Website:

Conductix-Wampfler

Website:

Conductix-Wampfler

Group: Delachaux Group

Catalog excerpts

Slip Ring Assemblies Program 5100

Open the catalog to page 1

Conductix-Wampfler - an experienced partner Conductix-Wampfler offers a wide range of rotary transmissions, for energy, data and signal transmission as well as for the transmission of gasiform and fluid medias. The standard program allows to install slip ring assemblies for power and data/signal currents of any number of poles. Combinations that include additional rotary transmissions for liquid media (water, hydraulic oil, oil etc.) and gases (compressed air, argon etc.) are possible. Slip ring assemblies can be either supplied as an open built-in version that is adjusted to the customers’...

Open the catalog to page 5

General Example of a Combined Slip Ring Assembly Ring core wiring on terminal board Multiple brush holder assembly for signal and data transmission Double brush holder assembly 90 A Double brush holder assembly 150 A Double brush holder assembly 250 A Entries for wiring Driving flange with ball bearing Combined slip ring assembly GS2104 / 1904 / 1504 / 1806 / 04 ML 3 x 250 A + PE + 4 x 150 A + 4 x 90 A + 6 x 25 A + 4 x Data

Open the catalog to page 6

General A Developed and Comprehensive Standard Program Some examples of slip ring applications: rotary cranes, water treatment works, roundabouts, manipulators, rotary tables, antenna arrays, theatre stages, packing machines and cable reels. Rotating die-casting equipment of Krauss-Maffei Kunststofftechnik (Munich); in operation at Johnson Controls Interiors (Lüneburg) Slip ring assembly in building machinery Slip ring assembly in elevating platforms

Open the catalog to page 7

Electrical data • Voltage: - max. 400V~= (415 V)1' - according to DIN VDE 0110 - overtension category III - insulating material group II - degree of contamination 3 • Current: mA to 16 A, at max. 30°C and 100% duty cycle • Slip rings: - 0 30 x 6 mm, brass (MS) - distance between rings 12 mm • Brush holder assembly: - brush holders with 2 pressed-in brushes (Cu) 20 x 6.4 mm - Connecting flat plug 4.8 (DIN 46244) for flat socket 4.8 (DIN 46247) • Protection class: IP 00 Control and data transmission • Ring with multi-layer coating (ML) and silver (Ag) brush holder assembly for the transfer of...

Open the catalog to page 8

13 - 18 poles with insulated terminals Electrical data • Voltage: - max. 400V~= (415 V)1' - according to DIN VDE 0110 - overtension category III - insulating material group II - degree of contamination 3 • Current: mA to 25 A, at max. 30°C and 100% duty cycle • Slip rings: - 0 45 x 8 mm, brass (MS) - distance between rings 14 mm • Brush holder assembly: - brush holders with 2 pressed-on brushes (Cu) 20 x 8 mm - Connecting flat plug 6.3 (DIN 46244) for flat socket 6.3 (DIN 46247) • Protection class: IP 00 Control and data transmission • Ring with multi-layer coating (ML) and silver (Ag)...

Open the catalog to page 9

Electrical data • Voltage: - max. 1000 V~= - according to DIN VDE 0110 - overtension category IV - insulating material group II - degree of contamination 3 • Current: 25 A, at max. 30°C and 100% duty cycle • Slip rings: - 0 45 x 8 mm, brass (MS) - distance between rings 28 mm • Brush holder assembly: - brush holders with 2 pressed-on brushes (Cu) 20 x 8 mm - Connecting flat plug 6.3 (DIN 46244) for flat socket 6.3 (DIN 46247) • Protection class: IP 00 Wiring and max. number of poles • Max. 9 (incl. PE) • Completely wired with 2.5 mm2 on a terminal board (terminal posts) Additional technical...

Open the catalog to page 10

Electrical data • Voltage: - max. 1000V~= - according to DIN VDE 0110 - overtension category IV - insulating material group II - degree of contamination 3 • Current: 47 A, at max. 30°C and 100% duty cycle • Slip rings: - 0 45 x 17 mm, brass (MS) - distance between rings 36.6 mm • Brush holder assembly: - brush holders with 2 brush holders and brushes with two pressed-on brushes (Cu) 20 x 8 mm - connecting flat plug 6.3 (DIN 46244) for flat socket 6.3 (DIN 46247) • Protection class: IP 00 Wiring and max. number of poles • Max. 5 (incl. PE) • Completely wired with 6 mm2 on a terminal board...

