Catalog excerpts

NEW INDUCTIVE SENSORS • Full Inox Basic with lO-Link • Full Inox Weld-Immune, M8 • Full Inox C23, cubic with IO-Link • High Temperature, 230°C (440°F) PHOTOELECTRIC SENSORS • Contrast sensor with IO-Link • C12: Cubic Subminiature • C23: Cubic with IO-Link • C23 Distance: Triangulation • C55 Distance: TOF SAFETY • Type 2 light curtains for hand protection RFID • LF + HF R/W modules in ContriNet • HF tags for 180°C (356°F), embeddable in metal • HF tags for 250°C (482°F) • EtherCat interface

Open the catalog to page 1

INTRODUCTION CONTRINEX Contrinex is a leading manufacturer of sensors for factory automation. The Swiss company, headquartered in Givisiez near Fribourg (CH), has a unique and innovative range of products whose features far surpass those of standard sensors. Since its foundation in 1972 by Peter Heimlicher, Dipl Ing ETH, Contrinex has grown from a one-man operation to a multinational group with over 500 employees worldwide. More than 15 subsidiaries cover the core markets in Europe, Asia, North and South America. At a glance • Technology leading manufacturer of inductive and photoelectric...

Open the catalog to page 2

Intelligent Sensors for the 4th Industrial Revolution: Industry 4.0 Fit for the future with IO-Link Intelligent sensors are the fundamental building blocks of modern smart factories. They enable sensorsupported production resources (machines, robots, etc.) to configure, control, manage and optimize themselves. Precise, reliable sensor data is now more essential than ever. Sensors from Contrinex, the leader in intelligent sensor technology, ensure excellent data quality. To communicate that data, all Contrinex inductive and photoelectric ASIC sensors will be equipped with IO-Link as...

Open the catalog to page 3

Sensor business starts with self-contained subminiature inductive sensors: Ø4 mm (instead of M8 before) Launch of inductive sensor with patented Condist® technology – market leadership with operating distances 3x standard Launch of Ø3 mm inductive sensors, now market leader for subminiature inductive sensors Market launch of Ø4 mm subminiature photoelectric sensors Launch of world’s first inductive sensor with full-metal housing – thanks to patented Condet® technology Integration of Contrinex’s excellent performance for inductive sensors in CMOS-ASIC (Application-Specific Integrated...

Open the catalog to page 4

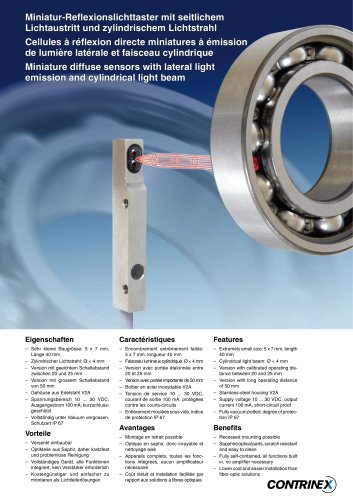

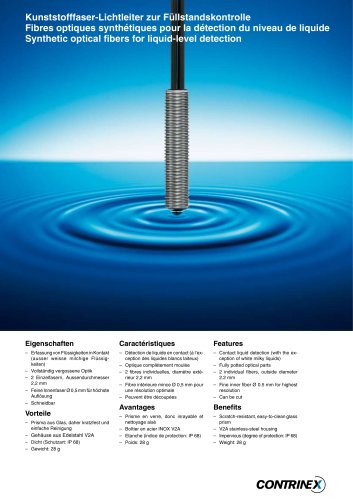

CONTRINEX PRODUCT RANGES SENSORS SAFETY INDUCTIVE BASIC MINIATURE EXTREME EXTRA PRESSURE HIGH PRESSURE EXTRA TEMPERATURE HIGH TEMPERATURE WASHDOWN ANALOG OUTPUT 2-WIRE WELD-IMMUNE SPECIAL PHOTOELECTRIC CYLINDRICAL SUBMINIATURE CYLINDRICAL MINIATURE CYLINDRICAL SMALL CUBIC SUBMINIATURE CUBIC MINIATURE CUBIC SMALL CUBIC COMPACT FIBER-OPTIC AMPLIFIERS, FIBERS ULTRASONIC MINIATURE SMALL COMPACT CAPACITIVE BASIC HIGH PERFORMANCE LIGHT CURTAINS FINGER PROTECTION type 4 HAND PROTECTION type 4 and type 2 SAFETY RELAYS ACCESS CONTROL type 4 RFID LOW AND HIGH FREQUENCY TRANSPONDERS CONTRINET USB...

