performance aseptic liquid filling machine, conforming to current cGMPs. This series uses existing overhead laminar air flow to it's fullest - using a straight-line concept and small footprint, effective in maintaining the integrity of a clean room environment. The Cozzoli simple two-piece filling syringes and valve assemblies are designed for sterile, bacteria-free environments. High precision machining of our filling syringes allows each machine to achieve a fill accuracy of +\- 1/2 of 1% by volume, or better. Other fill methods, such as diaphragm, peristaltic, etc. are also available. Changeover for various container heights and nozzle stroke adjustment is made easy, with simple calibrated hand-wheel features. FILL PRINCIPLE Containers are positioned in the machine by a feed screw. A diving nozzle system provides bottom-up filling on a range from 0-4" (101.6mm). This system eliminates the need to change cams and speeds up changeover. A drop control mechanism eliminates a hanging drop at the completion of the fill cycle. VR2/S Monoblock filler/stopper system shown. CONTROLS The PLC controls intermittent container handling through the timing feedscrew. This feedscrew can be set to multidose, which provides maximum production for large fills, or when running foamy products. Control panel shown with optional remote umbilical mount 50 Schoolhouse Road Somerset, NJ 08873-1289 USA Phone: (732) 564-0400 Fax: (732) 564-0444 Email: sales@cozzoli.com www.cozzoli.com

Open the catalog to page 1

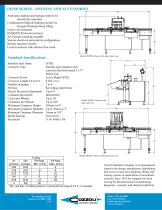

VR2 - OPTIONS AND ACCESSORIES Automatic makeup and backup controls for smooth line operation Combination filling & flushing nozzles for nitrogen flushing during filling Fine adjustment volume control Electronic volume control Dual-track filling for higher speeds Down vial eliminator IQ/OQ/PQ Protocols (written) Air/Vacuum cleaning assembly Various electrical and controls configurations Explosion proof electrical Diaphragm pumps for shear sensitive products ... and more OPTIONS Stainless steel frame Centering devices Full length feed screw or gating Remote operator console Flow meter...

Open the catalog to page 2

VR2PP SERIES LIQUID FILLING MACHINE PROVEN VERSATILITY AND RELIABILITY The VR2PP Series are reliable, high performance aseptic liquid filling machines using peristaltic pump technology. The Cozzoli Peristaltic Pump Filling System utilizes the latest innovations in single-use technology. Advantages include reduced costs, quicker set up, less waste and completely eliminates cleaning process. Designed with Class 100 clean rooms in mind, the VR2PP Series uses a straight line concept with a small footprint and is built for reliability, easy operation and accuracy. The VR2PP models are available...

Open the catalog to page 3

VR2PP SERIES - OPTIONS AND ACCESSORIES Automatic makeup and backup controls for smooth line operation Combination filling & flushing nozzles for nitrogen flushing during filling Down vial eliminator IQ/OQ/PQ Protocols (written) Air/Vacuum cleaning assembly Various electrical and controls configurations Remote operator console Lexan Enclosure with laminar flow hood Model VR2PP-4 shown with tank, front view. Standard Specifications (STD) Sanitary type stainless steel conveyor bed with raised 3 1/4” Delrin Top Conveyor Travel Left to Right (STD) Conveyor Length Ctr to Ctr 8 feet c to c Number...

Open the catalog to page 4All Cozzoli Machine Company catalogs and technical brochures

-

FSV50 - MINI MONOBLOCK

2 Pages

-

MVP

3 Pages

-

Versatile Capping Machine

4 Pages

-

Rotary Piston Filler

3 Pages

-

Rotary Fill-To-Level

2 Pages

-

Inline Piston Filler

2 Pages

-

Inline Liquid Fillers

2 Pages

-

Inline Fill-to-Level

2 Pages

-

Volumetric Inline Filler

3 Pages

-

Rotary Monoblock

3 Pages

-

Powder Fillers Series

2 Pages

-

Inline Liquid Fillers

6 Pages

-

Ampoule Filling and Sealing

2 Pages

-

Syringe Filler

2 Pages

-

Rotary Crimping Machine

2 Pages

-

F400X-SS - TABLE TOP FILLER

2 Pages