Catalog excerpts

Accelnet R23 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R23 RoHS CONTROL MODES • Indexer, Point-to-Point, PVT • Camming, Gearing, Position, Velocity, Torque COMMAND INTERFACE • CANopen • ASCII and discrete I/O • Stepper commands • ±10V position/velocity/torque command • PWM velocity/torque command • Master encoder (Gearing/Camming) COMMUNICATIONS • CANopen • RS232 Model FEEDBACK Ic Ip Vdc 14~55 • Digital Quad A/B encoder • Secondary encoder • Digital Halls • Resolver (-R option) R23-055-06 3 6 R23-055-10 5 10 20~55 R23-090-04 2 4 14~90 I/O - DIGITAL R23-090-08 4 8 20~90 • 10 inputs, 3 outputs FOR RESOLVER OPTION, ADD “-R” TO THE PART NUMBER DIMENSIONS: mm [in] • 64 x 41 x 16 [2.5 x 1.6 x 0.6] DESCRIPTION Accelnet R23 is a digital servodrive that combines CANopen networking with 100% digital control of brush or brushless motors in a pc board mounting package. Accelnet R23 operates as a Motion Control Device using the DSP-402 protocol under the CANopen DS-301 V4.01 (EN 50325-4) application layer. DSP-402 modes supported include Interpolated Position (PVT), Profile Position, Profile Velocity, Profile Torque, and Homing. There are ten logic inputs. One is dedicated to the Amp Enable function, the other nine are programmable. There are three logic outputs rated to +30 Vdc. Used as a stand-alone drive, Accelnet R23 can operate using incremental position commands from step-motor controllers in Pulse/Direction or CU/CD format, as well as A/B quadrature commands from a masterencoder. Torque or velocity control can be from digital PWM signals, or analog ±10 V. Drive commissioning is facilitated by CME 2™ software operating under Windows® communicating with Accelnet R23 via CAN or an RS-232 link. Auto-tuning algorithms in CME 2™ slash set up times for fast system commissioning by automating motor phasing, and current-loop tuning. A powerful oscilloscope and waveform generator displays drive performance for fine tuning. Drive configurations are saved in non-volatile flash memory. OEM’s can inventory one part, and configure drives onsite to each axis in a machine. Space-vector modulation delivers higher motor speeds and lower motor power dissipation than conventional sine-pwm modulation. Carriercancellation modulation all but eliminates motor ripple current and dissipation at a standstill. Current-loop sampling is at 15 kHz, position and velocity loops at 3 kHz and PWM ripple at 30 kHz. All drive circuits are DC coupled and operate from unregulated transformer-isolated linear DC power supplies, or regulated switching power supplies. The pc-board mounting package is suitable for high-density, multi-axis installations in equipment where space is at a premium, and wiring must be minimized. RUGGEDIZED STANDARDS CONFORMANCE Ambient Temperature Thermal Shock Relative Humidity Vibration Altitude Shock MIL-STD specifications IEC specifications Non-Operating Operating Operating Non-Operating Operating Operating Non-Operating Operating Crash Safety Operating MIL-STD- IEC- -50ºC to 85ºC -40ºC to 70ºC -40ºC to 70ºC in 1 minute 95% non-condensing at 60ºC 95% non-condensing at 60ºC 5 Hz to 500 Hz, up to 3.85 grms -400 m to 12,200 m -400 m to 5,000 m 75 g peak acceleration 40 g peak acceleration 461, 704, 810, 1275, 1399 60068, 60079 Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Tech Support: E-mail: sales@copleycontrols.com, Internet: http://www.copleycontrols.com Fax: 781-828-6547 Page 1 of 24

Open the catalog to page 1

Accelnet R23 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R23 RoHS GENERAL SPECIFICATIONS Test conditions: Load = Wye connected load: 1 mH+ 1Ω line-line. Ambient temperature = 25 °C. +HV = HVmax MODEL R23-055-06 R23-055-10 R23-090-04 R23-090-08 OUTPUT POWER Peak Current Peak time Continuous current Peak Output Power Continuous Output Power INPUT POWER HVmin to HVmax Ipeak Icont Aux HV 6 (4.2) 1 3 (2.1) 0.33 0.15 10 (7.1) 1 5 (3.5) 0.50 0.18 +14 to +55 6.6 3.3 +14 to HVmax 2.5 W 4 (2.8) 1 2 (1.4) 0.36 0.18 8 (5.7) 1 4 (2.8) 0.72 0.36 Adc (Arms, sinusoidal) Sec Adc (Arms,...

Open the catalog to page 2

Accelnet R23 DC POWER OUTPUT +5 Vdc MOTOR CONNECTIONS Motor U,V,W Encoder (primary) Encoder (secondary) Halls Motemp PROTECTIONS HV Overvoltage HV Undervoltage Drive over temperature Short circuits I2T Current limiting Latching / Non-Latching MECHANICAL Size Weight Contaminants Environment Cooling RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R23 RoHS 250 mA maximum. Directly connects to drive internal circuits. L-C filter required to isolate drive and external circuits Drive outputs to 3-phase brushless motor, Wye or delta connected For DC brush motor use outputs U & V...

