Website:

Codipro

Website:

Codipro

Group: Alipa

Catalog excerpts

GRADUP CERTIFICATIONS SAFETY FACTORS FIXED EYE BOLTS OR SWIVEL LIFTING RINGS? CODIPRO AT YOUR DISPOSAL THE EXPERT CHARTER TRAINING CENTER NOT ONLY SWIVEL LIFTING RINGS APPROVAL CODITRACER • GRADUP • ZERTIFIZIERUNGEN • DIE SICHERHEITSFAKTOREN • FESTE RINGSCHRAUBEN ODER ANSCHLAGWIRBEL ? • CODIPRO STETS ZU IHREN DIENSTEN • DIE EXPERTENCHARTA • SCHULUNGEN • NICHT NUR ANSCHLAGWIRBEL • DIE TYPENPRÜFUNG • CODITRACER GRADUP CERTIFICATIONS LES COEFFICIENTS DE SÉCURITÉ ANNEAU FIXE OU ARTICULÉ ? CODIPRO À VOTRE SERVICE LA CHARTE DE L’EXPERT CENTRE DE FORMATION PAS UNIQUEMENT DES ANNEAUX DE LEVAGE HOMOLOGATION CODITRACER GRADUP CERTIFICACIÓN LOS COEFICIENTES DE SEGURIDAD ¿CÁNCAMO FIJO O ARTICULADO? CODIPRO A SU DISPOSICIÓN LA CARTA DEL EXPERT

Open the catalog to page 1

GRADUP The CODIPRO team, always listening to the market and keeping an eye on its trends, works constantly to improve and develop its range of swivel lifting rings. The GRADUP range has been especially developed to be the quintessential swivel lifting ring, particularly in terms of the quality of the raw materials used. The CODIPRO research department, supported by advice from internationally renowned research centers, selected the best quality steel to achieve the best balance between tensile strength, breaking load and fatigue strength. Each component of the GRADUP lifting rings’ hinge...

Open the catalog to page 2

GRADUP When should GRADUP be used? Anytime and anywhere in a traditional industrial environment: the GRADUP swivel lifting rings are designed to be used within a temperature range of -20°C to +200°C (-4°F to +392°F). Use recommendations provided in 15 languages give a detailed description of the conditions for use. For extreme applications such as offshore use, or very low/very high temperatures, etc. our engineers at the CODIPRO research department are available to provide details about the composition of our lifting rings: strength, chemical composition, mechanical strength, tensile...

Open the catalog to page 3

CERTIFICATIONS OF CODIPRO’S LIFTING RINGS CODIPRO pays particular attention to the quality of its swivel lifting rings throughout the manufacturing process. These safety rings comply with the new European Regulation 2023/1230 and the Machinery Directive 2006/42/EC. All stages of the production process are strictly controlled by an ISO 9001 and ISO 14001-certified quality management system. Long before they are assembled, the components that will become a lifting ring are subject to very strict specifications. For each forged part, 100% of the surfaces are subjected to magnetic particle or...

Open the catalog to page 4

CERTIFICATIONS OF CODIPRO’S LIFTING RINGS CODIPRO’s lifting rings are also tested after each production run and before they are put on the market. As CODIPRO’s production process is ISO 9001 certified, and as recommended by standard 1677-1, tests are carried out according to the following criteria: TYPE Each shall sustain the manufacturing proof force without permanent deformation Magnetic particle or dye penetrant examination on forged surfaces of components acc to EN 10228-1 or EN 10228-2 Indications greater than 2 mm in length shall not be permitted Based on all these indications,...

Open the catalog to page 5

SAFETY FACTORS How is the safety factor calculated? In order to guarantee your safety, each CODIPRO swivel lifting ring has to undergo a series of very strict tests: > Breaking tests; > Proof load tests at 2.5 x WLL; > Fatigue tests. Calculation of the safety factor is based on the results of breaking tests. It is the ratio of the WLL (Working Load Limit) to the breaking test. For example, a ring with a WLL of 1 t with a 5:1 safety factor will have to obtain a breaking load of at least 5 t. CODIPRO favours the 5:1 factor True to its values, CODIPRO has always favoured the 5:1 factor because...

