Catalog excerpts

Xenus XTL ™ Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Fax: 781-828-6547 Tech Support: E-mail: sales@copleycontrols.com, Internet: http://www.copleycontrols.com Page 1 of 30 RoHS DIGITAL SERVO DRIVE for BRUSHLESS/BRUSH MOTORS descriptio n Xenus combines CANopen networking with 100% digital control of brushless or brush motors in an off-line powered package that can operate from single or three-phase mains with continuous power output to 4 kW. Standard models use quad A/B digital encoders for feedback. Two other versions are available for use with resolvers or sin/cos analog encoders. Xenus operates as a Motion Control Device under the DSP-402 protocol of the CANopen DS-301 V4.01 (EN 50325-4) application layer. DSP-402 modes supported include: Profile Position, Profile Velocity, Profile Torque, Interpolated Position (PVT), and Homing. Drive commissioning is fast and simple using CME 2 software operating under Windows® communicating with Xenus via CAN or an RS-232 link. CAN address selection is by a 16-position rotary switch on the front panel. If there are more than fifteen devices on a CAN bus, the additional address bits needed can come from programmable inputs, or can be set in flash memory. Profile Position Mode does a complete motion index on command with S-curve acceleration & deceleration, top speed, and distance programmable. In PVT mode, the controller sends out a sequence of points each of which is an increment of a larger, more complex move than a single index or profile. The drive then uses cubic polynomial interpolation to “connect the dots” such that the motor reaches each point (Position) at the specified velocity (Velocity) at the prescribed time (Time). Homing mode is configurable to work with a variety of limit, index, and home switches such that the drive moves the motor into a position that has an absolute reference to some part of the machine. Eleven logic inputs are programmable as limit or home switches, stepper/encoder pulse inputs, reset, digital torque or velocity reference, or motor over-temperature. A twelfth input is dedicated to the drive Enable function. Three programmable logic outputs are for reporting a drive fault or other status indications. A fourth optically-isolated output can drive a motor brake from the external +24 Vdc power supply or can be programmed as a logic output. In addition to CANopen motion commands, Xenus can operate as a stand-alone drive. Current and velocity modes accept ±10 Vdc analog, digital 50% PWM or PWM/polarity inputs. In position mode inputs can be incremental position commands from step-motor controllers in Pulse/Direction or CW/CCW format, ±10 Vdc analog, or A/B quadrature commands from a master-encoder. Pulse to position ratio is programmable for electronic gearing. Power output of the drive varies with the input power which can range from 100 to 240 Vac, and from 47 to 63 Hz. Either single or three phase mains can be used giving Xenus the ability to work in the widest possible range of industrial settings. Signal and control circuits are isolated from the high-voltage power supply and inverter stage that connect to the mains. A +24 Vdc input powers control circuits for keep-alive operation permitting the drive power stage to be completely powered down without losing position information or communications with the control system. Control Modes • Indexer, Point-to-Point, PVT • Camming, Gearing, Position, Velocity, Torque Command Interface • Stepper commands Single-ended or Differential selectable • CANopen/DeviceNet • ASCII and discrete I/O • ±10V position/velocity/torque command • PWM velocity/torque command • Master encoder (Gearing/Camming) Communications • CANopen/DeviceNet • RS232 Feedback • Digital quad A/B encoder • Analog sin/cos encoder (-S versions) • Resolver (-R versions) • Secondary encoder / emulated encoder out • Digital Halls I/O - Digital • 12 inputs, 4 outputs Accessories • External regen resistors • External edge filter Dimensions: mm [in] • 7.5 x 5.5 x 2.5 [191 x 140 x 64] Model Vac Ic Ip XTL-230-18 100 - 240 6 18 XTL-230-36 100 - 240 12 36 XTL-230-40 100 - 240 20 40 Add -S to part numbers above for sin/cos feedback, or add -R for resolver feedback models.

Open the catalog to page 1

Xenus XTL ™ DIGITAL SERVO DRIVE for BRUSHLESS/BRUSH MOTORS Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Fax: 781-828-6547 Tech Support: E-mail: sales@copleycontrols.com, Internet: http://www.copleycontrols.com Page 2 of 30 RoHS GENERAL SPECIFICATIONS Test conditions: Wye connected load: 2 mH line-line. Ambient temperature = 25 °C. Power input = 230 Vac, 60 Hz, 1 Ø MODEL XTL-230-18 XTL-230-36 XTL-230-40 Same specs for -S and -R models Output CURRENT Peak Current 18 (12.7) 36 (25.5) 40 (28.3) Adc (Arms, sinusoidal) Peak time 1 1 1 s Continuous current (Note 1) 6...

Open the catalog to page 2

Xenus XTL™ Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Fax: 781-828-6547 Tech Support: E-mail: sales@copleycontrols.com, Internet: http://www.copleycontrols.com Page 3 of 30 RoHS DIGITAL SERVO DRIVE for BRUSHLESS/BRUSH MOTORS e ncoder Digitaligital quadquad a/b Encoder Type Quadrature, differential line driver outputs Signals A, /A, B, /B, (X, /X, index signals optional) Frequency 5 MHz line frequency, 20 MHz quadrature count frequency Analogalog Encoder Type Sin/cos, differential line driver outputs, 0.5 Vpeak-peak (1.0 Vpeak-peak differential) centered about 2.5...

