Website:

Comber Process Technology Srl

Website:

Comber Process Technology Srl

Group: Heinkel Drying and Separation Group

Catalog excerpts

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® Vacuum Paddle Dryer TI 0052 E - 06/03

Open the catalog to page 1

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® Paddle Dryers Pharmadry® paddle dryer, left as vacuum dryer version, right in pressure proof version • In compliance with cGMP and FDA guidelines, also available in aseptic design: o Entirely welded agitator design, without any bolts, without pockets and with all edges rounded for good cleanability. o Agitator supported at the rear only, thus no couplings etc. in the product area. o Minimal build depth, thus very good accessibility...

Open the catalog to page 2

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® Paddle Dryers Cylindrical, horizontal vessel with flat welded rear cover and a hinged flat front door opening up over the entire vessel diameter. With the door open the internals of the machine are fully accessible for cleaning and inspection purposes. All surfaces in contact with the product such as the vessel, rear cover, front door, agitator and vapor filter are heated, providing very efficient heat exchange. To provide for good...

Open the catalog to page 3

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Pharmadry® Paddle Dryers Standard Features: • Calculation, design and manufacture in accordance with PED 97/23/EC or/and ASME pressure vessel code, Section VIII with U-Stamp as well as in compliance with cGMP and FDA guidelines. • EC type examination certificate 03ATEX0247X per the 94/9/EC directive or with electrical components UL approved for operation in a Class 1, Division 1 or 2, Groups C & D environment. • Double mechanical seal,...

Open the catalog to page 4

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Pharmadry® Paddle Dryers Standard Features: • Calculation, design and manufacture in accordance with PED 97/23/EC or/and ASME pressure vessel code, Section VIII with U-Stamp as well as in compliance with cGMP and FDA guidelines. • EC type examination certificate 03ATEX0247X per the 94/9/EC directive or with electrical components UL approved for operation in a Class 1, Division 1 or 2, Groups C & D environment. • Double mechanical seal,...

Open the catalog to page 5

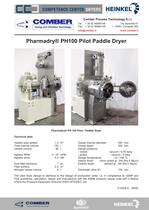

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® PH100 Pilot Paddle Dryer Pharmadry® PH 100 Pilot - Paddle Dryer Technical data: Heated area wetted: Total internal volume: Usable volume: Agitator RPM: Agitator drive: Dust filter elements: Filter surface: Nitrogen vessel volume: 1.3 m² 130 l 90 l 3 - 35 UPM 4.0 kW 1 pc. 0.2 m² 6 l Vessel internal diameter: 550 mm Vessel depth: 550 mm Design pressure: - vessel: vacuum / 0.45 barg - jacket: vacuum / 4 barg Design temperature: -10 / +99...

Open the catalog to page 6

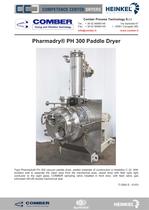

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® PH 300 Paddle Dryer Type Pharmadry® PH 300 vacuum paddle dryer, wetted materials of construction in Hastelloy C 22. With isolation wall to separate the clean area from the mechanical area, vessel lamp with fiber optic light conductor to the sight glass, COMBER sampling valve installed in front door, with feed valve, gas lubricated (lift-off) double mechanical seal. TI 0062 E - 01/03

Open the catalog to page 7

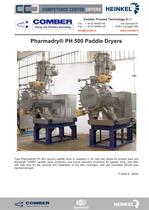

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® PH 500 Paddle Dryers Type Pharmadry® PH 500 vacuum paddle dryer in Hastelloy C 22, with ball valves for product feed and discharge, FAMAT sample valve, protection and sound reduction enclosure for agitator drive, dust filter with side door for the removal and installation of the filter cartridges, with gas lubricated (lift-off) type mechanical seal. TI 0084 E - 06/03

Open the catalog to page 8

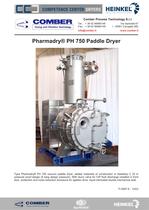

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® PH 750 Paddle Dryer Type Pharmadry® PH 750 vacuum paddle dryer, wetted materials of construction in Hastelloy C 22 in pressure proof design (6 barg design pressure). With slurry valve for CIP fluid discharge installed in front door, protection and noise reduction enclosure for agitator drive, liquid lubricated double mechanical seal. TI 0097 E - 12/03

Open the catalog to page 9

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® PH 1000 Paddle Dryer Type Pharmadry® PH 1000 vacuum paddle dryer, with ball valve for product feed, pivoting ball discharge valve, sight glass built into front door, protection and sound reduction enclosure for agitator drive, with gas lubricated (lift-off) double mechanical seal, dust filter with side door for the removal and reinstallation of the filter cartridges. TI 0214 E - 07/07

Open the catalog to page 10

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pharmadry® PH 2500 Paddle Dryer Type Pharmadry® PH 2500 vacuum paddle dryer, wetted materials of construction in Hastelloy C 22, aseptic design throughout, pressure proof (6 barg design pressure). With bayonet locking system for front door, segmented ball discharge valve, fiber optic vessel light installed on front door, separating wall for clean area and mechanical area, non contacting (lift-off) double mechanical seal. TI 0213 E - 07/07

Open the catalog to page 11All Comber Process Technology Srl catalogs and technical brochures

-

Pharmadry Technology

12 Pages

-

Pressofiltro Pharma Technology

30 Pages

-

Controls

6 Pages

-

Comber Historic

2 Pages

-

Heel Removal

6 Pages

-

Peripherals

11 Pages

-

Microwave

6 Pages

-

Containment

6 Pages

-

Termomix

10 Pages

-

Turbodry®

8 Pages

-

Condry®

8 Pages

-

Pilot Filter Dryer

12 Pages

-

Pressofiltro® Pharma

14 Pages

-

Pressofiltro® Chemical

6 Pages