Website:

Conair

Website:

Conair

Catalog excerpts

GRAVIMETRIC BATCH BLENDERS - MEDLINE® ACCURATE GRAVIMETRIC BLENDING IN SMALL BATCHES Get accurate blends, better mixing, faster material changes and increased profits with Conair’s MedLine® TrueBlend Series Blenders. Steep-sided compartments allow resin to flow evenly through vertical dispense valves into the weigh chamber. Efficient mixing fully integrates all recipe ingredients. Enclosed cabinet design assures clean operation without pellet spillage. MedLine blenders reduce downtime for cleaning out particulate with features such as quick access material compartment bins, a hinged chassis access door and removable components in the mixing chamber. The MedLine® TrueBlend TB100 series blenders offer small extruders and medium tonnage injection molding machines a superior way to blend color and additives centrally or at the throat of the processing machine. The blender dispenses up to four materials from respective material compartments into a common weigh chamber. The control determines the correct weight of each ingredient based on setpoints entered on the touch screen display. Up to 1000 recipes and 250 resin names can be entered and stored in the processor. Unique fast-acting “no stick” vertical valves control the amount of material dispensed. All dispense valves use two-way air cylinders, to ensure positive operation. Conair’s MedLine blenders are designed to work in cleanroom environments with Conair’s MedLine range of other medical grade solutions in extrusion, conveying, heat transfer, and drying. ■ Calibrated to ISO standards The MedLine TB100 is calibrated to ISO standards, perfect for any cleanroom application. ■ Blend accuracy to 1/2 of 1% Colorant and/or additive weights are held to within 0.5% of setting. A selectable Precision Additive™ feature is also available for additives. The microprocessor control automatically calibrates after every cycle and compensates for variations in dispense method, resin bulk density or particle geometry. ■ Easy-to-use control Intuitive 5.7 inch LCD touch screen control with full color graphics allows quick and easy setup of blender setpoints. All setpoints are displayed simultaneously. Enter the percentages of the blend on the touch screen display and the blender does the rest. The system automatically weighs the recipe ingredients in the proper sequence and maintains the correct blend relationship. Any position can be identified as one of the four material type selections adding flexibility to your application setup. ■ Convenient, easy clean out Easy access to all material contact points for fast and safe cleaning during color or resin changes. The blender features a built-in material shutoff valve below the mixing chamber, which can be replaced with the automatic flow control valve for remote and central blending applications. 200 West Kensinger Drive • Cranberry Township, PA 16066 • 724-584-5500 • fax 724-584-5299 • www.conairgroup.com

Open the catalog to page 1

TPBM002-1 1 15 GRAVIMETRIC BATCH BLENDERS - MEDLINE® Intuitive, SB-2 touch screen control offers the industry’s best multi-component accuracy This easy-to-use touch screen control allows for fast setup of blender setpoints and automatically weighs recipe ingredients in the proper sequence to maintain correct blend relationship. Any position can be identified as one of the four material type selections adding flexibility to your application setup. SmartBlendTM SB-2 Premium touch screen control offers these high performance functions to target the unique process needs of molders and...

Open the catalog to page 2

GRAVIMETRIC BATCH BLENDERS - MEDLINE FEATURES Simple and quick cleanout Clear away any particulate quickly with the MedLine TrueBlend’s easy access to all material contact points. Material compartment access doors, removable weigh bin, mix agitator and mix chamber liner all allow quick, efficient cleaning. OPTIONS TB reports Used to track and document material usage, alarms, batch and shift reports and recipes. See TrueBlend Reporting Software and ControlWorks specification sheets. Optional floor stand design MedLine blenders install easily to this floor stand, which is equipped with a...

Open the catalog to page 3

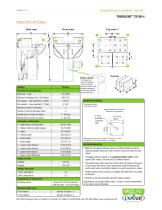

TPBM002-1 1 15 GRAVIMETRIC BATCH BLENDERS - MEDLINE® SPECIFICATIONS Side view 4-C Top view MOUNTING INTERFACE Dimensions shown in inches and {mm}. Mounting bolt hole size (4 holes) 7/16 inch {11.0 mm}. Predrilled 5 x 5 mounting pattern as standard. SPECIFICATION NOTES 200 West Kensinger Drive • Cranberry Township, PA 16066 • 724-584-5500 • fax 724-584-5299 • www.conairgroup.com * Maximum throughput rates are based on 35 lb/ft3 pelletized material, using all standard valve sizes. Use of reducer inserts will lower the rate shown. Throughput rates are based on a 4-position blender recipe of...

