Website:

Conductix-Wampfler

Website:

Conductix-Wampfler

Group: Delachaux Group

Catalog excerpts

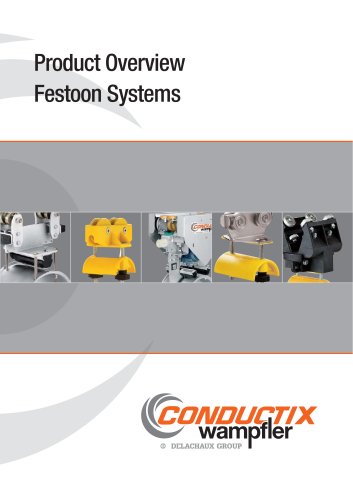

Festoon Systems for I-Beams Program 0365/0370/0375 ©JNDUQTIX wampfler

Open the catalog to page 1

Contents System Arrangement Festoon System for Flat and Round Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Cable Trolleys for Round Cables Program 0365 Single Layer Cable Trolleys with Main Rollers ø 112 mm / ø 125 mm...

Open the catalog to page 3

1. Towing trolley / towing clamp A festoon system consists of the following components: • 1 x end clamp • X x cable trolley • 1 x towing clamp or alternatively 1 x towing trolley • Cable trolleys and towing trolleys require a running gear, which must be selected in addition to the trolley under part • Cable trolleys and towing trolleys are set to fit the exact track beam, in all cases the track beam must be specified • The system components can be equipped with one additional cable support depending on the program. To ensure optimum operation of the system, depending upon the application,...

Open the catalog to page 4

Technical details Cable supports bolted to the center plate, lateral-loading and reinforced Clamping bar V-clamping (divided) Buffers double-sided cellular buffer Travel speed max. 11 300 m/min 2) Cable trolley underpart and running gear hot-dipped galvanized steel Fasteners stainless steel 1) depending on roller size/ roller material 2) together with motorized trolleys A cable trolley underpart with the following dimensions shall be used: • Support diameter: da = 460 mm • Clamping width: b2 = 125 mm; • Clamping heigth: s = 46 mm Order No. 036523-93 (chosen from catalog page...

Open the catalog to page 5

Cable trolley Cable Trolley Underpart without Running Gear Order No. Notes on the directional installation of the festoon systems towing trolley at the cranes catenary trolley: Please reference the system drawing in your order documentation. In general, it is critical to point out: The buffer unit of the towing trolley mounted to the cranes catenary trolley is oriented so that the buffer unit is pointing toward the towing unit of the festoon system. Towing trolley for catenary trolley Notes • The table only refers to the cable trolley or the towing trolley under part • The running gear must...

Open the catalog to page 6

End clamp Drilling template end clamp Towing clamp Order No. Main Roller 0 d [mm] Material Bandage Weight approx. [kg] Preference I-Beam Code Range I-Beams Tapered-Flange I-Beam Code Type HMG with cylindrical main rollers, horizontal guide rollers at the beam center web and anti-lift rollers Vulkollan Adiprene 0022 Type HMP with cylindrical main rollers, horizontal guide rollers at the beam center web and anti-lift plate Vulkollan Adiprene 0022 Notes / design • Main roller 0 112 mm: anti-lift roller 0 63 mm made of stainless steel, horizontal guide roller 0 63 mm with Vulkollan...

Open the catalog to page 7

Technical details Cable supports bolted to the center plate, lateral-loading and reinforced Clamping bar V-clamping (divided) Buffers double-sided cellular buffer Travel speed max. 11 210 m/min Cable trolley underpart and running gear hot-dipped galvanized steel Fasteners stainless steel 1) depending on roller size/ roller material A cable trolley underpart with the following dimensions shall be used: • Support diameter:: da / da2 = 360 / 260 mm • Clamping width: b2 = 200 mm; • Clamping heigth: s / s2 = 85 / 40 mm Order No. 037023- 8666 (chosen from catalog page 8) The...

