Catalog excerpts

1 Dosing equipment for aggressive gases Chlorine gas pressure reducing valve M 3480 C The M 3480 C gas chlorine pressure reducing valve is used to sink down the unregulated gas pressure to a steady operating gas pressure. The pressure reducing valve secures pressure independent operation of Vacuum regulator and prevents, in relation to pressure and temperature changes, liquefaction of chlorine gas. OPERATION PRINCIPLE Through the adjustable screw the valve cone can be lifted above the valve seat within defined limits, so that the operating pressure can be set to any value between 2 and 3 bar for Cl2. Pressure fluctuations are compensated by the spring-loaded double diaphragm system, so that the operating pressure is kept constant (at constant flow). If the operating pressure exceeds the set value, the spring-cone diaphragm system enables the valve to close. Assures steady operating pressure Capacity: up to 200 kg/h Spring-loaded double diaphragm system The gas chlorine pressure reducing valve is always mounted in a chlorine system, so the installation depends very much on the system. When taken from the packing box, the valve must be mounted as soon as possible, in other case it must be stored in a dry place. No moisture should enter the valve! A valve has two flanges and is mounted in the chlorine gas system pressure line with counter flanges and tightens up with screws. The valve must be mounted to the wall or to a construction with the attached L-piece. If the pressure gauge is mounted onto the valve, than it must be mounted before the valve is mounted. To do that, remove the plug screw. Prepare the pressure gauge and put some special chlorine gas resistant glue on the screw. Screw the pressure gauge in and remove the surplus glue with the rag. Watch how the scale is turned. Now the correct pressure can be set.

Open the catalog to page 1

1 Dosing equipment for aggressive gases ORDER CODES Model Gas type Capacity Pressure gauge OPTIONS: - Gas type: “C” - Cl2, “CO2” - CO2, “S” - SO2, “N” - NH3 - Capacity: 40 up to 40 kg/h 200 up to 200 kg/h - Pressure Gauge: if selected letter »M« is written in the model number TECHNICAL DATA Nominal pressure: 16 bar Output pressure adjustable: 0-3 bar (Cl2) Weight: 12,5kg Materials: Diaphragm: Silver Valve seat: PVDF for Cl2 Spring: Hastelloy C, silver-plated O-Rings: Viton for Cl2 Enclosure: Brass for Cl2 Optional: Output gas pressure gauge Connection: R1/4”, range 0-16 bar up to 40 kg/h...

Open the catalog to page 2All Controlmatik catalogs and technical brochures

-

MR 520 C, MR 540 C, MR 550 C

2 Pages

-

MR 50 RC

2 Pages

-

MR 40 RC

2 Pages

-

MR 21 RC

2 Pages

-

MR 20 RC

2 Pages

-

M 30 RC

2 Pages

-

M 470 C PVC

2 Pages

-

M 3800

2 Pages

-

M 2103 C

2 Pages

-

M 4510 C

2 Pages

-

M 5265 C

2 Pages

-

automation

1 Pages

-

M 5700 C

2 Pages

-

M 1322

2 Pages

-

M 1122

2 Pages

-

M 1056 C

2 Pages

-

M 1036 C

2 Pages

-

M 1035 C

2 Pages

-

MR 520, 540 & 550 RC

2 Pages

-

M 20 RC

2 Pages

-

M 3610 C

2 Pages

-

M 3100 C

2 Pages

-

M 3319 C

2 Pages

-

M 3531 C

2 Pages

-

M 300 C

2 Pages

-

DP 20, DP 40, DP 50

2 Pages

-

M 200 C

2 Pages

-

M 20 C

2 Pages

-

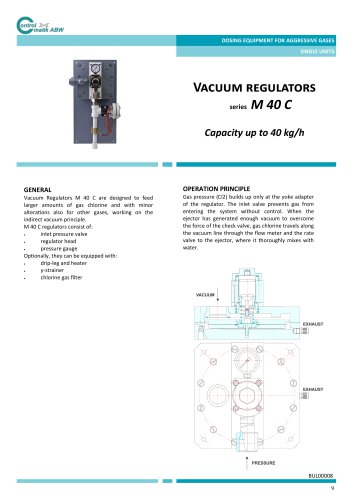

M 40 C

2 Pages

-

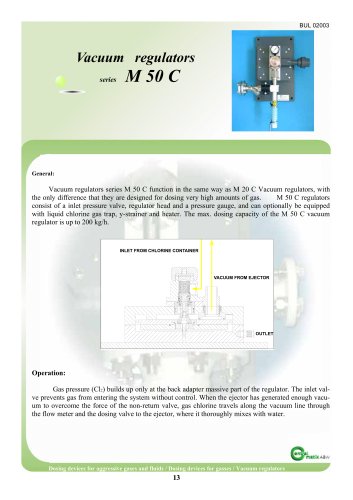

M 50 C

2 Pages

-

Compat filtration unit

2 Pages

-

Vacuum switchover M 400

2 Pages

-

Aquacon M 5500 C

2 Pages

-

M 5262 C

2 Pages

-

M 5600 C

2 Pages

-

M 1032 C/ADCR1

2 Pages

-

M 400 and M 440

2 Pages

-

M 3521 C

2 Pages

-

M 340 C and M 350 C

2 Pages

-

M 40 C

2 Pages

-

Vacuum Regulators M 50

2 Pages

-

Vacuum Regulators M 20

2 Pages