Website:

Conductix-Wampfler

Website:

Conductix-Wampfler

Group: Delachaux Group

Catalog excerpts

ProEMS Insulated Conductor Rail for Electrified Monorail Systems Program 0815 ©JNDUQTIX wampfler

Open the catalog to page 1

Supplementary Documents Installation instructions: MV0815-0007-EN Installation Instructions for Conductor Rail System 0815 MV0815-0005-D Installation Instructions for Expansion Units and Expansion Elements MV0815-0008-0001-EN Mounting the BCB Support Profile (SEW) MV0815-0002-D Current Collector 0815 – Replacement Instructions Operating instructions: BAL0800-0002-D Operating Instructions for Rail Cleaners Maintenance instructions WV0800-0001-D Cleaning of Conductor Rails WV0800-0002-CS Maintenance Schedule Conductor Rails WV0800-0004-D Copper Rail Applications

Open the catalog to page 2

Layout Tips9 System Layout10 Conductor Rails / Curves 11 Rail Connectors / Power Feeds 13 Cables for Power Feeds / Hanger Clamps 14 End Caps18 Air Gaps, Expansion Units 19 Current Collectors and Accessories 23 Replacement and Spare Parts / Accessories28 Optional Accessories30 Installation Tools 32

Open the catalog to page 3

Electrified monorail systems (EMSs) are now an integral part of many production and logistics processes and are spreading into many new fields of application beyond traditional automotive assembly. In addition to logistics, applications ranging from the transport of personnel or materials to the transport of cut flowers or seedlings are now practically standard. Different system parameters and environmental conditions as well as new and unforeseen influences must be considered at an early stage in the design and planning phase. As your partner for energy and data transmission systems,...

Open the catalog to page 4

ProEMS 0815 for Electrified Monorail Systems – Project Planning The ProEMS conductor rail system system has been used for several decades in a variety of applications, and its components have been adapted for the most diverse conditions. As some applications rule out functionalities or components, this catalog has been compiled to give an accurate overview of the system components intended for electrified monorail systems. In addition to the components tailored for electrified monorail systems in accordance with guidelines and automotive-manufacturing requirements, this document includes...

Open the catalog to page 5

ProEMS 0815 for Electrified Monorail Systems • PEplus protective earth system (to automotive standard) Conductix-Wampfler’s PEplus grounding system prevents the ground collector from being accidentally inserted into a phase rail. The grounding collector is wider than a phase collector and cannot be inserted into a phase rail by mistake, unless excessive force is used. Insertion of a PEplus current collector into a phase rail is thus prevented and any faulty installation would be immediately obvious. The system is backward compatible with the old PE system and can be retrofitted in stages...

Open the catalog to page 6

ProEMS 0815 for Electrified Monorail Systems • nstallation position of the current collector / distance between the contact point and the wheel contact point I Due to curves and inclines, particular attention must be paid to the installation position of the current collector. The ideal installation position is directly below the wheel contact point of the carriage. If the installation is away from this ideal point, there will be different distances between the current collector connection to the carriage (usually a maintenance hatch) and the running surface of the current collector in the...

Open the catalog to page 7

Note: Subject to technical changes. Applications other than those described here or different framework conditions require consultation to check their technical feasibility. Technical specifications may be mutually restrictive. In case of doubt, we also recommend checking the suitability. 1) EMS vehicles are supplied in sections via several power feed points. The system is designed with a conductor cross section of 25 mm2. The maximum current-carrying capacity is determined by the wiring and number of power feeds. 2) The current-carrying capacity of power feed connectors, end-cap units, and...

Open the catalog to page 8

Layout Tips Circuit Breakers / Overload Protection Depending on the system layout, the maximum permissible loads of the individual components must be taken into account in addition to the cable lengths / loop resistances. Permissible Current Load The conductor rail system is designed with a conductor cross section of 25 mm². The maximum current-carrying capacity is determined by the power feed and the type of cable used, the cross section, and the type of installation of the power feed. The installation space limits expansion modules and the factory cabling to 54 A. Temperature-dependent...

