Catalog excerpts

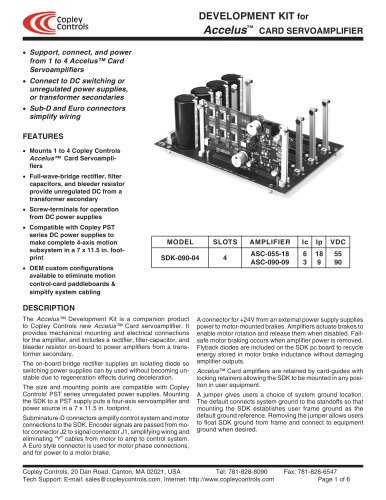

Accelus Card ASC DIGITAL SERVOAMPLIFIER for BRUSHLESS/BRUSH MOTORS RoHS • PCB Mount • Position, Velocity, and Torque Control • Controller Interface Stepper Interface ±10V Velocity / Torque Command PWM Velocity / Torque Command Electronic gearing • Field-Oriented Control for Optimal Speed / Torque • Auto-Tuning and Auto-Phasing • Feedback Digital Encoder and Halls description The Accelus™ servoamplifier drives DC brushless motors in position, velocity, or torque modes with 100% digital control. Commutation is sinusoidal using encoder feedback from the motor. Hall signals are used for phase-initialization and phase-correction eliminating motor hunting after power-up. Advanced field-oriented-control ensures the highest motor torque over a wide speed range, minimizing motor heating and maximizing efficiency. Digital control algorithms transform AC stator currents into direct and quadrature components. The torque-producing quadrature current is controlled by the current loop, and the direct component is driven to zero eliminating losses from current that doesn’t produce torque. Space-vector modulation produces higher speeds than sine-pwm modulation from the same buss voltage. CME 2™ software communicates with Accelus through an RS-232 link for complete amplifier setup. Auto-phasing and auto-tuning algorithms in CME 2™ slash set up times for fast system commissioning and eliminate “re-wire and try” so common in brushless motor installations. CME 2™ automates current loop tuning, as well as motor, Hall, and encoder phasing. A powerful oscilloscope and signal generator display amplifier performance for fine tuning thereafter. Amplifier control parameters are saved in non-volatile flash Model Ic Ip Vdc ASC-055-18 6 18 55 ASC-090-09 • Programmable I/O: 6 inputs, 2 outputs 3 9 90 memory. OEM’s can inventory one part, and configure amplifiers on-site to each axis in a machine. Accelus™ works with motion controllers that close positionloops using incremental encoder feedback and process the position error in a PID filter to produce an amplifier command for torque, force, or velocity. Only one +/-10V analog, or a one or two-wire digital PWM/(DIR) control signal is required. All commutation is done in the amplifier. In position-mode, Accelus™ accepts two-wire digital stepmotor control signals (CW/CCW, or Count/Direction), or operates as a slave from a master encoder. The ratio between input position pulses and motor position is programmable. Velocity control is derived from motor encoder signals. Velocity mode is useful not only for speed-setpoint applications, but enables operation with PLC’s or controllers that output position-error signals with no PID filtering. All amplifier circuits are DC coupled and operate from unregulated transformer-isolated DC power supplies, or regulated switching power supplies. The package is a single board with no heatplate. Solderless mating connectors on pc boards mount Accelus™ at 0° or 90°. Installation and replacement is fast and doesn’t damage amplifier connections. A Development Kit is available that mounts 1~4 Accelus™ amplifiers and provides unregulated DC power from an isolation step-down transformer. Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Tech Support: E-mail: sales@copleycontrols.com, Web: http://www.copleycontrols.com Fax: 781-828-6547 Page 1 of 8

Open the catalog to page 1

Accelus Card DIGITAL SERVOAMPLIFIER for BRUSHLESS/BRUSH MOTORS ASC RoHS GENERAL SPECIFICATIONS Test conditions: Load = 1mH in series with 1 Ohm. Ambient temperature = 25 deg. C. MODEL OUTPUT POWER Peak Current Peak time Continuous current INPUT POWER HVmin~HVmax PWM OUTPUTS Type PWM ripple frequency COMMUTATION & CONTROL Current loop update rate Commutation Phase Initialization ASC-055-18 ASC-090-09 18 (12.73) 1 6 (4.24) 9 (6.36) 1 3 (2.12) Amps DC (Amps ACrms) Sec Amps DC (Amps ACrms) 20~90 10 3.3 VDC, Transformer-isolated ADC (1 sec) peak input current ADC continuous current 20~55 20 6.7...

Open the catalog to page 2

Accelus COMMUNICATION Accelus™ is configured via a three-wire, full-duplex RS-232 port that operates from 9600 to 115,200 Baud. CME 2™ provides a graphic user interface (GUI) to set up all of Accelus features via a computer serial port. Connections to the Accelus™ RS-232 port P1 are via an RJ-11 style connector, and through the pc board connector J1 (J1-19 & 20). RxD, TxD, and Gnd signals comprise the signals supported. The Accelus™ Serial Cable Kit contains a modular cable, and an adapter that connects to a 9-pin, Sub-D serial port connector (COM1, COM2, etc.) on PC’s and compatibles....

Open the catalog to page 3

Accelus Card DIGITAL SERVOAMPLIFIER for BRUSHLESS/BRUSH MOTORS DIGITAL REFERENCE INPUTS (CONT’D) For torque or velocity control, the inputs may be configured in two formats: 1. PWM (0~100%) & Polarity 2. PWM (50%) In the first case, the PWM signal can vary from 0% to 100%, and the Polarity signal is a DC level that controls the direction of the motor. The PWM duty-cycle controls the amplifier output current, or motor velocity. In current mode, 100% corresponds to the maximum output current. In velocity mode, it commands the maximum velocity that is configured. Another type of PWM input is...

