Catalog excerpts

1 Dosing equipment for aggressive gases High heating efficency Low operation and maintenance costs Evaporators series M 3100 C are designed to heat liquid chlorine taken from storage containers and turn it to chlorine gas. Modification of the traditional evaporator design is a result of growing demand for lower operation and maintenance cost and for higher heating efficiency. The evaporators series M 3100 C are specially suitable for installations where large quantities of gas are required directly from gas drums. Evaporation is achieved mainly by electric heating. The unit consists of regulation, control and safety devices as well as the separate control panel. All parts except the control panel are built-in the fibre glass reinforced polyester cabinet. Turns liquid chlorine to gas Simple assembly and installation refilled if the level drops under the prescribed level. All exposed parts are made of materials or material combinations which are absolutely resistant to the media that needs to be evaporated, and which are proven to resist many years of use. OPERATION PRINCIPLE The spiral tube is immersed into an hot water bath of 70°C. The thermostat-regulated heating creates a constant temperature. In case of temperature drop (below 60°C) or temperature rise (above 80°C), the alarm is activated. The liquid gas under pressure enters the evaporator on the top part, where it evaporates in the progressive heating zone and then leaves it as a dry saturated gas, also on the top part. In order to protect the installations (up to the pressure reducing valve) from re-liquefaction of the gas, the evaporator is designed generously, considering the gas outlet temperature. In liquid side of the system, the bursting disk with connected expansion chamber ensures that the highest admissible operating pressure is not exceeded. This chamber is dimensioned in a way that transforms the overpressure after the bursting of the bursting disc into the normal operating pressure. On the gas side a pressure relief valve must be installed after a bursting disc and outlet must be connected to the neutralization device. A contact manometer indicates too high or to low gas pressure. Water level in a thermal bath is strictly monitored and water must be LEGEND: 1. Scale 2. Ton Container 3. Bursting membrane with expansion chamber 4. Evaporator 5. Pressure gauge 6. Exhaust pressure safety valve 7. Chlorine gas filter 8. Pressure reducing valve 9. Chlorine gas Leak detector

Open the catalog to page 1

1 Dosing equipment for aggressive gases ORDER CODES Model Gas type Capacity OPTIONS: - Gas type: “C” - Cl2 - Capacity: 50 up to 50 kg/h 100 up to 100 kg/h 150 up to 150 kg/h 200 up to 200 kg/h Higher capacities on request! TECHNICAL DATA Evaporator capacity: 30 - 200 kg/h Power Supply: 400 V 50-60Hz Consumption: 9 kW—18kW Operating pressure: Cl2: max 16 bar H2O: max 8 bar Test pressure: 20 bar Construction weight: cca 450kg Temperature: Operating: 70ºC Max. 80ºC - Min. 60ºC Connections Inlet Gas: DN15 NP40 Outlet Gas: DN20 NP40 Inlet Water: R3/4" Outlet Water: R3/4" Other connections on...

Open the catalog to page 2All Controlmatik catalogs and technical brochures

-

MR 520 C, MR 540 C, MR 550 C

2 Pages

-

MR 50 RC

2 Pages

-

MR 40 RC

2 Pages

-

MR 21 RC

2 Pages

-

MR 20 RC

2 Pages

-

M 30 RC

2 Pages

-

M 470 C PVC

2 Pages

-

M 3800

2 Pages

-

M 2103 C

2 Pages

-

M 4510 C

2 Pages

-

M 5265 C

2 Pages

-

automation

1 Pages

-

M 5700 C

2 Pages

-

M 1322

2 Pages

-

M 1122

2 Pages

-

M 1056 C

2 Pages

-

M 1036 C

2 Pages

-

M 1035 C

2 Pages

-

MR 520, 540 & 550 RC

2 Pages

-

M 20 RC

2 Pages

-

M 3610 C

2 Pages

-

M 3480 C

2 Pages

-

M 3319 C

2 Pages

-

M 3531 C

2 Pages

-

M 300 C

2 Pages

-

DP 20, DP 40, DP 50

2 Pages

-

M 200 C

2 Pages

-

M 20 C

2 Pages

-

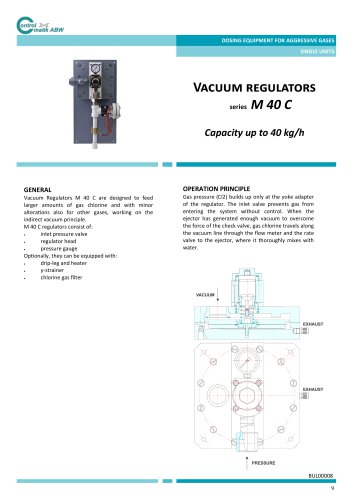

M 40 C

2 Pages

-

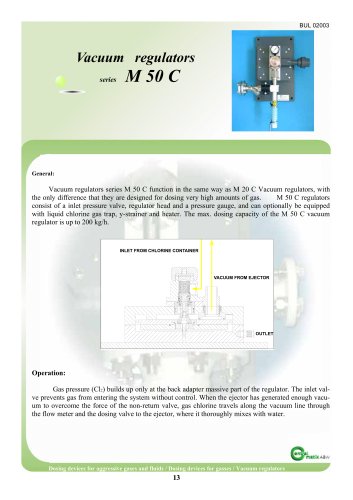

M 50 C

2 Pages

-

Compat filtration unit

2 Pages

-

Vacuum switchover M 400

2 Pages

-

Aquacon M 5500 C

2 Pages

-

M 5262 C

2 Pages

-

M 5600 C

2 Pages

-

M 1032 C/ADCR1

2 Pages

-

M 400 and M 440

2 Pages

-

M 3521 C

2 Pages

-

M 340 C and M 350 C

2 Pages

-

M 40 C

2 Pages

-

Vacuum Regulators M 50

2 Pages

-

Vacuum Regulators M 20

2 Pages