Open the catalog to page 3

REGEN+REGEN-REGEN+REGEN-3.00 (76,2)1.5 (38,1)7.15 (181,6)5.54 (140,7)2.55 (64,8)1.99 (50,5)0.925 (23,5)STANDARDHEATSINK OPTION (-HS)6.75(171,5)LOW-PROFILEHEATSINK OPTION (-HL)0.88 (22,4)1.00 (25,4)8 x 0.1607.55 (191,7)(4,1) Chassis Grounding: For CE compliance and machine safety use external tooth lockwashers between mounting screw head and drive heatplate. Recommended screws are #6-32 (M3.5) torqued to 8~10 lb·in (0.79~1.02 N·m). Xenus XTL™ DIGITAL SERVO DRIVE for BRUSHLESS/BRUSH MOTORS Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Fax: 781-828-6547 Tech Support:...

Open the catalog to page 4All Copley Controls catalogs and technical brochures

-

XenusPLUS Compact EtherCAT XEC

30 Pages

-

XenusPLUS Compact CANopen XPC

30 Pages

-

Control Networks

8 Pages

-

R-Series Guide

8 Pages

-

Selection Guide

24 Pages

-

Xenus R10

30 Pages

-

Accelnet R23

24 Pages

-

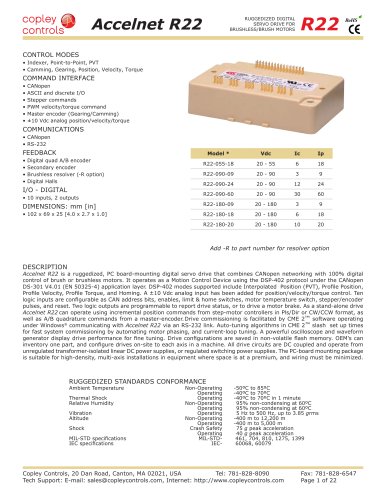

Accelnet R22

22 Pages

-

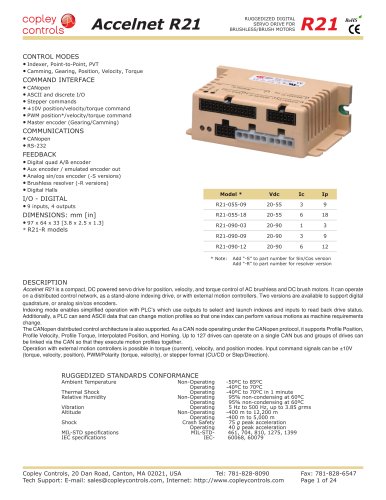

Accelnet R21

24 Pages

-

Accelnet R20

24 Pages

-

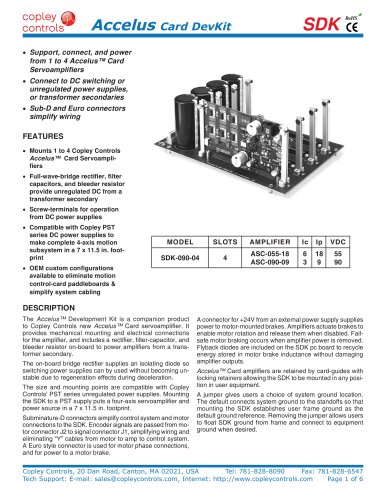

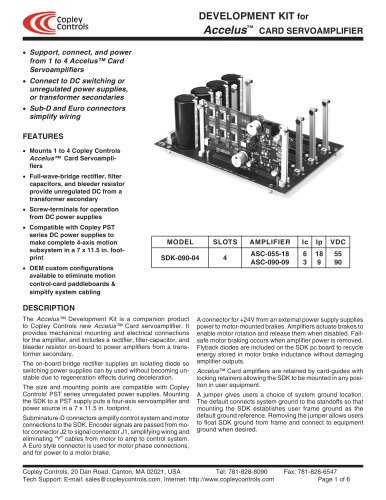

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

ASP-X2 Accelus Panel Dual

10 Pages

-

Junus

10 Pages

-

CAN-PCI-02

2 Pages

-

CAN-IPM-01

8 Pages

-

Bantam

18 Pages

-

Bantam R30

18 Pages

-

503

6 Pages

-

Power Supply Subsystem

8 Pages

-

Shunt Regulator

2 Pages

-

Xenus PLUS 2-Axis CANopen

34 Pages

-

Xenus RoHS PLUS CANopen

28 Pages

-

Xenus PLUS 2-Axis EtherCAT

34 Pages

-

Xenus PLUS EtherCAT

28 Pages

-

Xenus Edge Filter

16 Pages

-

Regen Resistors

24 Pages

-

Xenus Micro

24 Pages

-

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

Accelus Panel

10 Pages

-

Accelnet Plus EtherCAT Panel

18 Pages

-

Accelnet Micro Module and Kit

24 Pages

-

Accelnet Micro Panel

24 Pages

-

Accelnet Module Development Kit

8 Pages

-

Accelnet Module

14 Pages

-

Accelnet Panel ADP

24 Pages