Catalog excerpts

1 Dosing equipment for aggressive gases Expandable and system adaptable (multipoint dosing) User can communicate with the CPU via control panel with display and keyboard or through the notebook or PC with SCADA software. Self-control and indication of faults Regulation cabinet can be expanded with : analogue input modules analogue output modules digital input modules, digital output modules motor modules Communication with PC and SCADA software AQUAprocessor series M 5700 C is unit built with main CPU (central processor unit) with TOUCH screen LCD display. The unit can be expanded through various other extension modules, as to the system. It is designed to control the process values on water plants, swimming pools, waste water plants or in industry. Regulation cabinet can be configured for manual or automatic output monitoring. The monitored data can be transmitted to a SCADA PC or other control system. Easy user-unit communication TOUCH screen LCD display Data history and digital communication AQUAProcessor M 5700 C TOUCH primary function is to control the chlorine gas dosing on basis of data received from chlorine analyzer and/or water flow meter. There are three types of controls available and multiple individual dosing points can be controlled. AQUAProcessor M 5700 C TOUCH secondary function is to control complete station: booster pump control, empty cylinder control, chlorine gas leakage control, chlorine gas neutralisation system control, emergency cylinder shut off system control, fan operation control, ect. AQUAProcessor M 5700 C TOUCH is also able to communicate with SCADA software. The device can send all the relevant data to SCADA control software and receive commands from SCADA. Available regulation types for automatic dosing of chlorine gas in water: flow-proportional controller residual chlorine controller combination of flow-proportional and residual chlorine controller in one unit The proper regulation for each individual system can easily be set on the field. The electronically controlled motor valve is driven through PID regulator at all types of co

Open the catalog to page 1

3 Regulation & Control equipment ORDER CODE Model Number of dosing points Gas type LCD size OPTIONS: - Number of dosing points: ''1'' - One dosing point flow proportional and/or residual controller ''2'' - Two dosing points flow proportional and/or residual controller ''3'' - Three dosing points flow proportional and/or residual controller ''X'' - Multi dosing points flow proportional and residual controller - Gas type: ''C'' = chlorine - LCD size: ''S'' for standard 3,5'' LCD display; 5'' and 7''LCD available on request! TECHNICAL DATA Power supply: 220 VAC Display: min. 3,5’’ TOUCH LCD to...

Open the catalog to page 2All Controlmatik catalogs and technical brochures

-

MR 520 C, MR 540 C, MR 550 C

2 Pages

-

MR 50 RC

2 Pages

-

MR 40 RC

2 Pages

-

MR 21 RC

2 Pages

-

MR 20 RC

2 Pages

-

M 30 RC

2 Pages

-

M 470 C PVC

2 Pages

-

M 3800

2 Pages

-

M 2103 C

2 Pages

-

M 4510 C

2 Pages

-

M 5265 C

2 Pages

-

automation

1 Pages

-

M 1322

2 Pages

-

M 1122

2 Pages

-

M 1056 C

2 Pages

-

M 1036 C

2 Pages

-

M 1035 C

2 Pages

-

MR 520, 540 & 550 RC

2 Pages

-

M 20 RC

2 Pages

-

M 3610 C

2 Pages

-

M 3480 C

2 Pages

-

M 3100 C

2 Pages

-

M 3319 C

2 Pages

-

M 3531 C

2 Pages

-

M 300 C

2 Pages

-

DP 20, DP 40, DP 50

2 Pages

-

M 200 C

2 Pages

-

M 20 C

2 Pages

-

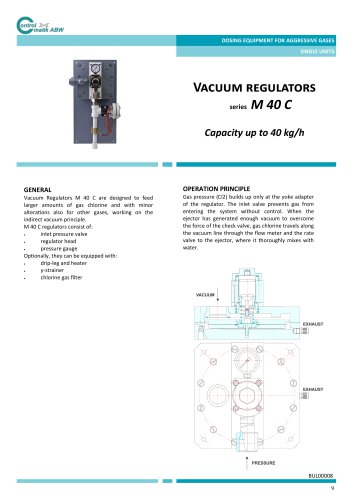

M 40 C

2 Pages

-

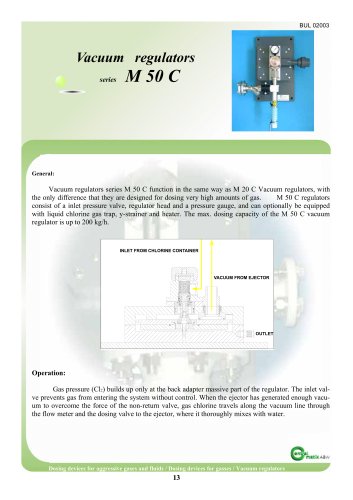

M 50 C

2 Pages

-

Compat filtration unit

2 Pages

-

Vacuum switchover M 400

2 Pages

-

Aquacon M 5500 C

2 Pages

-

M 5262 C

2 Pages

-

M 5600 C

2 Pages

-

M 1032 C/ADCR1

2 Pages

-

M 400 and M 440

2 Pages

-

M 3521 C

2 Pages

-

M 340 C and M 350 C

2 Pages

-

M 40 C

2 Pages

-

Vacuum Regulators M 50

2 Pages

-

Vacuum Regulators M 20

2 Pages