Catalog excerpts

Control Modes 4-axis DIGITAL DRIVE for stepper MOTORS • Position (Microstepping) • Position/Velocity/Torque (Servo Mode) • Indexer, Point-to-Point, PVT • Camming, Gearing Command Interface • CANopen • ASCII and discrete I/O • Stepper commands • Master encoder (Gearing/Camming) Feedback • Digital quad A/B/X encoder I/O Digital • 24 HS inputs • 8 MOSFET outputs I/O SPI • 1 HS input • 4 HS outputs Dimensions: mm [in] • 101.6 x 76.2 x 20.83 [4.00 x 3.00 x 0.83] description Stepnet SP4 is a four-axis, high-performance, DC powered drive for position, An SPI port is provided with one high-speed input and four high-speed digital and velocity control of stepper motors via CANopen. Using advanced FPGA outputs. If not used for SPI, the input and outputs are programmable for technology, the SP4 provides a significant reduction in the cost per node in other functions. multi-axis CANopen systems. An RS-232 serial port provides a connection to Copley’s CME2 software Each of the four axes in the SP4 operate as CANopen nodes under DSP-402 for commissioning, firmware upgrading, and saving configurations to flash for motion control devices. Supported modes include: Profile Position-Velocity, memory. The CANopen port is optically isolated. Interpolated Position Mode (PVT), and Homing. Drive power is transformer-isolated DC from regulated or unregulated power Servo mode allows position/velocity/torque control. Servo mode allows supplies. An AuxHV input is provided for “keep-alive” operation permitting CANopen or digital PWM control of position/velocity/torque. In microstepping the drive power stage to be completely powered down without losing position mode stepper command pulses and master encoder for camming or gearing information, or communications with the control system. is supported. Twenty-four high-speed digital inputs with programmable functions are provided. There are eight mosfet outputs that are 24V compatible. Copley Controls, 20 Dan Road, Canton, MA 02021, USA P/N 16-01544 Rev 00

Open the catalog to page 1

GENERAL SPECIFICATIONS Test conditions: Load = Bipolar stepper: 2 mH + 2 Ω per phase. Ambient temperature = 25°C, +HV = HVmax MODEL Output Power (each axis) Peak Current Peak time Continuous current Maximum Output Voltage Adc (Arms-sine), ±5% Sec Adc (Arms-sine) per phase (Note 1) INPUT POWER (module) HVmin~HVmax +14 to +55 Ipeak 12 Icont 12 Aux HV +14 to +55 Vdc , 6 W max with all four PWM OUTPUTS Type PWM ripple frequency Vdc Transformer-isolated Adc (1 sec) peak Adc continuous (Note 1) encoders powered, 3 W max with no encoders Dual H-bridge MOSFET , 12.5 kHz center-weighted PWM,...

Open the catalog to page 2

Stepnet motor connections (per axis) Phases A, /A, B, /B Digital Incremental Encoder Encoder power PWM outputs to 2-phase, 4-wire bipolar stepper motors Quadrature signals, (A, B, X), using inputs [IN26~37] 2 MHz maximum line frequency (8 M counts/sec) when driven by active devices (See DC POWER OUTPUTS section) protections HV Overvoltage +HV > 55 Vdc Drive outputs turn off until +HV < 55 Vdc HV Undervoltage +HV < +14 Vdc Drive outputs turn off until +HV > +14 Vdc Drive over temperature Heat plate > 90°C. Drive outputs turn off Short circuits Output to output, output to ground, internal PWM...

Open the catalog to page 3

CME 2 SOFTWARE Drive setup is fast and easy using CME 2 software. All of the operations needed to configure the drive are accessible through this powerful and intuitive program. Auto-phasing of brushless motor Hall sensors and phase wires eliminates “wire and try”. Connections are made once and CME 2 does the rest thereafter. Encoder wire swapping to establish the direction of positive motion is eliminated. Motor data can be saved as .CCM files. Drive data is saved as .CCX files that contain all drive settings plus motor data. This eases system management as files can be cross-referenced to...

Open the catalog to page 4

CANopeN Based on the CAN V2.0b physical layer, a robust, two-wire communication bus originally designed for automotive use where low-cost and noise-immunity are essential, CANopen adds support for motion-control devices and command synchronization. The result is a highly effective combination of data-rate and low cost for multi-axis motion control systems. Device synchronization enables multiple axes to coordinate moves as if they were driven from a single control card. CANopen communication Stepnet uses the CAN physical layer signals CANH, CANL, and GND for connection, and CANopen protocol...

Open the catalog to page 5

Input/output digital INPUTS SP4 has 24 high-speed digital inputs, all of which have programmable functions. They are compatible with 5V logic and have 100 ns R/C filters when driven by devices with active pull-up/pull-down outputs. high-speed digital INPUTs +5 VDC max Programmable functions of the digital inputs include: • Drive Enable • Positive Limit switch • Negative Limit switch • Digital Command Inputs • Home switch • Drive Reset • Motion abort signals & pins The pins in the chart are on connector P3. The functions shown are the defaults. These can be programmed for other functions....

