Catalog excerpts

Science & Technology Flexible glass substrates for continuous manufacturing Corning - S. Garner , G. Merz , J. Tosch, J. Matusick, X. Li , D. Marshall CAMM - C. Chase, J. Steiner, D. Yepez, J. Switzer, P. Moschak February 9, 2011

Open the catalog to page 1

Outline • Flexible glass for electronic devices • Flexible glass mechanical reliability – Strength – Coatings – Stress • Roll-to-roll photolithography • Summary Science & Technology

Open the catalog to page 2

Flexible Glass Enables High-Quality Electronics Substrate choice critical for device fabrication & performance • Substrate integrates designs, materials, & processes – Essential for overall optimization – Glass enables improved resolution, registration, performance & lifetime Flexible glass barrier Flexible glass substrate Flexible Glass •Thermal stability •Dimensional stability •Hermeticity •Optical transmission •Surface roughness Device Designs E-paper, touch sensor, PV, OLED Capabilities Requirements Science & Technology Materials Conductor, semiconductor, dielectric Continuous Processes...

Open the catalog to page 3

Glass Surface & Bulk Properties Optimize Devices Flexible glass device capability demonstrated in <170µm LCD • • • • • Twisted nematic LCD qVGA (320 x RGB x 240) 4”diagonal (80mm x 60mm) Pixel size 83µm x 250µm Aperture 52% • a-Si:H active matrix backplane • TFT channel L=10µm, W=50µm • Polymeric substrates not compatible – 300°C backplane fabrication – 210°C frontplane fabrication • 75µm flexible glass thickness – LC cell <170µm S. Hoehla, et al., “ Color AM-LCDs on Flexible Glass Substrates” IDW 2010, p.1689-1692. Full , Science & Technology

Open the catalog to page 4

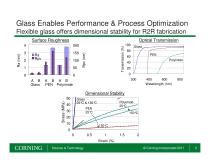

Glass Enables Performance & Process Optimization Flexible glass offers dimensional stability for R2R fabrication Optical Transmission Dimensional Stability 50 Stress (MPa) Strain (%) Science & Technology

Open the catalog to page 5

Mechanical Reliability of Flexible Glass Substrate solutions optimized for continuous processing • Mechanical reliability of glass understood – Failure due to distributions of defects & applied stresses – Bend strength independent of thickness • Mechanical reliability requires controlling defects & applied stress – High strength glass forming including surfaces & edges – Protecting substrate from damage – Managing stresses during conveyance, handling & application Failure Probability (%) Science & Technology 0.10 1 BendRadius (cm) Bend Radius (cm) © Corning Incorporated 2011

Open the catalog to page 6

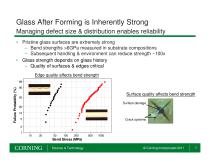

Glass After Forming is Inherently Strong Managing defect size & distribution enables reliability • Pristine glass surfaces are extremely strong – Bend strengths >6GPa measured in substrate compositions – Subsequent handling & environment can reduce strength ~100x • Glass strength depends on glass history – Quality of surfaces & edges critical Edge quality affects bend strength Failure Probability (%) Surface quality affects bend strength Crack systems Bend Stress (MPa) Science & Technology

Open the catalog to page 7

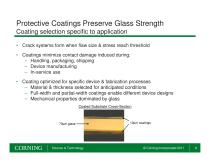

Protective Coatings Preserve Glass Strength Coating selection specific to application • Crack systems form when flaw size & stress reach threshold • Coatings minimize contact damage induced during: – Handling, packaging, shipping – Device manufacturing – In-service use • Coating optimized for specific device & fabrication processes – Material & thickness selected for anticipated conditions – Full-width and partial-width coatings enable different device designs – Mechanical properties dominated by glass Coated Substrate Cross-Section Science & Technology

Open the catalog to page 8

Convey Flexible Glass with Roller Systems Requires managing bend stress during device fabrication • Flexible glass is flexible –Do not handle as rigid substrate – Stiffness of 50µm glass 120µm PEN – Control stresses through roller handling system – Approach compatible with sheet-fed or roll-to-roll systems Conveyance in CAMM ECD Tool Al Sputtering in CAMM General Vac System Un-wind Re-wind Science & Technology Deposition drum

Open the catalog to page 9

Flexible Glass is Compatible with R2R Processing Demonstrated continuous ITO patterning ITO Deposition Development & Etch Supply Roll Take-Up Roll Cooling Drum Supply Roll Science & Technology Take-Up Roll

Open the catalog to page 10

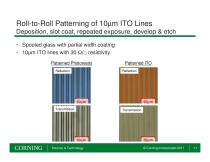

Roll-to-Roll Patterning of 10µm ITO Lines Deposition, slot coat, repeated exposure, develop & etch • Spooled glass with partial width coating • 10µm ITO lines with 30 Ω resistivity Patterned Photoresist Reflection

Open the catalog to page 11

Summary • Flexible glass offers advantages for device designs, materials & processes – Includes dimensional & thermal stability and hermeticity – Enables high performance active devices • Glass mechanical reliability understood – Form high initial strength & minimize defects – Manage stresses with appropriate conveyance – Optimized solutions are application specific • Flexible glass is compatible with continuous processing – Demonstrated patterning of 10µm ITO lines – Process optimizations possible to take advantage of glass capabilities Science & Technology

Open the catalog to page 12

Acknowledgements • Corning – Scott Glaesemann – Don Clark – Jill VanDewoestine – Michael Sorensen • CAMM – Mark Poliks Science & Technology

Open the catalog to page 13All CORNING Display Technologies catalogs and technical brochures

-

Gorilla® Glass 5

2 Pages

-

Corning Iris®

2 Pages

-

Aspheres by Corning

2 Pages

-

UltraFlat™

2 Pages

-

Tropel® FlatMaster® MSP

2 Pages

-

Optical Solutions

4 Pages

-

EAGLE XG® Slim

2 Pages

-

Scoring of AMLCD Glass

4 Pages

Archived catalogs

-

Jade® Product Information Sheet

3 Pages

-

Jade® Material Information Sheet

2 Pages