Catalog excerpts

Accelnet R20 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R20 CONTROL MODES • Indexer, Point-to-Point, PVT • Camming, Gearing, Position, Velocity, Torque COMMAND INTERFACE • Stepper commands RoHS R Single-ended or Differential selectable • CANopen • ASCII and discrete I/O • ±10V position/velocity/torque command • PWM position/velocity/torque command • Master encoder (Gearing/Camming) COMMUNICATIONS • CANopen • RS-232 • RS-422 (Optional) FEEDBACK • Digital quad A/B encoder • Aux encoder / emulated encoder out • Analog sin/cos encoder (-S versions) • Brushless resolver (-R option) • Digital Halls I/O - DIGITAL • 12 inputs, 3 outputs DIMENSIONS: mm [in] • 168 x 99 x 31 [6.6 x 3.9 x 1.2] Model Ip Ic Vdc R20-055-18 18 6 55 R20-090-09 9 3 90 R20-090-18 18 6 90 R20-090-36 36 12 90 R20-180-09 9 3 180 R20-180-18 18 6 180 Add -S to part numbers above for sin/cos feedback Add -R to part numbers above for resolver feedback DESCRIPTION Accelnet R20 is a ruggedized high-performance, DC powered drive for position, velocity (using encoder, resolver, Halls, or BEMF), and torque control of brushless and brush motors. It operates as a distributed drive using the CANopen protocol, or as a stand-alone drive accepting analog or digital commands from an external motion controller. In stand-alone mode, current and velocity modes accept digital 50% PWM or PWM/polarity inputs as well as ±10V analog. In position mode inputs can be incremental position commands from step-motor controllers, analog ±10V, or A/B quadrature commands from a master-encoder. Pulse to position ratio is programmable for electronic gearing. Accelnet R20 models operate as Motion Control Devices under the DSP-402 protocol of the CANopen DS-301 V4.01 (EN 50325-4) application layer. DSP-402 modes supported include: Profile Position, Profile Velocity, Profile Torque, Interpolated Position Mode (PVT), and Homing. The two CAN ports are optically isolated from drive circuits. There are twelve digital inputs eleven of which have programmable functions. These include CAN address, motion-abort, limit & home switches, stepper/encoder pulse inputs, reset, digital torque or velocity reference, and motor over-temperature. Input [IN1] is dedicated for the drive Enable. There are three programmable logic outputs for reporting an drive fault, motor brake control, or other status indications. Drive power is transformer-isolated DC from regulated or unregulated power supplies. An AuxHV input powers control circuits for “keepalive” operation permitting the drive power stage to be completely powered down without losing position information, or communications with the control system. RUGGEDIZED STANDARDS CONFORMANCE Ambient Temperature Thermal Shock Relative Humidity Vibration Altitude Shock MIL-STD specifications IEC specifications Non-Operating Operating Operating Non-Operating Operating Operating Non-Operating Operating Crash Safety Operating MIL-STDIEC- -50ºC to 85ºC -40ºC to 70ºC -40ºC to 70ºC in 1 minute 95% non-condensing at 60ºC 95% non-condensing at 60ºC 5 Hz to 500 Hz, up to 3.85 grms -400 m to 12,200 m -400 m to 5,000 m 75 g peak acceleration 40 g peak acceleration 461, 704, 810, 1275, 1399 60068, 60079 Copley Controls, 20 Dan Road, Canton, MA 02021, USA Tel: 781-828-8090 Tech Support: E-mail: sales@copleycontrols.com, Internet: http://www.copleycontrols.com Fax: 781-828-6547 Page 1 of 24

Open the catalog to page 1

Accelnet R20 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R20 RoHS GENERAL SPECIFICATIONS Test conditions: Load = Wye connected load: 2 mH + 2 Ω line-line. Ambient temperature = 25°C, +HV = HVmax MODEL R20-055-18 R20-090-09 OUTPUT POWER R20-090-18 Peak Current 18 (12.7) 9 (6.4) 18 (12.7) Peak time 1 1 1 Continuous current 6 (4.2) 3 (2.1) 6 (4.2) Peak Output Power 0.92 0.79 1.55 Continuous “ “ 0.32 0.27 0.53 Output resistance 0.075 0.075 0.075 Maximum Output Voltage Vout = HV*0.97 - Rout*Iout INPUT POWER HVmin~HVmax Ipeak Icont Aux HV +20 to +55 20 6.7 PWM OUTPUTS Type PWM...

Open the catalog to page 2

Accelnet R20 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R20 RoHS FEEDBACK DIGITAL QUAD A/B ENCODER Type Signals Frequency Quadrature, differential line driver outputs A, /A, B, /B, (X, /X, index signals optional) 5 MHz line frequency, 20 MHz quadrature count frequency ANALOG ENCODER (-S OPTION) Type Sin/cos, differential line driver outputs, 0.5 Vpeak-peak (1.0 Vpeak-peak differential) centered about 2.5 Vdc typical. Common-mode voltage 0.25 to 3.75 Vdc Sin(+), sin(-), cos(+), cos(-) 230 kHz maximum line (cycle) frequency 10 bits/cycle (1024 counts/cycle) Signals Frequency...

