Website:

Conductix-Wampfler

Website:

Conductix-Wampfler

Group: Delachaux Group

Catalog excerpts

Wireless Charger 3.0 Program 9200

Open the catalog to page 1

Wireless Charger 3.0 Powerful | Reliable | Efficient Wireless Charger 3.0 is a highly efficient power transfer system, ideal to provide electric power to charge batteries. Wireless Charger 3.0 meets the more and more demanding requirements modern logistic solution ask for. Offering best-inclass charging to fully automated transport solutions, being very robust, having no vulnerable contact surface, providing high efficiency Wireless Charger 3.0 allows highly dynamic and flexible transport solutions, at an extremely competitive cost level compared to other solutions so far considered for...

Open the catalog to page 3

Wireless Charger 3.0 A short introduction Principle It always looks like a wonder, that power is transferred through air. But the principles are known since a long time. Faraday and Maxwell are just two of the scientists working out the basics. Nikolas Tesla was, in addition to his breakthrough works on electrical motors and AC grid systems, famous for his works on wireless power transfer. While he looked on power transfer over large distances, the Wireless Charger 3.0 focuses on distances defined by the operation practicability on vehicles served. Magnetic fields are designed and optimized...

Open the catalog to page 4

Wireless Charger 3.0 Charging The Batteries Conductix-Wampfler batteries are built up from long term proven battery cells. Power type cells and energy type cells, both using NMC technology, are available for various applications. Batteries are offered together with other Conductix-Wampfler products as a well aligned bundle. The overall design of Conductix-Wampfler batteries takes a big step forward to achieve robust and versatile battery systems for challenging industry use cases. Conductix-Wampfler batteries are particularly characterized by: - Robust and compact packaging, targeting to...

Open the catalog to page 5

Wireless Charger 3.0 Components Functional Components The IPS (Inductive Power Supply), converts the 50 or 60 Hz mains frequency into a high frequency allowing highly efficient power transfer. Charging requirements and other information coming from the Battery management system onboard the vehicle is taken up by the ISP and transferred in corresponding action. If you want to say so, the IPS is the heart and the brain of the Wireless Charger 3.0. Mains required is 230 V (200 – 270 V) 2-phase, fused at 16 Amps. The ISP (Inductive Stationary Pad), includes the sending coil for the power...

Open the catalog to page 6

Wireless Charger 3.0 Operating Principle Functional Structure Power In (AC 2p) Temperature Ethernet (optional use) Enable / Disable 1 Plant Control System 2 Vehicle Control System 3 Battery Management System

Open the catalog to page 7

Wireless Charger 3.0 Arrangements Requirements Wireless Charger 3.0 is providing implementation freedom. There is no preferred or required mounting orientation for the pads. Depending on vehicle design, available installation space and building structures in the operational environment the chargers can be installed horizontally or vertically. Vertical Arrangement The vertical arrangement doesn`t require the mounting on a specific side of the vehicle. Practice is in most cases to mount the IMP (Inductive Mobile Pad) on the left or the right side of the vehicle, so that a drive through...

Open the catalog to page 8

Wireless Charger 3.0 Arrangements Horizontal Arrangement The horizontal arrangement is simply fixing the ISP (Inductive Stationary Pad) with 4 screws (at least 2) on the floor. A flat even floor underneath is recommendable to provide mechanical stability to the ISP, hollow spaces underneath should be filled with spacers if floor is not flat. A second version of floor based installation is the floor embedded installation. Works on the floor itself are necessary to make cut-outs for the ISP and the feeding cable. The full integration installation`s benefit is the undisturbed floor level,...

Open the catalog to page 9

Wireless Charger 3.0 Set Stationary Side IPS 3.0 | Inductive Power Supply Nominal Power Supply Voltage Input Current Rating Output Current Rating Operating Frequency Interfaces in use with Wireless Charger 3.0 Environmental Conditions for industrial applications, indoor, dry and clean, no special requirements Operating Temperature Convection – Passive Mounting Orientation Protection Class Accessories (optional) Nominal Power Cable Lengths Cable Termination and Cut to Length Operating Frequency Power Cable + Temperature Signal Accessories (optional) Frame Floor Mounting Frame Vertical...

Open the catalog to page 10

Wireless Charger 3.0 Set Vehicle Side IMP 3.0 | Inductive Mobile Pad Nominal Power (Maximum) Exclusively with Components Wireless Charger 3.0, 3 kW Cable Lengths Cable Termination Power Cable + Temperature Signal Environmental Conditions for industrial applications, indoor, dry and clean, no special requirements Operating Temperature Convection – Passive Mounting Orientation Protection Class Nominal Power (Maximum) Exclusively with Components Wireless Charger 3.0, 3 kW Output Voltage Output Current Output Connection Terminals (Power) MPU 3.0 | Mobile Power Unit Environmental Conditions for...

Open the catalog to page 12

Wireless Charger 3.0 Accessories Mounting Frame In combination with Inductive Stationary Pad (ISP) 3.0, 3 kW or Wireless Charger Set WCS 3.0, 3 kW Environmental conditions Standard Indoor, no specific requirements in respect to chemicals and temperatures Held in position by Inductive Stationary Pad (ISP), no extra holes and screws Set of Plugs for IPS 3.0 | Inductive Power Supply The frame Floor Mounting provides extra mechanical protection to the Inductive Stationary Pad (ISP) in respect to forces on the sides or the top edges. At the same time the frame provides a smooth incline and...

Open the catalog to page 15

Wireless Charger 3.0 FAQs Charging many vehicles on a Charging Station? While charging is in process, there is always a 1:1 link between the Charging Station and the vehicle to charge. But this does not mean this is generally the case of the Charging Station, any suitable vehicle can use any free Charging Station. Typically, you usually have more vehicles than Charging Stations in a facility. This may not be always the case, i.e. with 1 or 2 shift operation and long-time windows for charging it might be a consideration to have a Charging Station per vehicle. But even then, it is to keep in...

Open the catalog to page 16All Conductix-Wampfler catalogs and technical brochures

-

CGR Slip Rings

6 Pages

-

Jay RadioSafe

6 Pages

-

Product Overview Motorized Reels

28 Pages

-

Product Overview Conductor Rails

20 Pages

-

Product Overview Cables

16 Pages

-

Motor Driven Reels - MAG Drive

20 Pages

-

Industrial Spring Reels

28 Pages

-

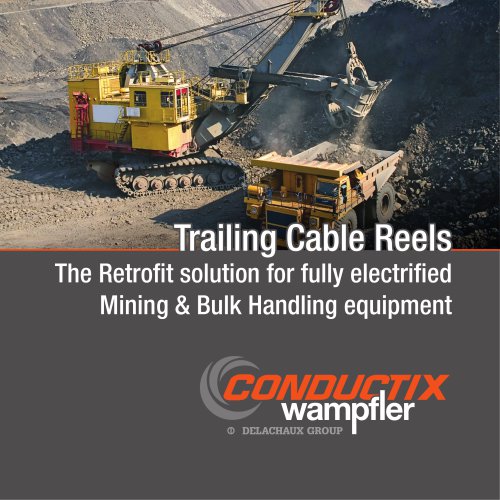

Trailing Cable Reels

4 Pages

-

Festoon Systems for I-Beams

36 Pages

-

LM Series

6 Pages

-

Drive-In

4 Pages

-

Jib Booms Program 0420

24 Pages

-

Fiber optic Spring Reels

2 Pages