Open the catalog to page 4All Conair catalogs and technical brochures

-

5000 Blender

4 Pages

-

CH SERIES INSULATED HOPPERS

4 Pages

-

HTC MODELS 600-5000

2 Pages

-

GASTRAC PROCESS AIR HEATER

2 Pages

-

MedLine® TrueFeed

4 Pages

-

MedLine

4 Pages

-

TrueRate™

3 Pages

-

TrueWeigh

6 Pages

-

INTERMIXER

2 Pages

-

PET PREFORM SYSTEMS

12 Pages

-

TRUEBLEND ™ TB45-4

4 Pages

-

Economy cooling tank

2 Pages

-

Heat Exchangers

11 Pages

-

medical tubing products

4 Pages

-

Water Pump Motors

1 Pages

-

Tower Isolation (PFT) Series

2 Pages

-

Film Scrap Granulators

4 Pages

-

Trim Pick-Up Inducers

2 Pages

-

ScrapSaver Fluff Feeder

2 Pages

-

TrueWeigh Continuous Blender

6 Pages

-

TrueWeigh Line Manager

2 Pages

-

TrueWeigh Hopper

2 Pages

-

Dump Table

2 Pages

-

ATC Series Coilers

2 Pages

-

CPC Series

4 Pages

-

Medline

6 Pages

-

TPC Planetary Cutter

2 Pages

-

CSC Series Cleated Puller

2 Pages

-

Precision Series Belt Puller

2 Pages

-

MCB Series Cooling Tank

2 Pages

-

MEDVAC TANKS

4 Pages

-

RESIN LEVEL DISPLAY

2 Pages

-

HTR series

4 Pages

-

VTR

4 Pages

-

TW-V

4 Pages

-

TW-S

4 Pages

-

TW-P

4 Pages

-

TrueWeigh Control TWC1-12

2 Pages

-

Equipment catalog

435 Pages

-

Parts and accessories

262 Pages

-

TAC series

2 Pages

-

CLEAN ROOM READY

6 Pages

-

WELDED SILOS

2 Pages

-

TrueWeigh Continous Blenders

6 Pages

-

TRUEFEED LIQUID FEEDER

2 Pages

-

Gaylord Tilters

2 Pages

-

Surge Bins, In-Plant

4 Pages

-

MT VACUUM SIZING TANKS

4 Pages

-

CBW GRANULATORS

2 Pages

-

Tube Loader (TLM)

2 Pages

-

HTMP SERIES

4 Pages

-

NC GRANULATORS

2 Pages

-

NCM GRANULATORS

2 Pages

-

TrueBlend? TB45

4 Pages

-

W Dryers (150-400)

4 Pages

-

W Dryers (15-100)

4 Pages

-

MICROWHEEL DRYERS

4 Pages

-

CAML-EVB Evacuation System

2 Pages

-

SCRAPSAVER (SSM)

2 Pages

-

MDCW (15-100)

4 Pages

-

THERMOLATOR® (TW) SERIES

4 Pages

-

MDCW (150-200)

4 Pages

-

PTFG

4 Pages

-

CFC series

2 Pages

-

EP2

8 Pages

-

PTSS 0450

4 Pages

-

EP1

6 Pages

-

TrueBlend? High Heat

4 Pages

-

TrueBlend? TB250

4 Pages

-

SlimLine (SL) Dryer

4 Pages

-

FLX-128

4 Pages

-

Powder Loader (PL)

2 Pages

-

Access? (AR) Receivers

4 Pages

-

CAML-EVG Evacuation System

2 Pages

-

Access? (AL) Loaders

4 Pages

-

Mobile Surge Bins

2 Pages

-

Bolted Silos

2 Pages

-

Spiral Aluminum Silos

2 Pages

-

GasTrac Process Air Heater

2 Pages

-

HTC Temperature Controller

2 Pages

-

Thermolator® vacuTrac

4 Pages

-

BP Series Belt Pullers

2 Pages

-

Pump Tank, Polymer

4 Pages

-

WSB/GB Retrofit Control

2 Pages

-

DM3-i Drying Monitor

2 Pages

-

ResinWorks System

4 Pages

-

BFS/BFH Metering Feeders

4 Pages

-

CH Hoppers

4 Pages

-

FL Filterless Receiver

2 Pages

-

Vacuum Railcar Unloading

2 Pages

-

Tube Loader (TLA)

2 Pages

-

FLX Loading Control

2 Pages

-

Silos, Spiral Steel

2 Pages

-

Dust Collectors (DC)

2 Pages

-

ELC Series Controls

4 Pages

-

MDCW Carousel Plus Dryer

115 Pages