Open the catalog to page 3

Accelnet R20 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R20 RoHS GENERAL SPECIFICATIONS (CONT’D) AGENCY STANDARDS CONFORMANCE EN 55011 : 1998 CISPR 11 (1997) Edition 2/Amendment 2: Limits and Methods of Measurement of Radio Disturbance Characteristics of Industrial, Scientific, and Medical (ISM) Radio Frequency Equipment EN 61000-6-1 : 2001 Electromagnetic Compatibility Generic Immunity Requirements Following the provisions of EC Directive 89/336/EEC: Safety Requirements for Electrical Equipment EN 61010-1 2nd Ed.: 2004 for Measurement, Control, and Laboratory use Following...

Open the catalog to page 4

Accelnet R20 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R20 RoHS COMMUNICATIONS CME 2 SOFTWARE Drive setup is fast and easy using CME 2 software communicating via RS-232 or over the CAN bus. All of the operations needed to configure the drive are accessible through this powerful and intuitive program. Autophasing of brushless motor Hall sensors and phase wires eliminates “wire and try”. Connections are made once and CME 2 does the rest thereafter. Encoder wire swapping to establish the direction of positive motion is eliminated. Motor data can be saved as .ccm files. Drive...

Open the catalog to page 5

Accelnet R20 RUGGEDIZED DIGITAL SERVO DRIVE FOR BRUSHLESS/BRUSH MOTORS R20 RoHS COMMUNICATIONS (CONTINUED) CANOPEN Based on the CAN V2.0b physical layer, a robust, two-wire communication bus originally designed for automotive use where low-cost and noise-immunity are essential, CANopen adds support for motion-control devices and command synchronization. The result is a highly effective combination of data-rate and low cost for multi-axis motion control systems. Device synchronization enables multiple axes to coordinate moves as if they were driven from a single control card. CANOPEN...

Open the catalog to page 6All Copley Controls catalogs and technical brochures

-

XenusPLUS Compact EtherCAT XEC

30 Pages

-

XenusPLUS Compact CANopen XPC

30 Pages

-

Control Networks

8 Pages

-

R-Series Guide

8 Pages

-

Selection Guide

24 Pages

-

Xenus R10

30 Pages

-

Accelnet R23

24 Pages

-

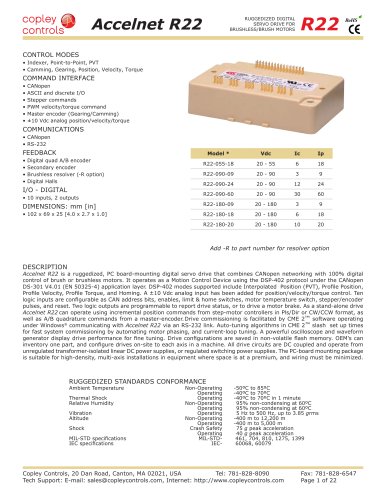

Accelnet R22

22 Pages

-

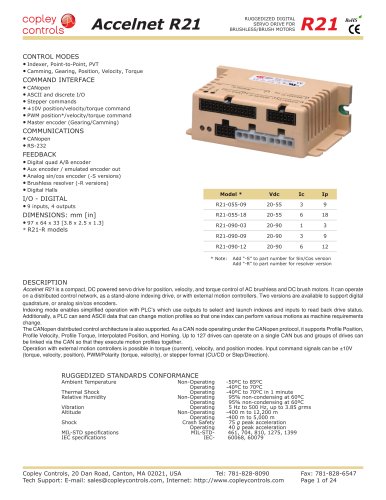

Accelnet R21

24 Pages

-

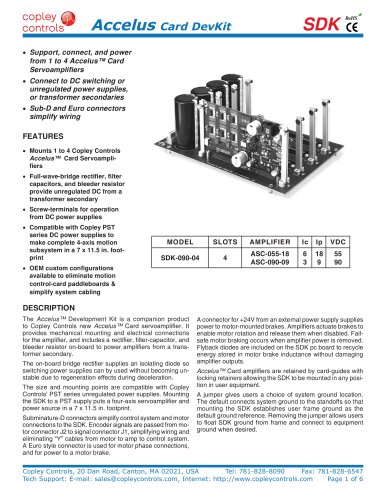

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

ASP-X2 Accelus Panel Dual

10 Pages

-

Junus

10 Pages

-

CAN-PCI-02

2 Pages

-

CAN-IPM-01

8 Pages

-

Bantam

18 Pages

-

Bantam R30

18 Pages

-

503

6 Pages

-

Power Supply Subsystem

8 Pages

-

Shunt Regulator

2 Pages

-

Xenus PLUS 2-Axis CANopen

34 Pages

-

Xenus RoHS PLUS CANopen

28 Pages

-

Xenus PLUS 2-Axis EtherCAT

34 Pages

-

Xenus PLUS EtherCAT

28 Pages

-

Xenus Edge Filter

16 Pages

-

Regen Resistors

24 Pages

-

Xenus Micro

24 Pages

-

Accelus Card Development Kit

6 Pages

-

Accelus Card

8 Pages

-

Accelus Panel

10 Pages

-

Xenus XTL

30 Pages

-

Accelnet Plus EtherCAT Panel

18 Pages

-

Accelnet Micro Module and Kit

24 Pages

-

Accelnet Micro Panel

24 Pages

-

Accelnet Module Development Kit

8 Pages

-

Accelnet Module

14 Pages

-

Accelnet Panel ADP

24 Pages