Catalog excerpts

Technical Specifications: H5450 & H5470Up to 350 bar g, 150 to 1658 m > 3 2 3 /h Up to 5075 lbf/in , 88 to 976 ft /minA range of boosters and compressors suitable for airand gases. The pressurised crankcase is suitable for inlet pressures up to 15 bar g and is particularly suitable for hazardous gas duties. For safe gas applications, inlet pressures can extend to a maximum of 100 bar g.With over 100 years of experience CompAircompressors set high quality standards in world-wide markets. Typical applications include compressed natural gas, air blast switch-gear, nitrogen boosting, electrolyser gas compression, seismic surveying, fibreboard pulp compression and many other industrial duties. Certain configurations permit the use of a membrane dehydrator that removes unwanted gas or water molecules from the gas stream by selective permeation through a hollow fibre membrane bundle. > H5450 Motor Driven Set Key Points: High pressure, multiple stage, air cooledcompressor modulesՕ Low maintenance, no special tools Electric motor or engine driveՕ Forced air interstage and final stage cooling forlow discharge temperatures Comprehensive range of safety features Օ World-wide installation and maintenance Both compressors are of an advanced designallowing cylinders and compression stages to beoptimised around inlet capacity requirements. This leads to reductions in power consumption, wear, discharge temperatures and an extension of serviceintervals Օ Extensive factory testing Well balanced compressor design, removing theneed for special foundations and increasing component lifeՕ Explosion proof and intrinsically safe installationto comply with national standards, where applicable Gas inlet filter and pressure regulator forboostersՕ Gas tight crankcase Individual compression stage separation withautomatic drainage and unloadingՕ Options for membrane drying and selective gasseparation >

Open the catalog to page 1

The H5450 and H5470 compressors have a range ofconfigurable cylinders that enable performance to be very closely matched to the required duty. In this manner the machines can be arranged with 1 to 5 stages using 3 to 6 cylinders. The crankcase may be pressurised up to 15 bar g whichpermits hazardous gas booster applications, where the crankcase is equalised to the suction pressure.For inert gases the units may be used with a maximum suctionpressure of 100 bar g, by use of a non-pressurised crankcase. Standard fittings > Air Cooled aftercooler > H5450 Motor Driven Set H5470 Base...

Open the catalog to page 2All COMPAIR catalogs and technical brochures

-

D series

12 Pages

-

Rotary Screw Compressors

8 Pages

-

C-Series - Portable Compressors

14 Pages

-

Oil-free compressors

16 Pages

-

DH Series - oil-free compessors

12 Pages

-

Compressed air dryers

4 Pages

-

AirInsite air audit

4 Pages

-

L160 - L250, RS compressors

4 Pages

-

L02 - L05 compressors

4 Pages

-

L23 - L29, RS compressors

8 Pages

-

L30 - L132, RS compresors

12 Pages

-

L07 - L22 Compressors

8 Pages

Archived catalogs

-

Hydrovane

13 Pages

-

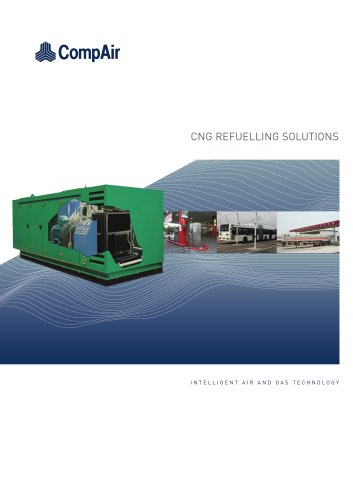

CNG REFUELLING SOLUTIONS

16 Pages