Catalog excerpts

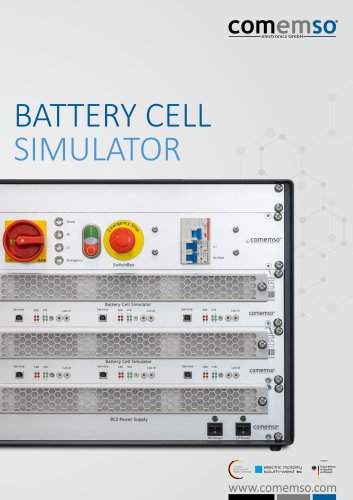

-electronics GmbH- BATTERY CELL SIMULATOR

Open the catalog to page 1

BATTERY CELL SIMULATOR THE VIRTUAL BATTERY The comemso battery cell simulator – the all-in-one battery management system test and development solution for (mobile) energy storage systems.

Open the catalog to page 2

BATTERY CELL SIMULATOR BATTERY CELLS NEED CONSTANT MONITORING Electromobility is growing at a tremendous rate worldwide. For today’s mobile energy storage systems, that means they not only have to deliver high performance, they also need to ensure safe, reliable operation. Doing so requires constantly monitoring the voltage and temperature of every single battery cell. This is done with a special electronic monitoring system called the cell management controller (CMC). Cell module Cell Management Controller (CMC) Individual battery cells are module A combined into cell Cell modules, and...

Open the catalog to page 3

BATTERY CELL SIMULATOR agement System Cell Management Controller (CMC) Cell Management Controller (CMC) The battery management system (BMS) includes the battery management unit (BMU) and all cell Cell Management Controller (CMC) management controllers (Fig. 2). The BMU is the central control unit for battery modules such as those Zellmodul A agement System used to drive electric vehicles or all other kinds of energy storage systems. It acts as the “brain” Zellmodul C Cell Management Controller (CMC) all of the information collected by the where battery monitoring systems comes together....

Open the catalog to page 4

Ba�ery Management Unit (BMU) Cell Management Controller (CMC) BATTERY CELL SIMULATOR Cell Management Controller (CMC) VIRTUAL BATTERY CELLS individual cell modules can then be fed into the test bench or hardware-in-the-loop system (HiL system). The battery cells and temperature sensors from comemso emulate the real functionality so the BMS can be operated in the lab. In addition, fault simulation can be used to generate faulty system states so that Since the conditions for testing real batteries are dangerous, unreproducible and not automatable, the validation of battery management systems...

Open the catalog to page 5

BATTERY CELL SIMULATOR FOR THE HIGHEST STANDARDS A battery cell simulator (BCS) must be capable of performing functional verification for many different aspects of a modern BMS and needs to provide high-precision voltage regulation even at high balancing currents so that it can accurately emulate the state of charge of a battery cell. It also needs well-matched hardware and software controls for high accuracy, with lean control algorithms that allow no overshoots while ensuring equally dynamic and safe performance. measurements or the coulomb measurement. Depending on the selected version,...

Open the catalog to page 6

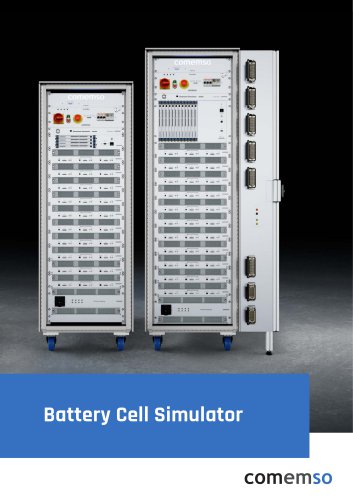

BATTERY CELL SIMULATOR COMEMSO BATTERY CELL SIMULATOR EXAMPLE WITH 96 VIRTUAL BATTERY CELLS Sophisticated safety concept with upgradable emergency stop circuit Test processes can be controlled with an external PC via CAN or EtherCAT Completely scalable systems with a wide range of features Each BCS module simulates 12 battery cells Battery management system Direct connection to the device under test (DUT) with cable sets for optimum precision and minimum interference High reliability and robust design with a 3-year guarantee LED status lights for quick status identification Sturdy castors...