Open the catalog to page 9

Cable trolley Cable Trolley Underpa without Running Gear Order No. Notes • The table only refers to the cable trolley or the towing trolley under part • The running gear must be selected and added. (see page 9 in this catalog) • The cable trolley is always equipped with an additional support

Open the catalog to page 10

Drilling template end clamp Drilling template towing clamp Towing clamp Selection of Running Gear Running Gear Type HMG with cylindrical main rollers, horizontal guide rollers at the beam center web and anti-lift rollers Notes / design • Main roller 0 125 mm: anti-lift roller 0 63 mm made of stainless steel, horizontal guide roller 0 80 mm with Vulkollan respectively Adiprene bandage • Main roller 0 160 mm: anti-lift roller 0 80 mm made of stainless steel, horizontal guide roller 0 112 mm with Vulkollan respectively Adiprene bandage • The rollers are equipped with precision ball bearings...

Open the catalog to page 11

Ordering Example Technical details Cable supports bolted to the center plate, lateral-loading and reinforced Clamping bar V-clamping (divided) Buffers double-sided cellular buffer Travel speed max. 11 300 m/min 2) Cable trolley underpart and running gear hot-dipped galvanized steel Fasteners stainless steel 1) depending on roller size/ roller material 2) together with motorized trolleys A cable trolley underpart with the following dimensions shall be used: • Support diameter: da / da2 = 460 / 360 mm • Clamping width: b2 = 250 mm; • Clamping heigth: s / s2 = 46 / 36 mm Order...

Open the catalog to page 13

Cable trolley Cable Trolley Underpart without Running Gear Order No.

Open the catalog to page 14

Selection of Running Gear Running Gear Type HMG with cylindrical main rollers, horizontal guide rollers at the beam center web and anti-lift rollers Notes / design • Main roller 0 125 mm: anti-lift roller 0 63 mm made of stainless steel, horizontal guide roller 0 80 mm with Vulkollan respectively Adiprene bandage • Main roller 0 160 mm: anti-lift roller 0 80 mm made of stainless steel, horizontal guide roller 0 112 mm with Vulkollan respectively Adiprene bandage • The rollers are equipped with precision ball bearings and additional sealing disks (2RS1), the ball bearings are lifetime...

Open the catalog to page 15

Notes • We recommend the installation of towing ropes for a speed from 50 m/min or a travel distance > 30 m • The towing ropes are PVC-coated for a better protection against corrosion and to prevent the cables from damage • For the calculation of the lengths please refer to our Engineering Guideline KAT0300-0101 • In case of order please state the lengths LZug of the respective towing ropes Technical details • Shock cord: rubber with plastic plait • Console: hot-dipped galvanized steel • Fasteners: stainless steel Notes • We recommend the installation of damping devices for high speed...

Open the catalog to page 17All Conductix-Wampfler catalogs and technical brochures

-

CGR Slip Rings

6 Pages

-

WirelessCharger 3.0

20 Pages

-

Jay RadioSafe

6 Pages

-

Product Overview Motorized Reels

28 Pages

-

Product Overview Conductor Rails

20 Pages

-

Product Overview Cables

16 Pages

-

Motor Driven Reels - MAG Drive

20 Pages

-

Industrial Spring Reels

28 Pages

-

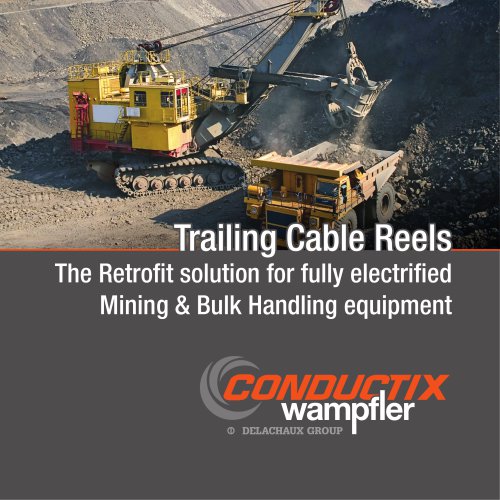

Trailing Cable Reels

4 Pages

-

Festoon Systems for I-Beams

36 Pages

-

LM Series

6 Pages

-

Drive-In

4 Pages

-

Jib Booms Program 0420

24 Pages

-

Fiber optic Spring Reels

2 Pages