Open the catalog to page 3

Accelnet R23 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R23 RoHS CME 2™ SOFTWARE Drive setup is fast and easy using CME 2™ software. All of the operations needed to configure the drive are accessible through this powerful and intuitive program which communicates with the drive over CAN or an RS-232 link. Motor data can be saved as .ccm files. Drive data is saved as .ccx files that contain all drive settings plus motor data. This eases system management as files can be cross-referenced to ampifiers. Once a drive configuration has been completed systems can be replicated easily...

Open the catalog to page 4

Accelnet R23 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R23 RoHS STAND-ALONE MODE DIGITAL POSITION-CONTROL INPUTS Accelnet Micro Module works with motion controllers that output pulses to command position. These formats are supported: Step/Direction CU/CD A/B Quadrature Encoder In Step/Direction mode, a pulse-train controls motor position, and the direction is controlled by a DC level at the Direction input. CU/CD (Count-Up/Count-Down) signals command the motor to move CW or CCW depending on which input the pulse-train is directed to. The motor can also be operated in an...

Open the catalog to page 5All Copley Controls catalogs and technical brochures

-

XenusPLUS Compact EtherCAT XEC

30 Pages

-

XenusPLUS Compact CANopen XPC

30 Pages

-

Control Networks

8 Pages

-

R-Series Guide

8 Pages

-

Selection Guide

24 Pages

-

Xenus R10

30 Pages

-

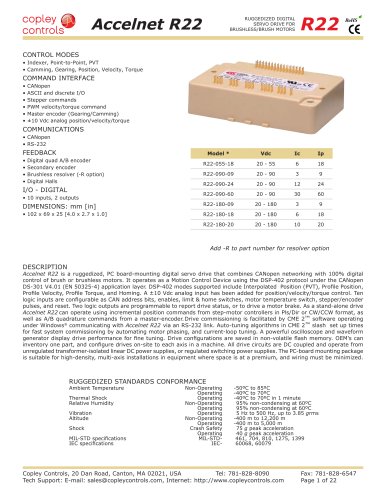

Accelnet R22

22 Pages

-

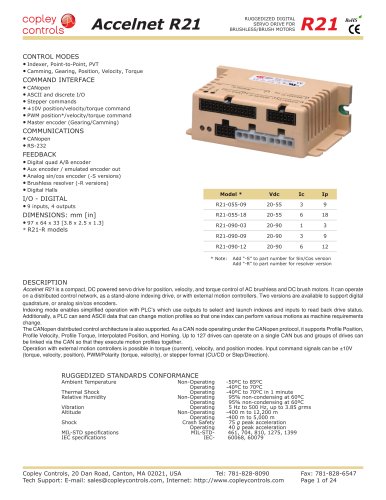

Accelnet R21

24 Pages

-

Accelnet R20

24 Pages

-

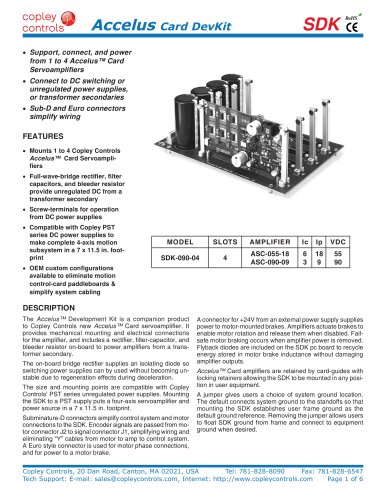

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

ASP-X2 Accelus Panel Dual

10 Pages

-

Junus

10 Pages

-

CAN-PCI-02

2 Pages

-

CAN-IPM-01

8 Pages

-

Bantam

18 Pages

-

Bantam R30

18 Pages

-

503

6 Pages

-

Power Supply Subsystem

8 Pages

-

Shunt Regulator

2 Pages

-

Xenus PLUS 2-Axis CANopen

34 Pages

-

Xenus RoHS PLUS CANopen

28 Pages

-

Xenus PLUS 2-Axis EtherCAT

34 Pages

-

Xenus PLUS EtherCAT

28 Pages

-

Xenus Edge Filter

16 Pages

-

Regen Resistors

24 Pages

-

Xenus Micro

24 Pages

-

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

Accelus Panel

10 Pages

-

Xenus XTL

30 Pages

-

Accelnet Plus EtherCAT Panel

18 Pages

-

Accelnet Micro Module and Kit

24 Pages

-

Accelnet Micro Panel

24 Pages

-

Accelnet Module Development Kit

8 Pages

-

Accelnet Module

14 Pages

-

Accelnet Panel ADP

24 Pages