Open the catalog to page 7

BATTERY CELL SIMULATOR INTEGRATED FAULT SIMULATION For best results and precise cell voltage, fault simulation is integrated in the BCS electronics of every cell. 1. DISCONNECTIONS Cable breaks in the connection between cells and BMS, material fatigue, etc. 2. SHORT CIRCUITS Faulty battery cells, cell control errors, defective electronic components, etc. 3. REVERSED POLARITY Cabling errors, reversed polarity in a cell, etc.

Open the catalog to page 8

BATTERY CELL SIMULATOR PRECISION IS INDISPENSABLE Measurement errors play a key role when the state of charge of the cells in a battery pack is being determined. Even inaccuracies of ±10 mV hamper active charge balancing. Cell measurement accuracy depends on the CMC’s voltage reference. The simplified discharge curve depicted here shows how important precise cell voltage measurement is. and follows a relatively linear path. In the illustration, 20% corresponds to approximately 3.25 V and 80% to approximately 3.6 V. Between 20% and 80% SoC (60%) there is thus a difference of 0.35 V (350 mV)....

Open the catalog to page 9

BATTERY CELL SIMULATOR THERMAL TEMPERATURE MONITORING Battery cells have a narrow range of working temperatures. Both the lifespan and cycle stability of a battery cell and the functional safety of a battery depend largely on the battery cell staying within this range. If the temperature exceeds a critical limit, a thermal runaway will result; the temperature increases drastically within milliseconds and the energy stored in the battery is released abruptly. Extremely high temperatures lead to a fire that is very difficult to extinguish with the usual means. To minimize the danger of a...

Open the catalog to page 10

Vector CANoe MathWorks MATLAB & Simulink PEAK-System PCAN-Explorer BATTERY CELL SIMULATOR Communica�on via your own CAN / EtherCAT* MATCHING HARDWARE AND SOFTWARE so�ware Service Vector CANoe dSpace ControlDesc MathWorks MATLAB & Simulink For rapid-deployment test systems with low implementation costs, comemso battery cell simulators support globally established software solutions. They can be quickly integrated in existing dSpace Na�onal Instruments OPAL-RT software test environments. The diagram below ControlDesc LabView ??? summarizes the numerous connectivity options. Battery Cell...

Open the catalog to page 11

BATTERY CELL SIMULATOR MODELING BATTERIES The state of charge is an important parameter for all battery-operated devices and plays a major role in energy storage systems. Its value is 100% when a battery is fully charged and decreases to 0% during discharging. Voltage measurements are generally used to determine the SoC value. With this method, a fully charged battery can be recognized by its higher voltage. However, the difference in voltage between the fully charged and discharged states is often only a few volts (V). An alternative is to determine the SoC value by current integration...

Open the catalog to page 12All Comemso electronics GmbH catalogs and technical brochures

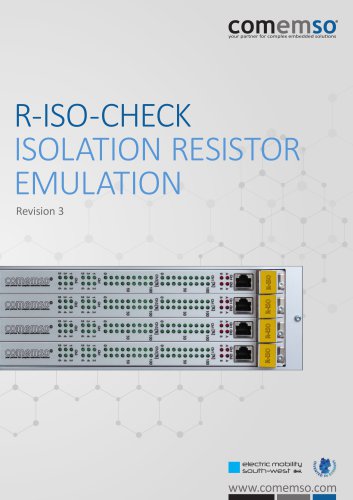

-

Battery Cell Simulator

11 Pages

-

Easy Chester Eichrecht

4 Pages

-

EVCA ComOnly Flex

4 Pages

-

Easy Chester

15 Pages