Catalog excerpts

Micro Module EtherCAT DIGITAL SERVO DRIVE FOR BRUSH & BRUSHLESS MOTORS Control Modes • • • • • • Cyclic Synchronous Position-Velocity-Torque (CSP, CSV, CST) Cyclic Synchronous Torque with Commutation Angle (CSTCA) Profile Position-Velocity-Torque, Interpolated Position (PT,PVT), Homing Indexer, Point-to-Point, CPL Camming, Gearing Position, Velocity, Torque Command Interface • • • • • CANopen application protocol over EtherCAT (CoE) ASCII, Serial Binary, and discrete I/O Stepper or Quad A/B position commands PWM Velocity/Torque command Master encoder (Gearing/Camming) • Dual Absolute Encoder Ports SSI EnDat 2.1, 2.2 Absolute A Tamagawa Absolute A Panasonic , Sanyo Denki Absolute A Format BiSS • Incremental Digital quad A/B/X encoder Analog Sin/Cos encoder • Other Digital Halls • 7 High-speed digital inputs • 6 High-speed digital outputs • 1 Differential analog input DESCRIPTION AEV sets new levels of performance, connectivity, and flexibility. CANopen application protocol over EtherCAT (CoE) communication provides a widely used cost-effective industrial bus. A wide range of absolute encoders are supported. Safe Torque Off (STO) eliminates external contactors and wiring, reducing system cost and complexity. For safety critical applications, redundant STO disable inputs can be employed. Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 P/N 16-01

Open the catalog to page 1

Micro Module EtherCAT GENERAL SPECIFICATIONS Test conditions: Load = Wye connected load: 1 mH + 1Ω line-line. Ambient temperature = 25 °C. +HV = HVmax MODEL OUTPUT POWER INPUT POWER HVmin to HVmax Ipeak Icont VLOGIC VLOGIC Power Type PWM ripple frequency Current loop, small signal HV Compensation Current loop update rate Position & Velocity loop update rate 2.5 kHz typical, bandwidth will vary with tuning & load inductance Changes in HV do not affect bandwidth 16 kHz (62.5 µs) 4 kHz (250 µs) COMMAND INPUTS EtherCAT: Stand-alone mode Digital position reference Digital torque & velocity...

Open the catalog to page 2

Micro Module EtherCAT GENERAL SPECIFICATIONS DC POWER OUTPUT 500 mA maximum. Protected for overload or shorts. Shared by dual encoders Function Standard Safety Integrity Level Inputs Type Input current (typical) Response time Muting PWM outputs are inactive and current to the motor will not be possible when the STO function is enabled Designed to IEC-61508-1, IEC-61508-2, IEC-61800-5-2, ISO-13849-1 SIL 3, Category 3, Performance level e 2 two-terminal: STO-IN1+,STO-IN1-, STO-IN2+, STO-IN2Opto-isolators, 5 V compatible, Vin-LO ≤ 2.0 Vdc or open, Vin-HI ≥ 3.3 Vdc STO-IN1, STO-IN2: 11 mA each...

Open the catalog to page 3

Micro Module EtherCAT GENERAL SPECIFICATIONS MOTOR CONNECTIONS Motor U,V,W Encoder Halls Motemp Drive outputs to 3-phase brushless motor, Wye or delta connected For DC brush motor use outputs U & V Minimum inductance: 200 µH line-line Digital encoders, incremental and absolute (see FEEDBACK below) Analog Sin/Cos incremental see Commutation (below) Inputs are programmable to disable the drive if motor sensor drives input HI or LO Incremental encoders Digital Incremental Encoder Analog Incremental Encoder Absolute encoders EnDat 2.1, 2.2, SSI Absolute A Format BiSS (B&C) Terminators...

Open the catalog to page 4

Micro Module EtherCAT ETHERCAT COMMUNICATIONS EtherCAT is the open, real-time Ethernet network developed by Beckhoff based on the widely used 100BASE-TX cabling system. EtherCAT enables high-speed control of multiple axes while maintaining tight synchronization of clocks in the nodes. Data protocol is CANopen application protocol over EtherCAT (CoE) based on CiA 402 for motion control devices. More information on EtherCAT can be found on this web-site: http://ethercat.org/default.htm User Mounting board RS-232 COMMUNICATIONS RS-232 PORT EZ Boards The serial port is a full-duplex, three-wire...

Open the catalog to page 5

Micro Module EtherCAT SAFE TORQUE OFF (STO) The Safe Torque Off (STO) function is defined in IEC 61800-5-2. Two channels are provided which, when de-energized, prevent the upper and lower devices in the PWM outputs from producing torque in the motor. This provides a positive OFF capability that cannot be overridden by the control firmware, or associated hardware components. When the opto-couplers are energized (current is flowing in the input diodes), the control core will be able to control the on/off state of the PWM outputs to produce torque in the motor. Refer to the 16-01687 Accelnet...

Open the catalog to page 6

Micro Module EtherCAT DIGITAL COMMAND INPUTS: POSITION STAND-ALONE MODE DIGITAL POSITION-CONTROL INPUTS AEV works with motion controllers that output pulses to command position. These formats are supported: Step/Direction Count-Up/Count-Down (CU/CD) A/B Quadrature Encoder In Step/Direction mode, a pulse-train controls motor position, and the direction is controlled by a DC level at the Direction input. CU/CD (Count-Up/Count-Down) signals command the motor to move CW or CCW depending on which input the pulse-train is directed to. The motor can also be operated in an electronic gearing mode...

