Website:

Comber Process Technology Srl

Website:

Comber Process Technology Srl

Group: Heinkel Drying and Separation Group

Catalog excerpts

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Termomix® Paddle Dryer Reactor TI 0053 E - 09/02

Open the catalog to page 1

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Termomix® Paddle Dryer / Reactor Termomix® Vacuum Paddle Dryer / Pressure Reactor • Economic, robust multipurpose machine for heavy industrial applications. • Suitable for use as mixer, reactor, precipitator and dryer, for vacuum and/or for pressure applications as per the requirements. • Calculation, design and manufacture in accordance with ASME pressure vessel code, Section VIII, with U-Stamp and/or Pressure Equipment Directive (PED)...

Open the catalog to page 2

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Termomix® Paddle Dryer / Reactor Termomix® TM 6000 paddle dryer / reactor with flat ends, 160 kW agitator drive, liquid lubricated double mechanical seals, dust filter with 12 m² filter area. Termomix® TM 12000 paddle dryer / reactor with dished ends, product wetted components mirror polished, liquid lubricated double mechanical seals. TI 0195 E - 09/06

Open the catalog to page 3

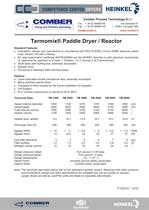

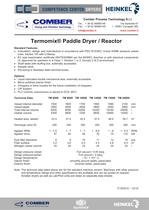

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Termomix® Paddle Dryer / Reactor Standard Features: • Calculation, design and manufacture in accordance with PED 97/23/EC or/and ASME pressure vessel code, Section VIII with U-Stamp. • EC type examination certificate 05ATEX0088X per the 94/9/EC directive or with electrical components UL approved for operation in a Class 1, Division 1 or 2, Groups C & D environment. • Shaft seals with stuffing box, externally accessible. • Sample valve. •...

Open the catalog to page 4

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Termomix® Paddle Dryer / Reactor Standard Features: • Calculation, design and manufacture in accordance with PED 97/23/EC or/and ASME pressure vessel code, Section VIII with U-Stamp. • EC type examination certificate 05ATEX0088X per the 94/9/EC directive or with electrical components UL approved for operation in a Class 1, Division 1 or 2, Groups C & D environment. • Shaft seals with stuffing box, externally accessible. • Sample valve. •...

Open the catalog to page 5

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Termomix® TM 4000 Paddle Dryer / Reactor Termomix® TM 4000 paddle dryer / reactor with dished ends, with ball valve for dry product discharge. With customer specified agitator shaft and agitator arms, both enlarged to increase the heating surface available. Shaft sealing with liquid lubricated double mechanical seals. Product wetted polished. components mirror TI 0267 E - 09/08

Open the catalog to page 6

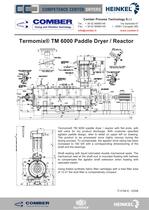

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Termomix® TM 6000 Paddle Dryer / Reactor Termomix® TM 6000 paddle dryer / reactor with flat ends, with ball valve for dry product discharge. With customer specified agitator paddle design, refer to detail on upper left on drawing. The product to be processed turns highly viscous during the drying process. To compensate, the agitator drive rating has been increased to 160 kW with a corresponding dimensioning of the shaft and the bearings. Shaft...

Open the catalog to page 7

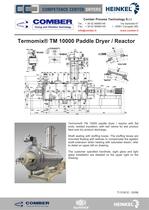

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Termomix® TM 10000 Paddle Dryer / Reactor Termomix® TM 10000 paddle dryer / reactor with flat ends, welded insulation, with ball valves for wet product feed and dry product discharge. Shaft sealing with stuffing boxes. The stuffing boxes are mounted floating with bellows to compensate the agitator shaft extension when heating with saturated steam, refer to detail on upper left on drawing. The customer specified handhole, sight glass and light...

Open the catalog to page 8

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Termomix® TM 10000 Paddle Dryer / Reactor Termomix® TM 10000 paddle dryer / reactor with flat ends, welded insulation, with ball valves for wet product feed and dry product discharge. Shaft sealing with stuffing boxes. The stuffing boxes are mounted floating with bellows to compensate the agitator shaft extension when heating with saturated steam, refer to detail on upper left on drawing. The customer specified handhole, sight glass and light...

Open the catalog to page 9

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Termomix® TM 12000 paddle dryer / reactor Termomix® TM 12000 paddle dryer / reactor with dished ends, liquid lubricated double mechanical seals, with CIP nozzles and spray balls for the cleaning of the vessel and dust filter interior in between individual batches, with ball valves for dry product discharge. External not product wetted components in painted carbon steel. TI 0266 E - 09/08

Open the catalog to page 10All Comber Process Technology Srl catalogs and technical brochures

-

Pharmadry Technology

12 Pages

-

Pressofiltro Pharma Technology

30 Pages

-

Controls

6 Pages

-

Comber Historic

2 Pages

-

Heel Removal

6 Pages

-

Peripherals

11 Pages

-

Microwave

6 Pages

-

Containment

6 Pages

-

Turbodry®

8 Pages

-

Condry®

8 Pages

-

Pharmadry®

12 Pages

-

Pilot Filter Dryer

12 Pages

-

Pressofiltro® Pharma

14 Pages

-

Pressofiltro® Chemical

6 Pages