Website:

Comber Process Technology Srl

Website:

Comber Process Technology Srl

Group: Heinkel Drying and Separation Group

Catalog excerpts

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Peripherals Heating / Cooling Condensation Vacuum TI 0055 - E - 06/05

Open the catalog to page 1

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Supplementary Equipment Supplementary equipment entailing condensation and vacuum systems, heating / cooling units, filtrate receivers, CIP cleaning systems and others, as to the specific requirements. The example indicated on the P&ID below shows a filter dryer, complete with condensation system, liquid ring vacuum pump, filtrate receiver and three independent pressurized heating cooling units. Two heating / cooling units are used for the...

Open the catalog to page 2

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Supplementary Equipment Heating / cooling unit with a capacity of 3 x 35 kW, for the individual heating and cooling of the vessel bottom and the agitator of the filter dryer, upper vessel and dust filter of the filter dryer as well as for the cooling of the solvent recovery system and ring liquid vessel and post condenser of the vacuum pump. Heating and cooling is with heat transfer fluid. Each circuit is equipped with its own pressurized...

Open the catalog to page 3

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Heating / Cooling Unit to process Cooling water and brine Out Steam In Condensate Out Cooling Water and brine In Process return Typical P&ID of a heating / cooling unit Heating / cooling unit for heating during the drying process and for cooling after completion of the drying as well as for the temperature control during filtration and other process stages. The unit is designed as a closed system, with circulation pump, heat exchangers,...

Open the catalog to page 4

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Heating / Cooling Unit Typical layout of a skid mounted heating / cooling unit Heating / cooling unit with circulating pump, plate heat exchanger for heating and cooling as well as all required instrumentation and controls. TI 0151 E - 06/05

Open the catalog to page 5

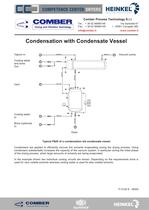

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Condensation with Condensate Vessel Vapors in Vacuum pump Cooling water and brine Out Vent Cooling water In Brine (optional) In Drain Typical P&ID of a condensation wit condensate vessel Condensers are applied to efficiently recover the solvents evaporating during the drying process. Using condensers substantially increases the capacity of the vacuum system, in particular during the initial phase of the drying process, when large amounts of...

Open the catalog to page 6

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Condensation with Condensate Vessel Vacuum pump Vapor feed Typical layout of a skid mounted condensation unit with condensate vessel Horizontally arranged condenser. By feeding the vapors to the condenser on one end and installing the condensate vessel at the opposite end of the condenser the vapors are forced along the cooling tube bundles resulting in a high condenser efficiency. The heat exchange surface of the condenser and the condensate...

Open the catalog to page 7

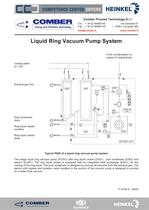

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Liquid Ring Vacuum Pump System From condensation or vapors In respectively cooling water In / Out Pumpe Exhaust gas Out Post condenser drain Ring liquid vessel overflow Ring liquid vessel drain Entleerung Typical P&ID of a liquid ring vacuum pump system Two stage liquid ring vacuum pump (PV301) with ring liquid vessel (D301), post condenser (E302) and ejector (EJ301). The ring liquid vessel is equipped with an integrated heat exchanger (E301)...

Open the catalog to page 8

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Liquid Ring Vacuum Pump System Typical layout of a skid mounted liquid ring vacuum pump system With two stage liquid ring vacuum pump, ring liquid vessel, post condenser and ejector. TI 0141 E - 06/05

Open the catalog to page 9

COMPETENCE CENTER DRYING AND SEPARATION GROUP SOLVENT FLUSH COOLING HATER Drying and Filtration Technology

Open the catalog to page 10

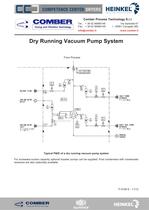

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Dry Running Vacuum Pump System Typical layout of a skid mounted dry running vacuum pump system with booster Vacuum pump (1) with dual three stage claw mechanism, booster pump (2) for increased suction capacity, flame arrestor (3), post condenser (4) and condensate receiver (5). TI 0161 E - 06/05

Open the catalog to page 11All Comber Process Technology Srl catalogs and technical brochures

-

Pharmadry Technology

12 Pages

-

Pressofiltro Pharma Technology

30 Pages

-

Controls

6 Pages

-

Comber Historic

2 Pages

-

Heel Removal

6 Pages

-

Microwave

6 Pages

-

Containment

6 Pages

-

Termomix

10 Pages

-

Turbodry®

8 Pages

-

Condry®

8 Pages

-

Pharmadry®

12 Pages

-

Pilot Filter Dryer

12 Pages

-

Pressofiltro® Pharma

14 Pages

-

Pressofiltro® Chemical

6 Pages