Catalog excerpts

INTERMICO manipulators of the H..S series have a gray cast iron housing. The cams operate in an oil bath. An output shaft through hole for passing services, is an option, the hole rotates. A protective device is provided to keep out water and dirt. > - compact design - high cycle speeds - short switching times - largely maintenance-free - positive locking - central through hole (on request) - low noise - various drive options - long life - no additional indexing required > These manipulators can be used wherever parts need to be moved with short switching times and smooth series of motions...

Open the catalog to page 5

In many applications, you will find that, by using two or more arms with grippers, it is possible to load and unload simultaneously at high speed. By adding more dwell positions, it is also possible to perform other functions together with the loading and unloading operations. Fig. 2 INTERMICO manipulator as a workpiece feeder Fig. 3 INTERMICO manipulator as a transfer device Fig. 4 INTERMICO manipulator in an insertion system. It has an additional drive for the transfer movement of a conveyor belt. > 3 size="-1">

Open the catalog to page 6

In order to select the right type of INTERMICO H..S manipulator, it is not sufficient to simply calculate the mass moment of inertia and lifting load and then determine the size of the INTERMICO manipulator accordingly. In the case of cam-controlled manipulators, the ratio of the total inertial radius to the geometrical radius of the installed globoid gear is also a decisive factor. We recommend that you get our Technical Office to calculate the right type of INTERMICO manipulator for you. For this purpose, please use the questionnaire at the end of the catalog, enclosing any relevant...

Open the catalog to page 7

Elastic elements must be avoided at all costs in the drive train. Use only torsionally rigid elements. Use only hardened parallel pins to connect attachment devices, e.g. grippers. Screw fittings should be secured with a screw retention fluid. Regular stopping of the INTERMICO manipulator when in motion period should be avoided to prevent damage to the device. If an inching control facility is provided for setting operations or if frequent emergency stops are likely during the movement phase, this must be taken into account in the design. > All INTERMICO manipulators are supplied without...

Open the catalog to page 8

H60G INTERMICO manipulators are available in the following models: GS Manipulator driven directly via cam shaft GU Manipulator with reducing gear on cam shaft GU1 Manipulator with built-in worm gear and GU2 free drive shaft GUF Manipulator with reducing gear and flange for mounting electric motors GUF1 Manipulator with built-in worm gear and GUF2 flange for mounting electric motors GM Manipulator with gear motor GM1 Manipulator with built-in worm gear and GM2 motor GB Manipulator with transmission brake motor GB1 Manipulator with built-in worm gear and GB2 brake motor > GS GUGU 1GU 2 GUFGUF...

Open the catalog to page 9

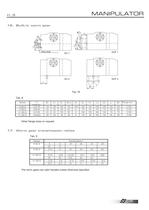

Movement sequence A1 Movement sequence A2 360 360 0 00 0 360 360 Fig. 9 Diagram of movements Diagram of movements > A1 A2 2 - stations 3 - stations 4 - stations 2 - stations 3 - stations 4 - stations Fig. 10 Other stations on request > : In the case of A1 movement sequences (rotation in extended position), the devices are supplied with an additional slewing bearing. (See page 19 for an additional slewing bearing) > 8 size="-2">

Open the catalog to page 11

Movement sequence A1 Movement sequence A2 > 0 0360 360 0 0 360 Fig. 11 Diagram of movements Diagram of movements > In the case of A1 movement sequences (pivoting in extended position), the devices are supplied with an additional slewing bearing. (See page 19 for an additional slewing bearing) > 9 size="-1">

Open the catalog to page 12

Number Max. out p ut Pivotin g Max. out p ut Series of torque of rotation axis Series angle torque of rotation axis stations Nm ()Nm H 65 S 2 220 H 65 S90180 > Max stroke 3 220 > Max stroke 60 mm 4 220 60 mm H 80 S 2 390 H 80 S90250 > Max stroke 3 590 > Max stroke 90 mm 4 360 90 mm H 105 S 2 820 H 105 S90510 > Max stroke 3 1390 > Max stroke 120 mm 4 780 120 mm H130 S 2 1470 H 130 S901100 > Max stroke 3 2250 > Max stroke 160 mm 4 1200 160 mm >

Open the catalog to page 14

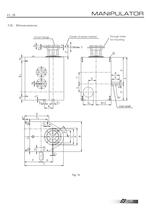

Driven flange Center of stroke markedThrough holesfor mounting >

Open the catalog to page 15

Load Load Load Load Load Load Load Load retracted extended retracted extended retracted extended retracted extended Fa ( N ) 600 750 11001400 Fr (N) 3200 10004000 900820012009200700 Mn (Nm) 100 80160 100340160380120 Mt (Nm) 180 250 5101100 >

Open the catalog to page 17

Drive shaft

Open the catalog to page 18

Series Bottom p lane after installation A B, C, D, E, F H 65 S > 6.5 7.5 H 80 S > 19.5 21 H 105 S > 32 34 H 130 S > 45 48

Open the catalog to page 21All COLOMBO FILIPPETTI catalogs and technical brochures

-

SRP

28 Pages

-

RIGIDIAL EN

40 Pages

-

Product Catalogue

19 Pages

-

RIGS04 - RIGSD6 - RIGSO0

16 Pages

-

SERVO ROLLER POSITIONER

12 Pages

-

CF3

16 Pages

-

H..S

28 Pages

-

RIGP

24 Pages

-

IR1601 - IR1801 - IR2001

20 Pages

-

IR1001 - IR1301

20 Pages

-

RIG04 - RIG06 - RIG09

32 Pages

-

INTERMITTENT MECHANISM

20 Pages

-

Parallel oscillating drives

16 Pages

-

Output overload clutches

6 Pages

Archived catalogs

-

FRET SAW MACHINES "HOBBY 50"

2 Pages