Catalog excerpts

Oil-Free Rotary Screw Compressors Fixed & Regulated Speed (RS) Innovative oil-free compressed air technologies

Open the catalog to page 1

Air purity that meets the most stringent hygienic standards Outstanding reliability for demanding applications The two-stage oil-free screw compressor range has been designed with a focus on operational safety in demanding applications. The innovative clear construction delivers state-of-the-art performance, in-depth control and outstanding reliability. The sophisticated Delcos XL controller protects your investment by continuously monitoring operational parameters. CompAir's own designed and manufactured airend works at constant low temperature levels and lowers the compressor’s lifecycle...

Open the catalog to page 2

CompAir’s commitment to providing the purest, highest quality compressed air, through the development of innovative products, delivers world-class solutions. MANUFACTURE Engineering excellence Compressors are more than just a financial investment, they are a key component to ensuring that manufacturers, processors and operators receive consistent, high quality, low cost air. The screw compression element is the heart of the compressor and therefore CompAir keeps the design and manufacture in-house, using the latest CNC rotor grinding machinery, coupled with online laser technology. Combined...

Open the catalog to page 3

Innovative oil-free design concept Choose the D-Series and eliminate your risks You may have no choice over the quality of the compressed air used in your process – it just has to be absolutely contaminant free. CompAir have been designing, manufacturing and supplying oil-free compressors for more than 100 years. The award winning D-Series has been continuously developed and achieves cutting edge performance and efficiency. ✓ Premium efficiency two stage airend design ✓ Unique closed cooling water circuit for airend cooling ✓ High quality IE 3 electric motor, optional IE 4 ✓ Efficient motor...

Open the catalog to page 4

State-of-the-art performance - through high efficiency components, low pressure losses, low temperatures and economical control. High output two stage airend design • 00% oil-free, near 1 isothermal compression • igh reliability thanks to H constant low temperatures Excellent cooling performance • Optimum motor cooling Guaranteed efficiency with IE3 electric motor • losed cooling water circuit for airend cooling C - For constant low temperature levels - Avoids pollution - Less gearboxes required • E4 electric motor optionally available I • Level regulated electronic condensate drain •...

Open the catalog to page 5

Perfect control – Perfect performance Delcos XL innovative touch screen compressor controller The Delcos XL with its high resolution touch screen display is extremely user-friendly and self-explanatory. All functions are clearly structured in five main menus and are intuitively visual. The multilingual Delcos XL control system ensures reliable operation and protects your investment by continuously monitoring the operational parameters, which is essential for reducing your running costs. Features & functions Trend diagrams With the ability to display detailed system analysis in the form of...

Open the catalog to page 6

Regulated Speed Compressors Tried and tested inverter concept Regulated speed compressors from CompAir can efficiently and reliably handle the varying air demand found in most plant air systems. • Integrated in the electric cabinet The annual cost of ownership can be significantly reduced using regulated speed technology. • Ensures high availability and long-life CompAir RS features are your benefits 10% A typical fixed speed screw compressor • Maximum reliability from optimised cooling system Maintenance and Service Costs The D-RS Series products are designed to obtain the greatest...

Open the catalog to page 7

SmartAir Master compressed air management system Energy management is crucial for all compressed air users, as the highest cost factor of a compressor is the energy to run it. Over a period of five years, energy accounts for typically 80% of the total costs. Compressed air systems typically comprise of multiple compressors delivering air to a common distribution system. The combined capacity of those machines is generally greater than the maximum site demand. With CompAir's advanced demand responsive sequencer SmartAir Master, the efficiency of the compressor stations with up to twelve...

Open the catalog to page 8

Heat recovery A modern production system and process demands increasing levels of air quality. A CompAir compressed air system utilising the latest technology provides an energy efficient solution at lowest life cycle costs. The heat generated during compression is paid for as part of the process, then paid for again during removal by way of cooling fans. Instead of simply removing the heat, it can be used to generate free hot process water or hot water heating systems by utilising a high efficiency, factory fitted oil to water heat exchanger. Upgrade your compressed air system with heat...

Open the catalog to page 9

Protect your investment Compact design – easy installation The small footprint reduces the space required for installation. Easy servicing The design of these packages ensures that the service points are readily accessible. The enclosure side doors are hinged and removable to allow complete access to all service points. The reduced number of moving parts further lowers the maintenance costs. CompAir genuine spare parts PureCARE - Six years extended warranty free of charge Specifically developed to support our oil-free product range, the CompAir PureCARE service programmes go beyond...

Open the catalog to page 10

CompAir D-Series - Technical Data D75 – D315 Fixed Speed Compressor Model Cooling Method Air Water Air Water Air Water Air Water Air Water Air Water Air Water Air Water Air Water D110RS – D315RS Regulated Speed Compressor Model Cooling Method Air Water Air Water Air Water Air Water Air Water Air Water Air Water Air Water Air Water Air Water Water D ata measured and stated in accordance with ISO 1217, Edition 4, Annex C and Annex E and the following conditions: Air Intake Pressure 1 bar a, Air Intake Temperature 20°C, Humidity 0 % (Dry). Noise Level at 70% Load 2] [dB(A)] 76 Measured in free...

Open the catalog to page 11All COMPAIR catalogs and technical brochures

-

Rotary Screw Compressors

8 Pages

-

C-Series - Portable Compressors

14 Pages

-

Oil-free compressors

16 Pages

-

DH Series - oil-free compessors

12 Pages

-

Compressed air dryers

4 Pages

-

AirInsite air audit

4 Pages

-

L160 - L250, RS compressors

4 Pages

-

L02 - L05 compressors

4 Pages

-

L23 - L29, RS compressors

8 Pages

-

L30 - L132, RS compresors

12 Pages

-

L07 - L22 Compressors

8 Pages

Archived catalogs

-

Hydrovane

13 Pages

-

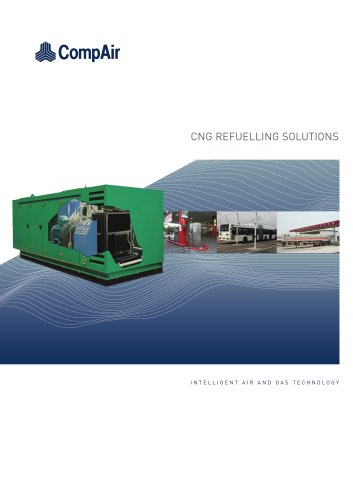

CNG REFUELLING SOLUTIONS

16 Pages