Open the catalog to page 7

Micro Module EtherCAT MULTI-MODE PORT AS AN INPUT COMMAND INPUT POSITION COMMANDS: DIFFERENTIAL Command Options • Pulse & Direction • CW & CCW (Clockwise & Counter-Clockwise) • Encoder Quad A & B • Camming Encoder A & B input Pulse, CW, Quad Encoder A, Vel-Curr-Magnitude, Vel-Curr-50% /Pulse, /CW, Quad Encoder /A, /Vel-Curr-Magnitude, /Vel-Curr-50% Direction, CCW, Quad Encoder B, Vel-Curr-Direction /Direction, /CCW, Quad Encoder /B, /Vel-Curr-Direction Input/Output Select Pulse/Dir or CU/CD differential commands CURRENT or VELOCITY COMMANDS: DIFFERENTIAL • Current/Velocity Magnitude &...

Open the catalog to page 8

Micro Module EtherCAT MULTI-MODE PORT AS AN OUTPUT OUTPUT TYPES BUFFERED FEEDBACK OUTPUTS: DIFFERENTIAL An incremental encoder connected as primary feedback from the motor is internally connected to the multi-port configured as an output. This can then be wired to a motion controller that needs position data without the need for split-wiring cables from the encoder alone. • Encoder Quad A, B, X channels • Direct internal connection between quad A/B/X encoder feedback and differential line drivers for A/B/X outputs EMULATED FEEDBACK OUTPUTS: DIFFERENTIAL Firmware produces emulated quad A/B...

Open the catalog to page 9All Copley Controls catalogs and technical brochures

-

XenusPLUS Compact EtherCAT XEC

30 Pages

-

XenusPLUS Compact CANopen XPC

30 Pages

-

Control Networks

8 Pages

-

R-Series Guide

8 Pages

-

Selection Guide

24 Pages

-

Xenus R10

30 Pages

-

Accelnet R23

24 Pages

-

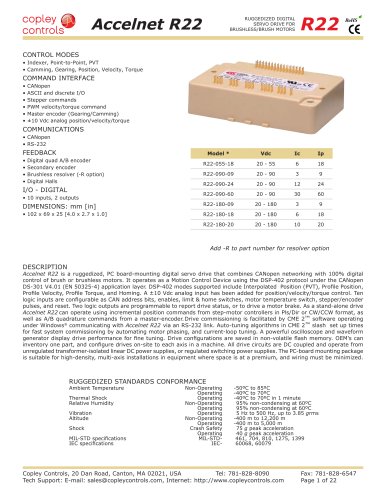

Accelnet R22

22 Pages

-

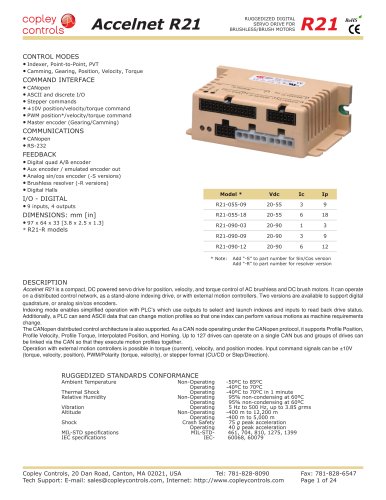

Accelnet R21

24 Pages

-

Accelnet R20

24 Pages

-

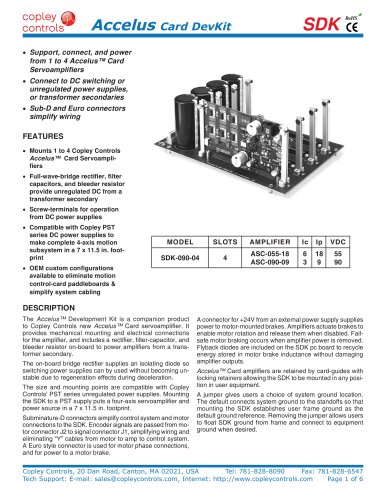

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

ASP-X2 Accelus Panel Dual

10 Pages

-

Junus

10 Pages

-

CAN-PCI-02

2 Pages

-

CAN-IPM-01

8 Pages

-

Bantam

18 Pages

-

Bantam R30

18 Pages

-

503

6 Pages

-

Power Supply Subsystem

8 Pages

-

Shunt Regulator

2 Pages

-

Xenus PLUS 2-Axis CANopen

34 Pages

-

Xenus RoHS PLUS CANopen

28 Pages

-

Xenus PLUS 2-Axis EtherCAT

34 Pages

-

Xenus PLUS EtherCAT

28 Pages

-

Xenus Edge Filter

16 Pages

-

Regen Resistors

24 Pages

-

Xenus Micro

24 Pages

-

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

Accelus Panel

10 Pages

-

Xenus XTL

30 Pages

-

Accelnet Plus EtherCAT Panel

18 Pages

-

Accelnet Micro Module and Kit

24 Pages

-

Accelnet Micro Panel

24 Pages

-

Accelnet Module Development Kit

8 Pages

-

Accelnet Module

14 Pages

-

Accelnet Panel ADP

24 Pages