Open the catalog to page 6

DIGITAL COMMAND INPUTS Digital commands are single-ended format and should be sourced from devices with active pull-up and pull-down to take advantage of the high-speed inputs. The active edge (rising or falling) is programmable for the Pulse/Dir and CU/CD formats. how it looks in cme2 CME2 -> Basic Setup -> Operating Mode Options DIGITAL POSITION pulse & Direction Axis A,B,C,D Axis Controller Pulse how it looks in cme2 CME2 -> Basic Setup -> Operating Mode Options CU/CD (PUlse up / pulse down) Axis A,B,C,D Axis Controller CU (Count-Up) This screen shows the configuration screen for Pulse &...

Open the catalog to page 7

DIGITAL COMMAND INPUTS (cont’d) how it looks in cme2 CME2 -> Basic Setup -> Operating Mode Options DIGITAL TORQUE, VELOCITY PWM command (100% Duty cycle) Axis Controller Axis A,B,C,D CME2 -> Main Page-> PWM Command pwm command (50% duty cycle) Axis Controller Axis A,B,C,D This screen shows the 50% Duty Cycle selection. Other modes are selectable via radio buttons and pull-down menus for Operating Mode and Command Source. signals & pins The pins in the chart are on connector P3 Axis A Note: 1) The functions shown for [IN5~6], [IN11~12], [IN17~18] and [IN23~24] apply when they are used as...

Open the catalog to page 8All Copley Controls catalogs and technical brochures

-

XenusPLUS Compact EtherCAT XEC

30 Pages

-

XenusPLUS Compact CANopen XPC

30 Pages

-

Control Networks

8 Pages

-

R-Series Guide

8 Pages

-

Selection Guide

24 Pages

-

Xenus R10

30 Pages

-

Accelnet R23

24 Pages

-

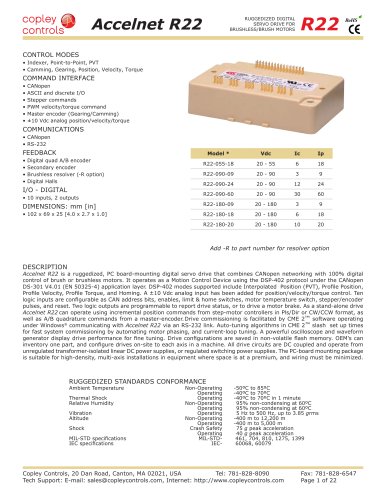

Accelnet R22

22 Pages

-

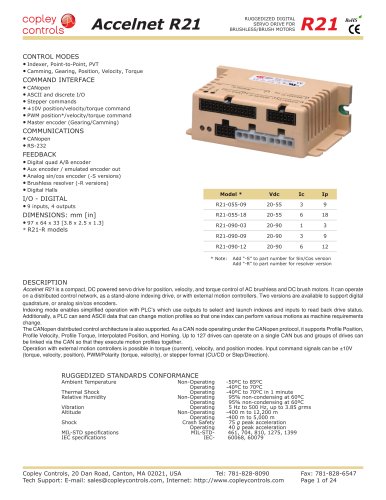

Accelnet R21

24 Pages

-

Accelnet R20

24 Pages

-

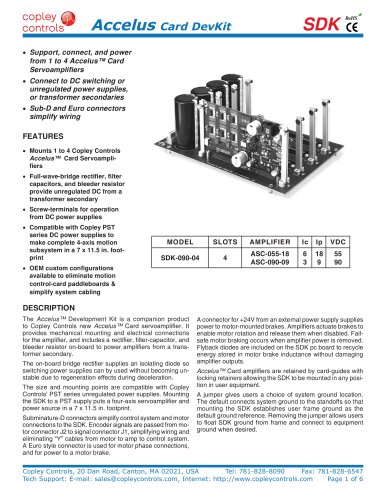

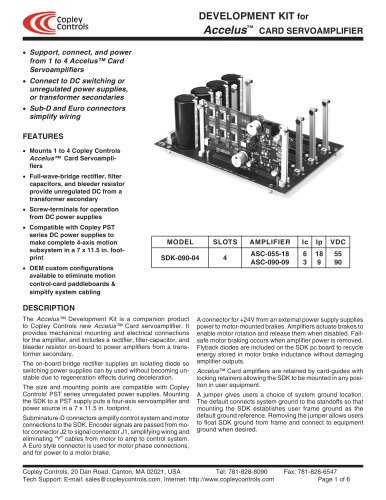

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

ASP-X2 Accelus Panel Dual

10 Pages

-

Junus

10 Pages

-

CAN-PCI-02

2 Pages

-

CAN-IPM-01

8 Pages

-

Bantam

18 Pages

-

Bantam R30

18 Pages

-

503

6 Pages

-

Power Supply Subsystem

8 Pages

-

Shunt Regulator

2 Pages

-

Xenus PLUS 2-Axis CANopen

34 Pages

-

Xenus RoHS PLUS CANopen

28 Pages

-

Xenus PLUS 2-Axis EtherCAT

34 Pages

-

Xenus PLUS EtherCAT

28 Pages

-

Xenus Edge Filter

16 Pages

-

Regen Resistors

24 Pages

-

Xenus Micro

24 Pages

-

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

Accelus Panel

10 Pages

-

Xenus XTL

30 Pages

-

Accelnet Plus EtherCAT Panel

18 Pages

-

Accelnet Micro Module and Kit

24 Pages

-

Accelnet Micro Panel

24 Pages

-

Accelnet Module Development Kit

8 Pages

-

Accelnet Module

14 Pages

-

Accelnet Panel ADP

24 Pages