Catalog excerpts

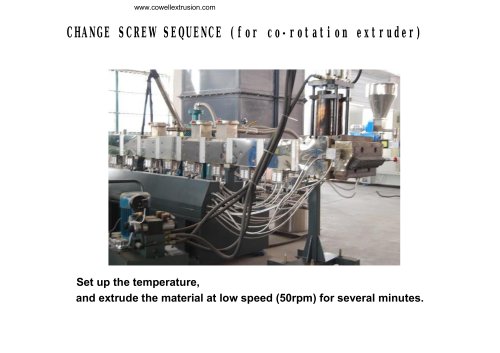

CHANGE SCREW SEQUENCE (for co-rotation extruder) Set up the temperature, and extrude the material at low speed (50rpm) for several minutes.

Open the catalog to page 1

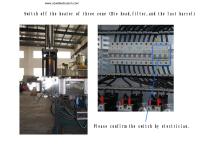

Switch off the heater of three zone(Die head,filter,and the last barrel) Please confirm the switch by electrician.

Open the catalog to page 2

Remove the temperature sensor and heater of the last barrel.

Open the catalog to page 3

Loose the connecting bolts between the barrel and filter, remove the filter and die head together to side, no need disconnect the wire for the filter and die head’s heater and sensor.

Open the catalog to page 4

Remove the plug block on the barrel.

Open the catalog to page 5

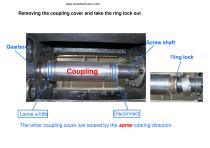

Removing the coupling cover and take the ring lock out Screw shaft Ring lock The other coupling cover are loosed by the same rotating direction.

Open the catalog to page 6

Remove the feeding hopper, and use one big flat screw driver here. Moving the screw out of barrel. If it is hard to remove the screw, need the extra screw driver to do the same from the venting port.

Open the catalog to page 7

If it is still hard to remove the screw. Please remove the screw tips, and fix the special tools, and to pull the screws by several mans. Loose screw tips

Open the catalog to page 8

Put the screw on the wood stick, and clean the screw by steel brush, then remove the screw tips, hit the screw lightly out of shaft by copper or aluminum stick. If it is very hard to hit out the screw elements, please use the fire to melt the material inside the shaft then hit it again.

Open the catalog to page 9

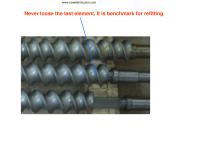

Never loose the last element, It is benchmark for refitting

Open the catalog to page 10

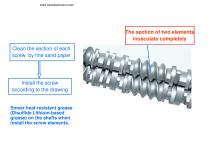

The section of two elements inosculate completely Clean the section of each screw by fine sand paper Install the screw according to the drawing Smear heat-resistant grease (Disulfide Lithium-based grease) on the shafts when install the screw elements.

Open the catalog to page 11

After fix on all the screw elements, the last screw element should be about 10mm longer than shaft, then tight the screw tips. Put one screw into the barrel to clean the barrels. Then blower the dust out of the barrel by compress air. (cover the coupling by clothes, make sure no dust go into the coupling) Tight the adjustable pads.

Open the catalog to page 12

When mix two parallel screws together, the center line of the sections should be 90 degrees. Rotate the screws together for three circles as the above photos. Two screws should be rotated easily without touching with each other.

Open the catalog to page 13

Fix on the screw coupling, one man rotating the main motor coupling slightly (forward and backward), one man persons push the screw from the die until the screw go into the screw coupling totally. Then rotate the main motor coupling 8 circles, make sure it can be rotate smoothly. Main motor coupling

Open the catalog to page 14

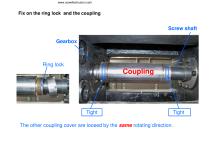

Fix on the ring lock and the coupling Screw shaft Gearbox Ring lock Tight The other coupling cover are loosed by the same rotating direction.

Open the catalog to page 15

1)Clean all the section of the die head and barrel 2)Fix the filter and die head 3)Fix the heater and temperature sensor for the barrel 4)Switch on the heaters. Please contact us for more information if you have any further question Email: info@cowellextrusion.com Tel: +86 25 8615 3639 Fax:+86 25 8103 0096 Mobile/wechat/whatsapp: +86 159 9648 6859 Website: www.cowellextrusion.com

Open the catalog to page 16All Cowell(Nanjing)Extrusion Machinery Co. catalogs and technical brochures

-

Catalog of COWELL EXTRUSION

12 Pages