Catalog excerpts

Xenus PLUS 2-Axis CANopen XP2 RoHS 2-AXIS DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS Control Modes • Profile Position-Velocity-Torque, Interpolated Position, Homing • Camming, Gearing • Indexer Command Interface • CANopen • ASCII and discrete I/O • Stepper commands • ±10V position/velocity/torque • PWM velocity/torque command • Master encoder (Gearing/Camming) Communications • CANopen DS-402 • RS-232 Accessories • External regen resistors Feedback Incremental Encoders • Digital quad A/B Analog Sin/Cos Panasonic Incremental A Format • Aux. quad A/B encoder / encoder out Absolute Encoders • SSI, EnDat, Absolute A, Tamagawa & Panasonic Absolute A Sanyo Denki Absolute A, Biss Resolver (-R option) • Brushless Resolver Other • Digital Halls Safe Torque Off (STO) • SIL 3, Category 4, PL e I/O Digital • 22 inputs, 7 outputs • 2 High-speed, non-isolated outputs I/O Analog • 2, 14-bit inputs Dimensions: in [mm] • 9.24 [234.7] x 5.77 [146.6] x 2.31 [58.7] Model Vac Ic Ip XP2-230-20 100~240 10 20 Current ratings are for each axis Add -R for resolver feedback option DESCRIPTION XP2 set new levels of performance, connectivity, and flexibility. CANopen communications provides a widely used cost-effective industrial bus. A wide range of absolute encoders are supported. High resolution A/D converters ensure optimal current loop performance. Both isolated and high-speed non-isolated I/O are provided. For safety critical applications, redundant power stage enable inputs (STO) can be employed. Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Tech Support: E-mail: sales@copleycontrols.com, Web: http://www.copleycontrols.com Fax: 781-828-6547 Page 1 of 34

Open the catalog to page 1

Xenus PLUS 2-Axis CANopen XP2 RoHS GENERAL SPECIFICATIONS Test conditions: Wye connected load: 2 mH line-line. Ambient temperature = 25° C. Power input = 230 Vac, 60 Hz, 1 Ø MODEL XP2-230-20 OUTPUT CURRENT (EACH AXIS) Peak Current 20 (14) Adc (Arms, sinusoidal) Peak time 1 s Continuous current (Heatsink required) 10 (7) Adc (Arms, sinusoidal) INPUT POWER Mains voltage, phase, frequency 100~240 Vac, ±10%, 1 Ø or 3 Ø, 47~63 Hz Maximum Mains Current, 1Ø (Note 2) 20 Arms Maximum Mains current, 3Ø (Note 2) 15.4 Arms +24 Vdc Control power +20 to +32 Vdc, 0.5~1.1 Adc (Note 3) Required for...

Open the catalog to page 2

1. Heatsinking and/or forced-air cooling is required for continuous output power rating. Order XP2-230-20 with -H option for factory-installed heatsink, or order XP2-HK for user-installed kit. 3. With no encoders connected the minimum current requirement for the +24V supply is 500 mA With four encoders operating at the maximum 400 mA rating of the four +5V supplies the +24 current requirement is ~1.1 Adc Cut-in Voltage Drop-Out Voltage Internal solid-state switch drives external regen resistor (see Ordering Guide for types) + HV > 390 Vdc Regen output is on, (optional external) regen...

Open the catalog to page 3

Xenus PLUS 2-Axis CANopen XP2 RoHS FEEDBACK SPECIFICATIONS FEEDBACK Incremental: Digital Incremental Encoder Quadrature signals, (A, /A, B, /B, X, /X), differential (X, /X Index signals not required) 5 MHz maximum line frequency (20 M counts/sec) MAX3097 differential line receiver with 121 Ω terminating resistor between complementary inputs Analog Incremental Encoder Sin/cos format (sin+, sin-, cos+, cos-), differential, 1 Vpeak-peak, ServoTube motor compatible, BW > 300 kHz, 121 Ω terminating resistor between complementary inputs Analog Index signal Differential, 121 Ω terminating resistor...

Open the catalog to page 4

Xenus PLUS 2-Axis CANopen XP2 RoHS CANOPEN CONNECTORS Dual RJ-45 connectors that accept standard Ethernet cables are provided for CAN bus connectivity. Pins are wired-through so that drives can be daisy-chained and controlled with a single connection to the user’s CAN interface. A CAN terminator should be placed in the last drive in the chain. The XTL-NK connector kit provides a D-Sub adapter that plugs into a CAN controller and has an RJ-45 socket that accepts the Ethernet cable. CANOPEN Based on the CAN V2.0b physical layer, a robust, two-wire communication bus originally designed for...

Open the catalog to page 5

Xenus PLUS 2-Axis CANopen XP2 RoHS COMMUNICATIONS AMP LEDS Bi-color LEDs on J7 give the state of each axis of the Xenus drive. Colors do not alternate, and can be solid ON or blinking: Green/Solid = Drive OK and enabled. Will run in response to reference inputs or CANopen commands. Green/Slow-Blinking = Drive OK but NOT-enabled. Will run when enabled. Green/Fast-Blinking = Positive or Negative limit switch active. Drive will only move in direction not inhibited by limit switch. Red/Solid = Transient fault condition. Drive will resume operation when fault is removed. Red/Blinking = Latching...

