Website:

Conductix-Wampfler

Website:

Conductix-Wampfler

Group: Delachaux Group

Catalog excerpts

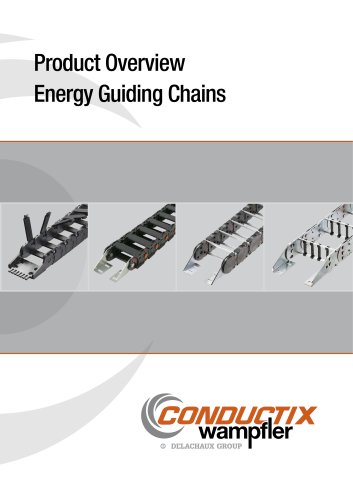

Energy Guiding Chains for RMG and RTG Crane Trolleys

Open the catalog to page 1

LM Series – Key Benefits Specifically developed for RMG and RTG applications Aluminum frame stays for minimal friction between the chain and the cables LM52: Especially for applications with small additional loads where nevertheless a robust design is required LM82: Extremely robust design for applications with high additional loads and for long travel ways Chain cross section with special dividers to improve the stability for chains with larger chain widths Low maintenance Replaceable sliding shoes to reduce the sliding friction coefficient and to extend the chain life time Fixed lateral...

Open the catalog to page 2

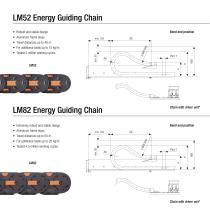

LM52 Energy Guiding Chain Bend end position ÜB • Robust and stable design • Aluminum frame stays • Travel distances up to 40 m • For additional loads up to 15 kg/m • Tested 2 million working cycles LM82 Energy Guiding Chain Chain with driver unit* • Extremely robust and stable design • Aluminum frame stays • Travel distances up to 50 m • For additional loads up to 20 kg/m • Tested 4.5 million working cycles

Open the catalog to page 3

Max. travel distance (with guiding channel): 40 m Max. travel speed: 180 m/min Acceleration: 1 m/s² Max. additional load: 15 kg/m Temperature range: -25°C to +70°C Standard material: Polyamide, black Chain cross section Sliding shoes available for long travel distances Max. travel distance (with guiding channel): 50 m Max. travel speed: 180 m/min Acceleration: 1 m/s² Max. additional load: 20 kg/m Temperature range: -25°C to +70°C Standard material: Polyamide, black Chain cross section Sliding shoes available for long travel dista

Open the catalog to page 4

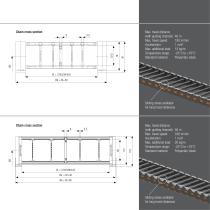

Link height: Chain internal width Bi: (other internal widths on request) Chain pitch: Bending radius KR: Number of backward bending radius links for lower driver connection: Backward bending radius RKR: Height of chain bend H: Installation height HEB (H+50): Driver connecting height H`: Bend overhang ÜB: * When using a driver unit, the connecting height H` to the chain must be lowered – technical design available on request. Link height: Chain internal width Bi: (other internal widths on request) Chain pitch: Bending radius KR: Number of backward bending radius links for lower driver...

Open the catalog to page 5

© Conductix-Wampfler I 2015 Subject to technical modifications without prior notice www.conductix.com Conductix-Wampfler GmbH Rheinstrasse 27+33 79576 Weil am Rhein Germany Customer Support Phone +49 (0) 7621 662-222 Phone Fax info.de@conductix.com www.conductix.com

Open the catalog to page 6All Conductix-Wampfler catalogs and technical brochures

-

CGR Slip Rings

6 Pages

-

WirelessCharger 3.0

20 Pages

-

Jay RadioSafe

6 Pages

-

Product Overview Motorized Reels

28 Pages

-

Product Overview Conductor Rails

20 Pages

-

Product Overview Cables

16 Pages

-

Motor Driven Reels - MAG Drive

20 Pages

-

Industrial Spring Reels

28 Pages

-

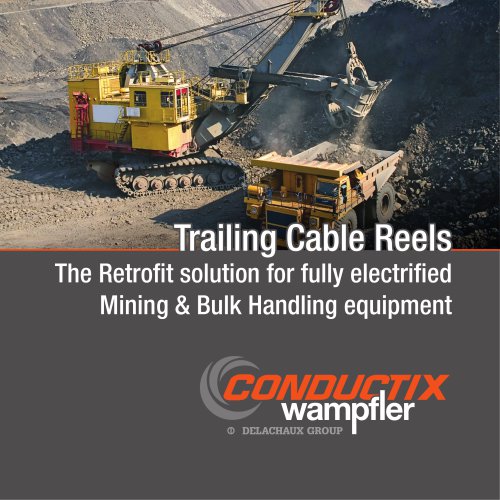

Trailing Cable Reels

4 Pages

-

Festoon Systems for I-Beams

36 Pages

-

Drive-In

4 Pages

-

Jib Booms Program 0420

24 Pages

-

Fiber optic Spring Reels

2 Pages