Catalog excerpts

CORNELL PUMP COMPANY

Open the catalog to page 1

Cornell's two- and three-port enclosed, non-clog impellers are designed to handle large solids and maintain exceptional hydraulic efficiencies. Cornell's Delta-style impeller is specifically designed for handling stringy materials and heavy sludge for low- to medium-head applications and our three- or four-vane, semi-open impeller generates a cutting action designed to handle concentrated slurries for high head applications. SOLIDS HANDLING PUMPS ENCLOSED IMPELLER Cornell solids handling pumps are used for waste water, sludge, stringy material, de-watering, abrasive transfer, canneries,...

Open the catalog to page 2

INDUSTRIAL CHOPPER PUMPS With its heavy-duty, ASTM A536 grade 65-45-12 ductile iron construction, using our patented Cycloseal® design (patent #5489187), the Cornell Chopper pump is ideally suited for chopping solids. The replaceable cutter bar is made of T1 tool steel, heat treated to a minimum 60 Rockwell C hardness. Heat treated impellers of cast alloy steel, AISI 8630, and 416 stainless steel shaft sleeves are standard. The bearing frame is fitted with heavy-duty back-to-back angular contact ball bearings to handle axial loads and provide exceptional bearing life. Our Chopper pumps are...

Open the catalog to page 3

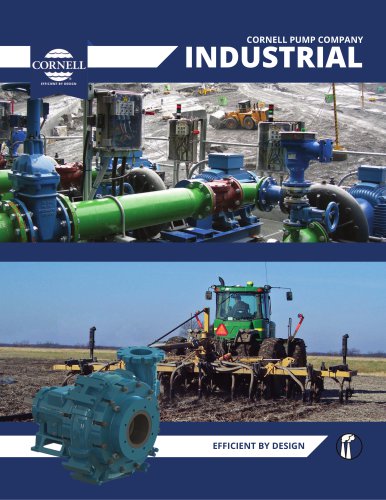

INDUSTRIAL PROCESS Cornell offers a comprehensive line of standard and special purpose industrial process centrifugal pumps including 1” to 30” discharge diameters. We offer premium quality centrifugal pumps that incorporate highly engineered features specifically designed to enhance performance and longevity. CLEAR LIQUID PUMPS Cornell Clear Liquid Pumps are used for commercial and residential irrigation, golf course and lawn maintenance, aqua culture, fountains, breweries, laundries cooling towers, fire fighting, reverse osmosis feed, and water boosters. The W, Y, R and H series pumps are...

Open the catalog to page 4

INDUSTRIAL PROCESS ENERGY EFFICIENCY Cornell pumps are designed to deliver best-in-class efficiency. Depending on operating hours, fuelant, and horsepower required, you can save $3,000 per year (or more) in energy costs. Cornell Pump manufactures more than 60 clear liquid and nonclog pumps that meet or exceed optimum efficiency standards for centrifugal pumps. EXTERNAL HYDRAULIC BALANCE LINE Cornell’s external hydraulic balance line equalizes pressure between the impeller hub area and the pump suction to reduce axial loading acting on the impeller, shaft and bearings. The balance line also...

Open the catalog to page 5

CONSTRUCTION Cornell’s dry priming (as opposed to wet priming) is the best solution available to address the self-priming needs of the construction and de-watering industries. Cornell Pump has built its worldwide reputation on quality and reliability. Our Redi-Prime® pumps are engineered and manufactured to provide ultra-reliable, trouble-free operation. Hydraulic efficiencies typically exceed 80% – significantly higher than what is provided by our competition. Moreover, Cornell’s automatic priming and re-priming is achieved with a 50 SCFM diaphragm vacuum pump. Cornell’s priming system was...

Open the catalog to page 6

REDI-PRIME® PUMP OPTIONS: SOLIDS HANDLING PUMPS MODEL DISCHARGE SIZE PUMP OPTIONS: SOLIDS HANDLING PUMPS MODEL DISCHARGE SIZE

Open the catalog to page 7

REFRIGERATION & COOLING QUALITY ASSURANCE Cornell Pump proudly maintains its ISO 9001:2008 certification that validates Cornell is in compliance with all necessary processes to meet customer requirements. The elements associated with ISO 9001:2008 certification include such areas as contract review, design and development, production, purchasing, quality control and service. Cornell liquid over-feed and transfer pumps are designed and manufactured specifically for industrial refrigeration applications such as cold storage, food processing, ice chiller, and turbine inlet cooling. With...

