Catalog excerpts

CO2 Laser Free-Shape Cutting of Flexible Glass Substrates Xinghua Li, Sean Garner September 25, 2012

Open the catalog to page 1

• Flexible Glass Substrates • CO2 Laser Free-shape Cutting • Summary Corning Willow Glass

Open the catalog to page 2

Flexible Glass Applications Continuing to Emerge Significant advances occurring in device designs and processes • Device applications include: – Display (e-paper, color filter, OLED, LCD) – Touch sensor – Photovoltaic – Lighting • Processes include: high-resolution and high-registration patterning and printing • “Flexible electronics” devices typically focused on thin, light, or conformal • Glass substrate opportunities progressing toward flexible sheets and web Flexible Glass Sheets

Open the catalog to page 3

Flexible Glass Enables High-Quality Electronics Substrate choice critical for device fabrication & performance • Substrate integrates designs, materials, & processes – Essential for overall optimization – Glass enables improved resolution, registration, performance & lifetime • Corning Willow Glass compatible with sheet-fed and R2R processes – Thickness 200 m – Alkali-free borosilicate composition – Optimized for device substrate and hermetic barrier applications Flexible glass barrier Flexible glass substrate © 2012 Corning Incorporated

Open the catalog to page 4

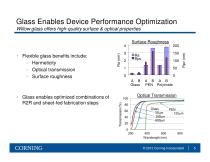

Glass Enables Device Performance Optimization Willow glass offers high-quality surface & optical properties Surface Roughness 3 2 • Glass enables optimized combinations of R2R and sheet-fed fabrication steps • Flexible glass benefits include: – Hermeticity – Optical transmission – Surface roughness Optical Transmission Glass - 50 m - 100 m - 600 m

Open the catalog to page 5

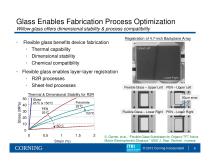

Glass Enables Fabrication Process Optimization Willow glass offers dimensional stability & process compatibility Registration of 4.7-inch Backplane Array Flexible glass benefits device fabrication • Thermal capability • Dimensional stability • Chemical compatibility • Flexible glass enables layer-layer registration • R2R processes • Sheet-fed processes Flexible Glass – Upper Left Thermal & Dimensional Stability for R2R Stress (MPa) Flexible Glass – Lower Right S. Garner, et al., “Flexible Glass Substrates for Organic TFT Active Matrix Electrophoretic Displays,” IEEE J. Disp. Technol., in...

Open the catalog to page 6

Willow Glass Enables Thin, Light, Conformal Displays Capability demonstrated with 100 m glass substrates Active Matrix Segmented Color LCD, 4” diag., <170 m thick, qVGA S. Hoehla, et al., “Active Matrix Color-LCD on 75 m Thick Flexible Glass Substrates,” IEEE J. Disp. Technol., vol. 8, pp. 309-316, 2012. EPD, 4.7” diag., <270 m thick, 170dpi P-Y. Lo, et al., “Flexible Glass Substrates for Organic TFT Active Matrix Electrophoretic Displays,” SID 2011. Color ChLCD, 5” diag., <210 m thick, 80ppi Color EKD, 3.5” diag., 3-layer stacked, <0.7mm K-W. Wu, et al., “Color ChLC E-paper Display with...

Open the catalog to page 7

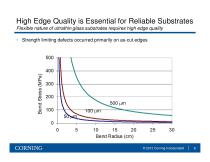

High Edge Quality is Essential for Reliable Substrates Flexible nature of ultrathin glass substrates requires high edge quality • Strength limiting defects occurred primarily on as-cut edges

Open the catalog to page 8

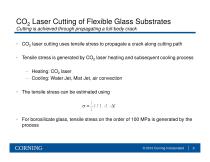

CO2 Laser Cutting of Flexible Glass Substrates Cutting is achieved through propagating a full-body crack • CO2 laser cutting uses tensile stress to propagate a crack along cutting path • Tensile stress is generated by CO2 laser heating and subsequent cooling process – Heating: CO2 laser – Cooling: Water Jet, Mist Jet, air convection • The tensile stress can be estimated using • For borosilicate glass, tensile stress on the order of 100 MPa is generated by the process

Open the catalog to page 9

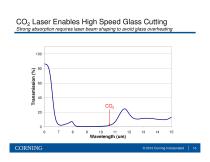

CO2 Laser Enables High Speed Glass Cutting Strong absorption requires laser beam shaping to avoid glass overheating Wavelength (um) © 2012 Corning Incorporated

Open the catalog to page 10

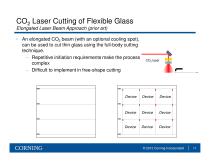

CO2 Laser Cutting of Flexible Glass Elongated Laser Beam Approach (prior art) • An elongated CO2 beam (with an optional cooling spot), can be used to cut thin glass using the full-body cutting technique. – Repetitive initiation requirements make the process complex – Difficult to implement in free-shape cutting

Open the catalog to page 11

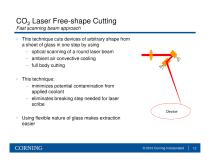

CO2 Laser Free-shape Cutting Fast scanning beam approach • This technique cuts devices of arbitrary shape from a sheet of glass in one step by using – optical scanning of a round laser beam – ambient air convective cooling – full body cutting • This technique: – minimizes potential contamination from applied coolant – eliminates breaking step needed for laser scribe Device • Using flexible nature of glass makes extraction easier

Open the catalog to page 12

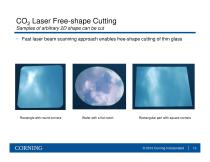

CO2 Laser Free-shape Cutting Samples of arbitrary 2D shape can be cut • Fast laser beam scanning approach enables free-shape cutting of thin glass Rectangle with round corners Wafer with a flat notch Rectangular part with square corners

Open the catalog to page 13

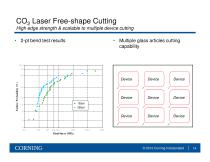

CO2 Laser Free-shape Cutting High edge strength & scalable to multiple device cutting • 2-pt bend test results • Multiple glass articles cutting capability

Open the catalog to page 14

Summary • CO2 laser free-shape cutting is capable of producing glass articles with arbitrary 2D shapes • CO2 laser cutting produces glass articles with high edge quality at high speed

Open the catalog to page 15All CORNING Display Technologies catalogs and technical brochures

-

Gorilla® Glass 5

2 Pages

-

Corning Iris®

2 Pages

-

Aspheres by Corning

2 Pages

-

UltraFlat™

2 Pages

-

Tropel® FlatMaster® MSP

2 Pages

-

Optical Solutions

4 Pages

-

EAGLE XG® Slim

2 Pages

-

Scoring of AMLCD Glass

4 Pages

Archived catalogs

-

Jade® Product Information Sheet

3 Pages

-

Jade® Material Information Sheet

2 Pages