Open the catalog to page 9

System Layout System Layout System layout with travel direction to the right L2 L3 PE C1 C2 Minimum distance of the rail insulation from metallic components: 5 mm “Wheel contact point” Main direction of travel Hanger-clamp interval: 500 mm (linear tracks) 400 mm (horizontal curves) 250 mm (vertical curves) 40 mm Ideal installation position EMS current collector unit Towing arm with current collectors including PEplus func

Open the catalog to page 10

The rails are available in the installation-optimized length of 4000 mm with yellow insulation (RAL 1018) as a phase rail or as protective earth in a yellow-green version in accordance with standards. 1) Special length of 6 m on request 2) Existing systems without PEplus * Standard series PEplus Rail Polarity Protection Protective earth current collectors with PEplus have a wider design than phase current collectors and match the width of the PEplus protective earth rails. The wider width prevents the protective-conductor (PE) current collector head from inadvertently contacting a phase...

Open the catalog to page 11

Curves Rail Curves The conductor rail system is designed for the on-site preparation of curves or curved sections. For larger radii, the profile can be manually adjusted to the contour of the carrier rail during installation in the hanger clamps. A manual bending device is used for smaller bends or high system speeds. Rail Curves for PE plus Protective Conductors with Rail Polarity Protection For PEplus bends with radii less than 1500 mm, the rail profile has to be modified with incisions, or the rail component already prepared at the factory has to be used (see below). The PEplus rail with...

Open the catalog to page 12All Conductix-Wampfler catalogs and technical brochures

-

CGR Slip Rings

6 Pages

-

WirelessCharger 3.0

20 Pages

-

Jay RadioSafe

6 Pages

-

Product Overview Motorized Reels

28 Pages

-

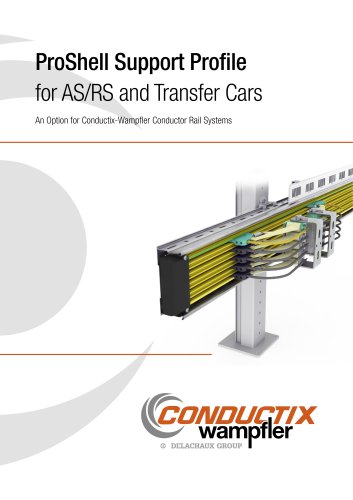

Product Overview Conductor Rails

20 Pages

-

Product Overview Cables

16 Pages

-

Motor Driven Reels - MAG Drive

20 Pages

-

Industrial Spring Reels

28 Pages

-

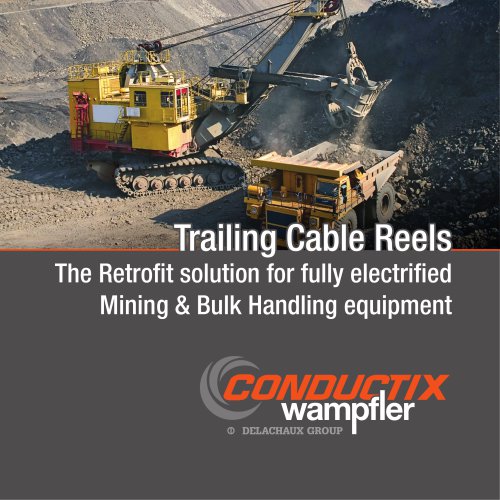

Trailing Cable Reels

4 Pages

-

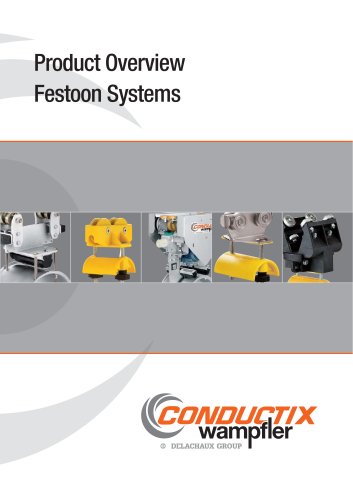

Festoon Systems for I-Beams

36 Pages

-

LM Series

6 Pages

-

Drive-In

4 Pages

-

Jib Booms Program 0420

24 Pages

-

Fiber optic Spring Reels

2 Pages