Website:

Comber Process Technology Srl

Website:

Comber Process Technology Srl

Group: Heinkel Drying and Separation Group

Catalog excerpts

COMPETENCE CENTER HEINKEL ^ ^^^^ ^^^^^^^^^^H DRYING AND SEPARATION GROUP Drying and Filtration Technology

Open the catalog to page 1

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pressofiltro® Heel Break-up System On larger filters the system is divided into several sections for maximum system efficiency Bursts of nitrogen are introduced from underneath the filter cloth, breaking the heel for easy removal Nitrogen manifold for heel break-up installed on the filter bottom of a 2.0 m² filter TI 0080 E - 02/04

Open the catalog to page 2

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pressofiltro® Heel Break-up System This system is designed to break-up the heel remaining on the filter cloth after discharging the filter for maximum product yield/recovery. Bursts of Nitrogen are introduced in the space below the filter bottom and the perforated filter support plates with the filter cloth. This breaks up and loosens the heel on the filter surface for a more complete and efficient product discharge by the agitator. These bursts...

Open the catalog to page 3

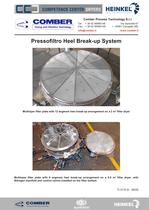

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 info@comber.it Via Garibaldi 67 I - 20061 Carugate (MI) www.comber.it Pressofiltro Heel Break-up System Multilayer filter plate with 12 segment heel break-up arrangement on a 2 m² filter dryer Multilayer filter plate with 8 segment heel break-up arrangement on a 0.5 m² filter dryer, with Nitrogen manifold and control valves installed on the filter bottom. TI 0170 E - 06/05

Open the catalog to page 4

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Whirl Snake - Total Heel Removal This system is designed to discharge heel remaining on the filter cloth after discharging the filter for maximum product yield/recovery. Using Nitrogen any remaining product on the filter plate is blown towards the discharge port. With the shaft rotating in addition to the rotating nozzle head all vessel areas are covered assuring full removal of remaining product. . Pneumatic motor . Reducing gear . Tri-Clamp...

Open the catalog to page 5

Comber Process Technology S.r.l. Tel.: + 39 02 99990146 Fax: + 39 02 99990148 Via Garibaldi 67 I - 20061 Carugate (MI) info@comber.it www.comber.it Pressofiltro® Heel Removal Various systems are available for the heel removal. A basic system with a hinged plug installed diagonally across the discharge valve permits pushing the heel remaining on the filterplate towards the discharge valve using a suitable scraper tool. Where personnel or product are to be protected this task can be performed protected by an isolator. Filterdryer with an additional plug for the heel removal (left) and...

Open the catalog to page 6All Comber Process Technology Srl catalogs and technical brochures

-

Pharmadry Technology

12 Pages

-

Pressofiltro Pharma Technology

30 Pages

-

Controls

6 Pages

-

Comber Historic

2 Pages

-

Peripherals

11 Pages

-

Microwave

6 Pages

-

Containment

6 Pages

-

Termomix

10 Pages

-

Turbodry®

8 Pages

-

Condry®

8 Pages

-

Pharmadry®

12 Pages

-

Pilot Filter Dryer

12 Pages

-

Pressofiltro® Pharma

14 Pages

-

Pressofiltro® Chemical

6 Pages