Open the catalog to page 4

Accelus the phase conductors near to each other to maximize transmission-line effects, and to reduce noise coupling into adjacent circuitry. Motor cabling should use twisted, shielded conductors for best shielding and to minimize PWM noise coupling into other circuits. The motor cable shield should connect to motor frame and the amplifier high-current ground terminal (HV return) for best results. Card DIGITAL SERVOAMPLIFIER for BRUSHLESS/BRUSH MOTORS supplies in user equipment. These power supplies should also connect to the HV Return at a single point. The final configuration should embody...

Open the catalog to page 5

Accelus DIGITAL SERVOAMPLIFIER Card for BRUSHLESS/BRUSH MOTORS ASC RoHS AMPLIFIER CONNECTIONS 25 DAC Analog Torque or Velocity Reference Input ±10V Ref(+) Input 26 Encoder /A Neg Enable [IN4] 18 Signal Gnd 24 Signal Gnd Controller Digital I/O 15 TxD Controller RS-232 RxD I/O RxD TxD 9 2 Gnd 5 3 5 3 5 D-Sub 9-pos Female 6 Yellow 3 Hall W Fault Output [OUT2] 3 Red 2 Black V P1 6 +24V 5 1 3 5 2 4 6 Motor V 7 9 11 8 10 12 Motor U 13 15 17 14 16 Fuse 18 W Gnd 3 2 BRAKE 13 Motor W TxD HALLS W 4 /Brake Output [OUT1] Fuse V MOTOR RxD RJ-11 Modular Cable U Mount external capacitor <= 12" (30 cm)...

Open the catalog to page 6All Copley Controls catalogs and technical brochures

-

XenusPLUS Compact EtherCAT XEC

30 Pages

-

XenusPLUS Compact CANopen XPC

30 Pages

-

Control Networks

8 Pages

-

R-Series Guide

8 Pages

-

Selection Guide

24 Pages

-

Xenus R10

30 Pages

-

Accelnet R23

24 Pages

-

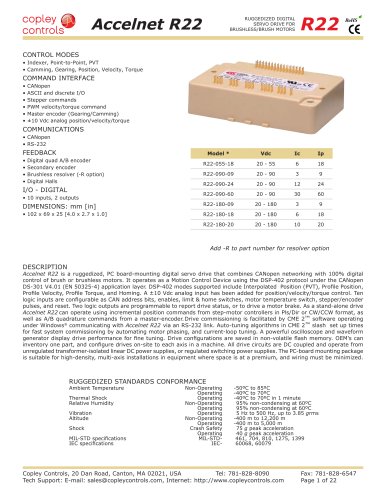

Accelnet R22

22 Pages

-

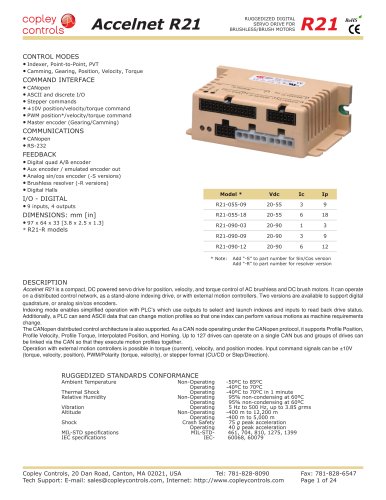

Accelnet R21

24 Pages

-

Accelnet R20

24 Pages

-

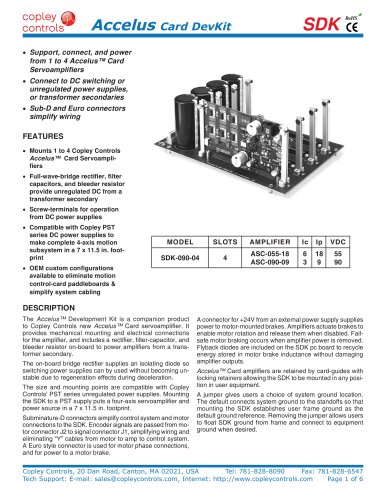

Accelus Card Development Kit

6 Pages

-

ASP-X2 Accelus Panel Dual

10 Pages

-

Junus

10 Pages

-

CAN-PCI-02

2 Pages

-

CAN-IPM-01

8 Pages

-

Bantam

18 Pages

-

Bantam R30

18 Pages

-

503

6 Pages

-

Power Supply Subsystem

8 Pages

-

Shunt Regulator

2 Pages

-

Xenus PLUS 2-Axis CANopen

34 Pages

-

Xenus RoHS PLUS CANopen

28 Pages

-

Xenus PLUS 2-Axis EtherCAT

34 Pages

-

Xenus PLUS EtherCAT

28 Pages

-

Xenus Edge Filter

16 Pages

-

Regen Resistors

24 Pages

-

Xenus Micro

24 Pages

-

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

Accelus Panel

10 Pages

-

Xenus XTL

30 Pages

-

Accelnet Plus EtherCAT Panel

18 Pages

-

Accelnet Micro Module and Kit

24 Pages

-

Accelnet Micro Panel

24 Pages

-

Accelnet Module Development Kit

8 Pages

-

Accelnet Module

14 Pages

-

Accelnet Panel ADP

24 Pages