Open the catalog to page 5

INDUCTIVE PHOTOELECTRIC S Presence detection of metal objects S Position control of all kinds of metal targets S Counting tasks S Distance control on end positions S Quality control S Sensing of light reflective objects S Position control of cartons and other objects on conveyors S Detection of small objects over large distances 8 I Detailed data sheets for these products can be found on the Contrinex website:

Open the catalog to page 6

Any material that reflects sounds Metals, non-metals, liquids, powders For industrial environments, with protection class up to IP 67 For normal or demanding environments, with protection class up to IP 67 ü Detection of all objects that reflect ultrasound ü Monitoring of winding and unwinding processes ü Liquid level control ü Loop tension control ü Position feedback ü Distance or height control ü Level control of fluids, bulk materials and powder ü Presence detection of almost all materials ü Counting tasks for non-metallic materials ü Detection through non-metallic container walls

Open the catalog to page 7

Today, sensors of all types are common in automotive factories around the globe. Highly automated plants with demanding conformity requirements rely heavily on sensor technology to maintain world-class quality standards, particularly where harsh processes such as welding, metal finishing and high-temperature coating are required. Manufacturing engineers working for automotive manufacturers and for first- and second-tier suppliers expect robust, reliable sensors that deliver accurate, repeatable results with minimal downtime. Recommended product ranges: Inductive - Full Inox -...

Open the catalog to page 8

Machine tools impose harsh operating conditions on the sensors needed to control cutting, forming and joining processes that run continuously in many metalworking factories. Common hazards include cutting fluid, cooling sprays, swarf particles and electromagnetic interference, making sensor selection particularly difficult where world-class performance is essential. Size is another key factor, as modern tool-holders allow only limited space for the sensors needed to identify and position individual tools during rapid tool-changing. The right sensors contribute to efficient production,...

Open the catalog to page 9

Machinery manufacturers supplying the textile, leather and clothing industries rely on sensors for efficiency, reliability and precision. World-class accuracy is essential for production of technical textiles and for making the carbon or chemical fibers used in modern, innovative products, often in highly automated factories. The high-speed machinery used by textile manufacturers must operate continuously and safely, relying on top-quality sensors for all aspects of access and control. The environmental challenges include industrial cleaning routines that test every sensor to the limit of...

Open the catalog to page 10

The Green Economy relies heavily on technology for its continued advancement, and sensors are a major component of any eco-friendly strategy. Environmental initiatives include wind-, wave- and solar-power generation, industrial and domestic recycling, energy management and development of alternative fuels. To deliver the green agenda, all of these sectors utilize sensors extensively for reliable detection and identification of materials, accurate measurement of operational parameters and consistent control of processes. Recommended product ranges: Inductive - Full Inox - Washdown Inductive...

Open the catalog to page 11All CONTRINEX catalogs and technical brochures

-

RFID Catalog

64 Pages

-

Safety Catalog

48 Pages

-

Program Overview

20 Pages

-

General catalog Inductive 16/17

168 Pages

-

General catalog Capacitive 16/17

32 Pages

-

General catalog Safety 16/17

50 Pages

-

General catalog RFID 16/17

63 Pages

-

General catalog Glossary 16/17

21 Pages

-

General Catalog 2016-2017

493 Pages

-

News catalog winter 16/17

28 Pages

-

Inductive Extreme Flyer

2 Pages

-

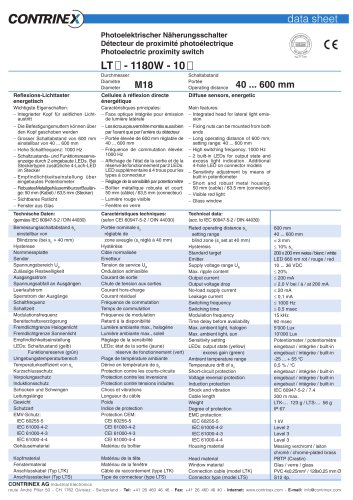

LTS-4050-101

3 Pages

-

LTK-1180W-101

2 Pages

-

LTK-1120-301

2 Pages

-

LTK-1040-301

2 Pages

Archived catalogs

-

Winter 2012 / 2013 NEWS

16 Pages

-

Multi-beam synthetic fiber

2 Pages

-

Sensor-Tester

2 Pages