Catalog excerpts

TENSIONLESS WINDING WITH AUTOMATIC CUT AND TRANSFER ATC dual spindle coilers wind small flexible extrusions with littleto-no friction or winding tension. This eliminates deformities in delicate products making it ideal for extrusions such as medical tubing, small tube, filled cords and small flexible profiles. The fully automated process transfers the product to the new reel without operator involvement or process disruption and effectively increases line speed and performance during changeover. (Shown without full enclosure) SERVO PRECISION FOR HIGHEST PERFORMANCE Automatic Cut and Transfer Coilers are ■ Best accuracy with servo control the perfect choice for tensionless windTurret rotation, traverse and spindle speed are all servo driven. This provides the ing of small diameter flexible tubing. ultimate in speed and positioning control for error-free performance, exceptionally high repeatability and minimal product tension throughout high speed coilTension control is accomplished through ing and cut/transfer. Finished spools require no ‘dial-in’ for product changeover. a non-contact sonic loop detector communicating with a PLC to automatically ■ Distortion-free product adjust coil speed and traverse. Typical Minimum tension is achieved by an advanced control algorithm that calculates tube diameters are 0.085 inch to 0.50 each successive wrap diameter to adjust coil speed and traverse relative to the inch {2.16 to 12.7 mm}. Tubes as small puller speed. This allows the sonic loop control to perform as a fine-trim device as 0.020 inch {0.5 mm} can be accomand ensures accurate, distortion-free, error-free lay of each wrap. The following modated with a specialized minimal circuit allows automated ramp-up of the winder synchronously with the line at tension trim control. Automatic turret startup. changeover is accomplished when the set amount of footage for the coil is ■ Recipes cut operator variability/error reached. Every operating input parameter can be saved as a recipe for repeatable prodThe system comes complete with collapsible core assemblies or spools and can optionally accept customer supplied spools. All winder components that come into contact with the tube are made from stainless steel or are hard coat anodized. uct and process consistency. This includes coil speed changes during cut and transfer, traverse speed for accurate lay and turret speed during changeover to avoid product touching the floo

Open the catalog to page 1

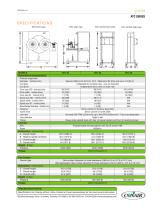

Trim control front view Trim control side view MODELS Performance characteristics Product range tube diameter inches {mm} Coil type Coil drive Core size OD inches {mm} Core width inches {mm} Core size ID inches {mm} Spool size OD inches {mm} Spool width inches {mm} Spool size ID inches {mm} Spool flange thickness inches {mm} Traverse Turret drive Line rate Line direction Frame Controls PLC Panel Dimensions inches {mm} A - Overall height B - Height to spindle centerline C - Overall length D - Overall width Weight lb {kg} Shipping Voltage Trim Control Dancer type Dimensions inches {mm} E -...

Open the catalog to page 2All Conair catalogs and technical brochures

-

5000 Blender

4 Pages

-

CH SERIES INSULATED HOPPERS

4 Pages

-

HTC MODELS 600-5000

2 Pages

-

GASTRAC PROCESS AIR HEATER

2 Pages

-

MedLine® TrueFeed

4 Pages

-

MedLine

4 Pages

-

TrueRate™

3 Pages

-

TrueWeigh

6 Pages

-

INTERMIXER

2 Pages

-

PET PREFORM SYSTEMS

12 Pages

-

TRUEBLEND ™ TB45-4

4 Pages

-

TRUEBLEND ™ TB100-4

4 Pages

-

Economy cooling tank

2 Pages

-

Heat Exchangers

11 Pages

-

medical tubing products

4 Pages

-

Water Pump Motors

1 Pages

-

Tower Isolation (PFT) Series

2 Pages

-

Film Scrap Granulators

4 Pages

-

Trim Pick-Up Inducers

2 Pages

-

ScrapSaver Fluff Feeder

2 Pages

-

TrueWeigh Continuous Blender

6 Pages

-

TrueWeigh Line Manager

2 Pages

-

TrueWeigh Hopper

2 Pages

-

Dump Table

2 Pages

-

CPC Series

4 Pages

-

Medline

6 Pages

-

TPC Planetary Cutter

2 Pages

-

CSC Series Cleated Puller

2 Pages

-

Precision Series Belt Puller

2 Pages

-

MCB Series Cooling Tank

2 Pages

-

MEDVAC TANKS

4 Pages

-

RESIN LEVEL DISPLAY

2 Pages

-

HTR series

4 Pages

-

VTR

4 Pages

-

TW-V

4 Pages

-

TW-S

4 Pages

-

TW-P

4 Pages

-

TrueWeigh Control TWC1-12

2 Pages

-

Equipment catalog

435 Pages

-

Parts and accessories

262 Pages

-

TAC series

2 Pages

-

CLEAN ROOM READY

6 Pages

-

WELDED SILOS

2 Pages

-

TrueWeigh Continous Blenders

6 Pages

-

TRUEFEED LIQUID FEEDER

2 Pages

-

Gaylord Tilters

2 Pages

-

Surge Bins, In-Plant

4 Pages

-

MT VACUUM SIZING TANKS

4 Pages

-

CBW GRANULATORS

2 Pages

-

Tube Loader (TLM)

2 Pages

-

HTMP SERIES

4 Pages

-

NC GRANULATORS

2 Pages

-

NCM GRANULATORS

2 Pages

-

TrueBlend? TB45

4 Pages

-

W Dryers (150-400)

4 Pages

-

W Dryers (15-100)

4 Pages

-

MICROWHEEL DRYERS

4 Pages

-

CAML-EVB Evacuation System

2 Pages

-

SCRAPSAVER (SSM)

2 Pages

-

MDCW (15-100)

4 Pages

-

THERMOLATOR® (TW) SERIES

4 Pages

-

MDCW (150-200)

4 Pages

-

PTFG

4 Pages

-

CFC series

2 Pages

-

EP2

8 Pages

-

PTSS 0450

4 Pages

-

EP1

6 Pages

-

TrueBlend? High Heat

4 Pages

-

TrueBlend? TB250

4 Pages

-

SlimLine (SL) Dryer

4 Pages

-

FLX-128

4 Pages

-

Powder Loader (PL)

2 Pages

-

Access? (AR) Receivers

4 Pages

-

CAML-EVG Evacuation System

2 Pages

-

Access? (AL) Loaders

4 Pages

-

Mobile Surge Bins

2 Pages

-

Bolted Silos

2 Pages

-

Spiral Aluminum Silos

2 Pages

-

GasTrac Process Air Heater

2 Pages

-

HTC Temperature Controller

2 Pages

-

Thermolator® vacuTrac

4 Pages

-

BP Series Belt Pullers

2 Pages

-

Pump Tank, Polymer

4 Pages

-

WSB/GB Retrofit Control

2 Pages

-

DM3-i Drying Monitor

2 Pages

-

ResinWorks System

4 Pages

-

BFS/BFH Metering Feeders

4 Pages

-

CH Hoppers

4 Pages

-

FL Filterless Receiver

2 Pages

-

Vacuum Railcar Unloading

2 Pages

-

Tube Loader (TLA)

2 Pages

-

FLX Loading Control

2 Pages

-

Silos, Spiral Steel

2 Pages

-

Dust Collectors (DC)

2 Pages

-

ELC Series Controls

4 Pages

-

MDCW Carousel Plus Dryer

115 Pages