Catalog excerpts

Flexible glass for device substrate and hermetic barrier applications S. Garner, G. Merz, G.S. Glaesemann, J. Lin, L. Tian, E. Park, S. Logunov, X. Li September 19, 2012

Open the catalog to page 1

• Flexible glass • Mechanical reliability • Glass encapsulation compatibility • Summary

Open the catalog to page 2

Flexible Electronics Applications Continuing to Emerge Significant advances occurring in device designs and processes • “Flexible electronics” devices typically focused on thin, light, or conformal • Device applications include: – Display (e-paper, color filter, OLED, LCD) – Touch sensor – Photovoltaic – Lighting • Processes include: high-resolution and high-registration patterning and printing • Glass substrate opportunities progressing toward flexible sheets and web Flexible Glass Sheets

Open the catalog to page 3

Flexible Glass Enables High-Quality Electronics Substrate choice critical for device fabrication & performance • Substrate integrates designs, materials, & processes – Essential for overall optimization – Glass enables improved resolution, registration, performance & lifetime • Corning® WillowTM Glass compatible with sheet-fed and R2R processes – Thickness 200 m – Alkali-free borosilicate composition – Optimized for device substrate and hermetic barrier applications Flexible glass barrier Flexible glass substrate © Corning Incorporated 2012

Open the catalog to page 4

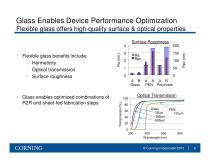

Glass Enables Device Performance Optimization Flexible glass offers high-quality surface & optical properties Surface Roughness 3 2 • Glass enables optimized combinations of R2R and sheet-fed fabrication steps • Flexible glass benefits include: – Hermeticity – Optical transmission – Surface roughness Optical Transmission Glass - 50 m - 100 m - 600 m

Open the catalog to page 5

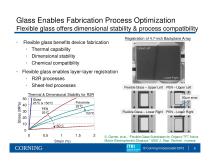

Glass Enables Fabrication Process Optimization Flexible glass offers dimensional stability & process compatibility Registration of 4.7-inch Backplane Array Flexible glass benefits device fabrication • Thermal capability • Dimensional stability • Chemical compatibility • Flexible glass enables layer-layer registration • R2R processes • Sheet-fed processes Flexible Glass – Upper Left Thermal & Dimensional Stability for R2R Stress (MPa) Flexible Glass – Lower Right S. Garner, et al., “Flexible Glass Substrates for Organic TFT Active Matrix Electrophoretic Displays,” IEEE J. Disp. Technol., in...

Open the catalog to page 6

Flexible Glass Enables Thin, Light, Conformal Displays Capability demonstrated with 100 m glass substrates Active Matrix Segmented Color LCD, 4” diag., <170 m thick, qVGA S. Hoehla, et al., “Active Matrix Color-LCD on 75 m Thick Flexible Glass Substrates,” IEEE J. Disp. Technol., vol. 8, pp. 309-316, 2012. EPD, 4.7” diag., <270 m thick, 170dpi P-Y. Lo, et al., “Flexible Glass Substrates for Organic TFT Active Matrix Electrophoretic Displays,” SID 2011. Color ChLCD, 5” diag., <210 m thick, 80ppi Color EKD, 3.5” diag., 3-layer stacked, <0.7mm K-W. Wu, et al., “Color ChLC E-paper Display with...

Open the catalog to page 7

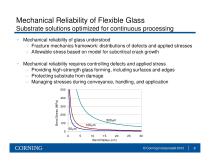

Mechanical Reliability of Flexible Glass Substrate solutions optimized for continuous processing • Mechanical reliability of glass understood – Fracture mechanics framework: distributions of defects and applied stresses – Allowable stress based on model for subcritical crack growth • Mechanical reliability requires controlling defects and applied stress – Providing high-strength glass forming, including surfaces and edges – Protecting substrate from damage – Managing stresses during conveyance, handling, and application 500

Open the catalog to page 8

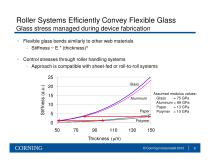

Roller Systems Efficiently Convey Flexible Glass Glass stress managed during device fabrication • Flexible glass bends similarly to other web materials – Stiffness ~ E * (thickness)3 • Control stresses through roller handling systems – Approach is compatible with sheet-fed or roll-to-roll systems Assumed modulus values: Glass = 75 GPa Aluminum = 69 GPa Paper = 13 GPa Polymer = 10 GPa m) Thickness (um) © Corning Incorporated 2012

Open the catalog to page 9

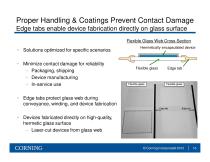

Proper Handling & Coatings Prevent Contact Damage Edge tabs enable device fabrication directly on glass surface Flexible Glass Web Cross-Section • Solutions optimized for specific scenarios • Minimize contact damage for reliability – Packaging, shipping – Device manufacturing – In-service use Hermetically encapsulated device Flexible glass • Edge tabs protect glass web during conveyance, winding, and device fabrication • Devices fabricated directly on high-quality, hermetic glass surface – Laser-cut devices from glass web

Open the catalog to page 10

Glass Surface Strength is Independent of Thickness New test methods developed for flexible substrates 99 90 Failure Probability (%) Failure Probability, % Strength, (MPa) Strength M Pa G.S. Glaesemann, et al., “The Strength of Thin Fusion Drawn Glass Sheets,” 11th ESG Conference 2012, Maastricht, The Netherlands

Open the catalog to page 11

Flexible Glass Reliability Enables Device Fabrication Reliability based on managing stress & defect distributions Flexible Glass Mechanical Reliability Flexible Glass Roller Conveyance

Open the catalog to page 12

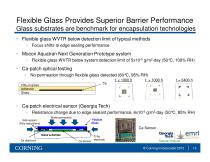

Flexible Glass Provides Superior Barrier Performance Glass substrates are benchmark for encapsulation technologies • Flexible glass WVTR below detection limit of typical methods – Focus shifts to edge sealing performance • Mocon Aquatran Next Generation Prototype system – Flexible glass WVTR below system detection limit of 5x10-5 g/m2-day (50°C, 100% RH) • Ca-patch optical testing • No permeation through flexible glass detected (60°C, 95% RH) Ca 100 m glass Adhesive Glass • Ca-patch electrical sensor (Georgia Tech) – Resistance change due to edge sealant performance, 6x10-5 g/m2-day (50°C,...

Open the catalog to page 13

Flexible Glass Enables Overall Device Optimization Glass is compatible with existing encapsulation methods • Flexible glass enables hermetic encapsulation of conformal devices OLED device with 5cm radius Barrier Thin metal cathode ETL HBL EML EBL HTL Metal anode WillowTM Glass M.Toerker, et al., “Transparent OLEDs for signage and decorative lighting applications,” LOPE-C 2012, Munich, June 20, 2012. • Specific encapsulation method selected to meet overall device requirements – Flexible glass compatibility demonstrated with typical encapsulation methods Vacuum Deposition Coating / Lamination...

Open the catalog to page 14All CORNING Display Technologies catalogs and technical brochures

-

Gorilla® Glass 5

2 Pages

-

Corning Iris®

2 Pages

-

Aspheres by Corning

2 Pages

-

UltraFlat™

2 Pages

-

Tropel® FlatMaster® MSP

2 Pages

-

Optical Solutions

4 Pages

-

EAGLE XG® Slim

2 Pages

-

Scoring of AMLCD Glass

4 Pages

Archived catalogs

-

Jade® Product Information Sheet

3 Pages

-

Jade® Material Information Sheet

2 Pages