Open the catalog to page 8

FOOD PROCESS HYDRO-TRANSPORT FOOD HANDLING Cornell Pump engineers understand the important role food handling pumps play in today’s marketplace. Cornell’s innovative single-port impeller configuration with an offset volute provides the end user with a food handling pump capable of transporting even the most delicate/difficult food products such as cherries, lettuce, potatoes, or carrots. Cornell’s unique single port impeller reduces product damage and ensures product integrity. The single port impeller is a proven feature consisting of a large and rounded leading vane edge designed...

Open the catalog to page 9

ENERGY RECOVERY COMMITMENT TO EXCELLENCE Cornell Pump employees share the commitment to meet the requirements of our customers. We will provide services, parts, and products that satisfy all the agreed-upon requirements. We shall strive for a working environment of continual improvement by keeping the following priorities in mind: 1. Achieve total satisfaction on the basis of team effort. 2. Do the job right the first time to achieve consistent, on-time performance. 3. Put quality first. If all requirements have not been met, we will never knowingly complete a service, transaction, or ship...

Open the catalog to page 10

FOOD PROCESS MOUNTING CONFIGURATIONS Cornell’s modular frame design allows for easy adaptability. Choose a pump, then pick the mounting configuration best suited to your application. Right-hand and left-hand rotation along with tangential or centerline discharges are available for most pumps. CC Horizontal Close Coupled RUN-DRY™ OPTION The Cycloseal is a self-contained single mechanical seal upgrade for the standardized food grade packing feature. It requires no external flushing which is ideal for eliminating the water usage normally associated with mechanical seals. The Cycloseal uses...

Open the catalog to page 11

MARKET AND PRODUCT LINE CORNELL PUMP COMPANY CORNELL PUMP COMPANY CORNELL PUMP COMPANY FOOD PROCESS FOOD PROCESS CORNELL PUMP COMPANY END GUN BOOSTER PUMP CORNELL PUMP COMPANY CORNELL PUMP COMPANY CUTTER PUMPS CORNELL PUMP COMPANY CORNELL PUMP COMPANY CORNELL PUMP COMPANY HYDRO TURBINE HYDRAULIC SUBS CORNELL PUMP COMPANY MINE DEWATERING CORNELL PUMP COMPANY CORNELL PUMP COMPANY CORNELL PUMP COMPANY CORNELL PUMP COMPANY CORNELL PUMP COMPANY MANURE PUMPS MINING PUMPS DESIGNED FOR COARSE ABRASIVES FOR CENTER PIVOT IRRIGATION STANDARD SPECIFICATIONS • Models Available - 4NNT, 6NNT, 8NNT, etc. •...

Open the catalog to page 12All Cornell Pump catalogs and technical brochures

-

CO-PILOT

4 Pages

-

CHOPPER PUMP

4 Pages

-

High Flow Low Head Pumps

4 Pages

-

Water Transfer Brochure

8 Pages

-

Run-Dry brochure

4 Pages

-

CD4MCu

4 Pages

-

SUBMERSIBLES

2 Pages

-

STX SERIES

8 Pages

-

SLURRY CURVES

12 Pages

-

SLURRY PUMPS

8 Pages

-

REPLACEMENT PARTS

1 Pages

-

REDI-PRIME®

8 Pages

-

MX SERIES

8 Pages

-

MP SERIES

8 Pages

-

IMMERSIBLE MOTORS

2 Pages

-

HYDRAULIC SUBMERSIBLES

4 Pages

-

EDGE END GUN BOOSTER

4 Pages

-

CYCLOSEAL

8 Pages

-

CUTTER PUMP

8 Pages

-

CD4CMu

4 Pages

-

WATER TRANSFER

8 Pages

-

REFRIGERATION

8 Pages

-

OIL and GAS

8 Pages

-

MX MINING SERIES

8 Pages

-

MUNICIPAL

8 Pages

-

MINING BROCHURE

8 Pages

-

MANURE PUMP BROCHURE

8 Pages

-

FOOD PROCESS BROCHURE

8 Pages

-

AGRICULTURE BROCHURE

8 Pages

Archived catalogs

-

Industrial Brochure

8 Pages