Open the catalog to page 11

Slip Ring Assembly Built-in Slip Ring Assembly ES18 25 A /630 V (690 V) min. ø 220 ø 60 Standard type Construction without terminal board Construction with additional support Components included • Slip ring assembly without brush bolt • Brush holder assemblies loosely enclosed • On request with brush bolt possible Wiring and max. number of poles construction: - up to 4 rings without terminal board - 6 to 36 rings on a terminal board with 2.5 mm² (terminal posts) - 37 to 48 rings with strand wiring 1,5 mm², 2 m from flange, without terminal board • Special construction: - up to 48 rings...

Open the catalog to page 12

Electrical data • Voltage: - max. 630V~= (690V)1' - according to DIN VDE 0110 - overtension category III - insulating material group II / III - degree of contamination 3 • Current: mA to 25 A, at max. 30°C and 100% duty cycle • Slip rings: - 0 102 mm, brass (MS) - distance between rings 15 mm • Brush holder assembly: - brush holders with 2 contact springs, each with 3 bronze brush (Br) rivets - connection: cable lug ring form M4 (DIN46237) or insulated flat socket 6.3 (DIN46245) • Protection class: IP 65 Control and data transmission • Ring with multi-layer coating (ML) and silver (Ag)...

Open the catalog to page 13

Electrical data • Voltage: - max. 1000V~= - according to DIN VDE 0110 - overtension category IV - insulating material group II / III - degree of contamination 3 • Current: 50 A, at max. 30°C and 100% duty cycle • Slip rings: - 0 85 x 12 mm, brass (MS) - distance between rings 17 mm - connection M 6 • Brush holder assembly: - industrial double brush holder with two articulating brushes (Cu) 22 x 6.4 mm - connection M 5 • Protection class: IP 00 Construction with strand wiring Wiring and max. number of poles • Max. 28 (incl. PE) completely wired with 10 mm2 • Up to 14 poles on terminal...

Open the catalog to page 14

Electrical data • Voltage: - max. 1000V~= - according to DIN VDE 0110 - overtension category IV - insulating material group II / III - degree of contamination 3 • Current: 90 A at max. 30°C and 100% duty cycle • Slip rings: - 0 85 x 15 mm, brass (MS) - distance between rings 20 mm - connection M 8 - max. 100A • Brush holder assembly: - industrial double brush holders with two articulatings brushes (Cu) 25 x 8 mm - connection M 6 - max. 90A • Protection class: IP 00 Wiring and max. number of poles • Max. 16 (incl. PE) completely wired with 16 mm2 • Up to 8 pole on a terminal board, connected...

Open the catalog to page 15All Conductix-Wampfler catalogs and technical brochures

-

CGR Slip Rings

6 Pages

-

WirelessCharger 3.0

20 Pages

-

Jay RadioSafe

6 Pages

-

Product Overview Motorized Reels

28 Pages

-

Product Overview Conductor Rails

20 Pages

-

Product Overview Cables

16 Pages

-

Motor Driven Reels - MAG Drive

20 Pages

-

Industrial Spring Reels

28 Pages

-

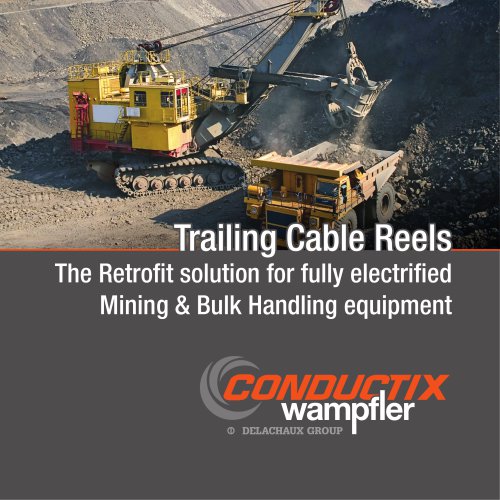

Trailing Cable Reels

4 Pages

-

Festoon Systems for I-Beams

36 Pages

-

LM Series

6 Pages

-

Drive-In

4 Pages

-

Jib Booms Program 0420

24 Pages

-

Fiber optic Spring Reels

2 Pages