Open the catalog to page 6

Xenus PLUS XP2 2-Axis CANopen RoHS SAFE TORQUE OFF (STO) DESCRIPTION The XP2 provides the Safe Torque Off (STO) function as defined in IEC 61800-5-2. Three opto-couplers are provided which, when de-energized, prevent the upper and lower devices in the PWM outputs from being operated by the digital control core. This provides a positive OFF capability that cannot be overridden by the control firmware, or associated hardware components. When the opto-couplers are activated (current is flowing in the input diodes), the control core will be able to control the on/off state of the PWM outputs....

Open the catalog to page 7

Xenus PLUS 2-Axis CANopen XP2 RoHS COMMAND INPUTS DIGITAL POSITION Digital position commands can be in either single-ended or differential format. Single-ended signals should be sourced from devices with active pull-up and pull-down to take advantage of the high-speed inputs. Differential inputs have 121 Ω line-terminators. SINGLE-ENDED PULSE & DIRECTION IN4(14) DIFFERENTIAL PULSE & DIRECTION IN2(12) Pulse PULSE+ IN3(13) IN5(15) PULSE- Direction COMMAND SINGLE-ENDED IN4(14) DIRECTION+ Axis A Axis B Pls, Enc A 10 15 Dir, Enc B SINGLE-ENDED CU/CD Signal DIRECTION- IN5(15) 11 30 DIFFERENTIAL...

Open the catalog to page 8All Copley Controls catalogs and technical brochures

-

XenusPLUS Compact EtherCAT XEC

30 Pages

-

XenusPLUS Compact CANopen XPC

30 Pages

-

Control Networks

8 Pages

-

R-Series Guide

8 Pages

-

Selection Guide

24 Pages

-

Xenus R10

30 Pages

-

Accelnet R23

24 Pages

-

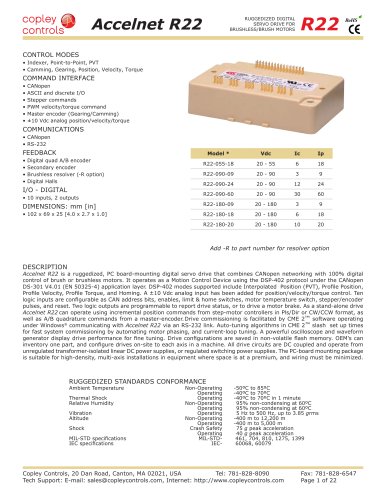

Accelnet R22

22 Pages

-

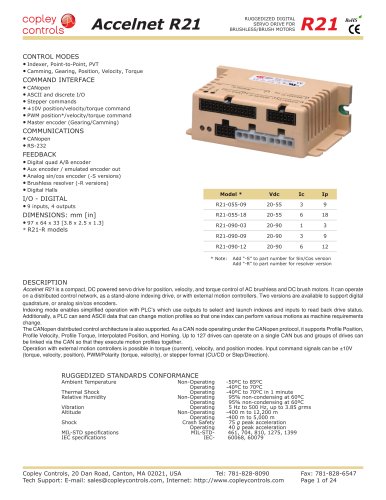

Accelnet R21

24 Pages

-

Accelnet R20

24 Pages

-

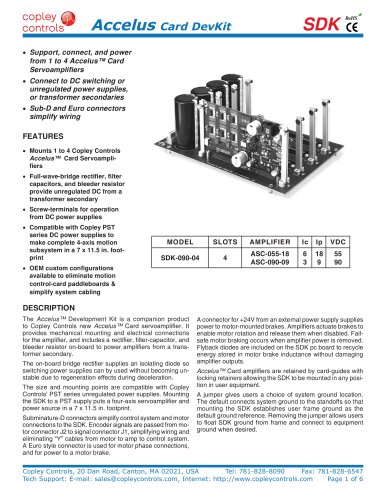

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

ASP-X2 Accelus Panel Dual

10 Pages

-

Junus

10 Pages

-

CAN-PCI-02

2 Pages

-

CAN-IPM-01

8 Pages

-

Bantam

18 Pages

-

Bantam R30

18 Pages

-

503

6 Pages

-

Power Supply Subsystem

8 Pages

-

Shunt Regulator

2 Pages

-

Xenus RoHS PLUS CANopen

28 Pages

-

Xenus PLUS 2-Axis EtherCAT

34 Pages

-

Xenus PLUS EtherCAT

28 Pages

-

Xenus Edge Filter

16 Pages

-

Regen Resistors

24 Pages

-

Xenus Micro

24 Pages

-

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

Accelus Panel

10 Pages

-

Xenus XTL

30 Pages

-

Accelnet Plus EtherCAT Panel

18 Pages

-

Accelnet Micro Module and Kit

24 Pages

-

Accelnet Micro Panel

24 Pages

-

Accelnet Module Development Kit

8 Pages

-

Accelnet Module

14 Pages

-

Accelnet Panel ADP

24 Pages