Open the catalog to page 6

FIXED EYE BOLTS OR SWIVEL LITFING RINGS? Traditional fixed eye bolts (also known as DIN 580 rings) are intended for straight lifting: at a 0° angle to the direction of pulling. They are strictly prohibited for perpendicular lifting: at a 90° angle to the pulling direction. Swivel lifting rings are specially designed for turning loads. CODIPRO rings can be used in any kind of hoisting situation whether there is an angle or for a straight lift, and/or for all types of lifting. The design of CODIPRO swivel rings allows pulling from any angle and rotating safely under load. Painted in orange...

Open the catalog to page 7

CODIPRO AT YOUR DISPOSAL For more than 45 years, CODIPRO has been providing lifting equipment distribution professionals with expertise, technology and all the skills of a manufacturer that has become a major player in the international market. From single items to large ranges, from standard to specific, CODIPRO manufactures and sells a complete range of swivel lifting rings for many sectors such as the molding industry, material handling, transport, logistics, the shipbuilding industry, offshore, lifting, aeronautics and wind power. Technical expertise The safety of people and goods is...

Open the catalog to page 8

CODIPRO AT YOUR DISPOSAL To ensure your safety, several types of tests must be carried out to check the strength and quality of the swivel lifting rings: > Breaking test; > Proof test load at WLL x 2.5; > Fatigue testing: pull/release tests on a series of 20,000 cycles at WLL x 1.5. To provide even more safety, CODIPRO is equipped with a test bench allowing testing up to 80 tons to be carried out internally. The tests are then validated by an external certification body. Customer service At CODIPRO, cooperation between customer, distributor and producer is a central priority. Through its...

Open the catalog to page 9

THE EXPERT CHARTER CODIPRO supplies its swivel lifting rings via a network of distributors. The quality of the information provided depends on the skills of these distributors. That is why CODIPRO has decided to support its loyal distributors and help them develop their skills. This innovative approach by CODIPRO reflects its values of honesty, professionalism and transparency. Henceforth classified as EXPERTS, CODIPRO’s distributors have the benefit of coaching, the content of which is described in the «EXPERT Charter». The privileges reserved for EXPERT distributors enable them to stand...

Open the catalog to page 10All Codipro catalogs and technical brochures

-

Central Lifting Systems

4 Pages

-

QL.DSR

2 Pages

-

SS.QL.DSR

2 Pages

-

DSR

2 Pages

-

Giga DSS

1 Pages

-

DSS

2 Pages

-

FE.DSS

2 Pages

-

FE.DSR

2 Pages

-

SS.FE.DSS

2 Pages

-

SS.DSR

2 Pages

-

SS.FE.DSR

2 Pages

-

FE.SEB

2 Pages

-

SS.SEB

2 Pages

-

SS.DSS

2 Pages

-

OS.DSS

1 Pages

-

OS.DSR

1 Pages

-

WE.DSR-WE.DSS

1 Pages

-

TSR

2 Pages

-

DSH

2 Pages

-

DSP

2 Pages

-

ARC

1 Pages

-

SLM 40

1 Pages

-

SLM

1 Pages

-

CSS

1 Pages

-

PE.SEB - SS.PE.SEB

1 Pages

-

ADA

1 Pages

-

MEGA.DSS+

2 Pages

-

SEB

2 Pages

-

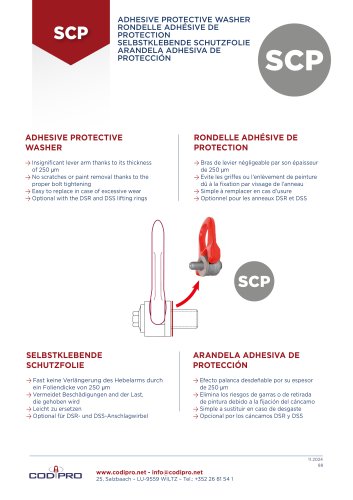

Adhesive Protect Washer SCP

1 Pages

-

Lashing

1 Pages

-

RFID

1 Pages

-

Centring

2 Pages

-

Blocking Spring

1 Pages

Archived catalogs

-

Presentation of CODIPRO

14 Pages

-

CODIPRO - Catalogue 2015

59 Pages

-

Presentation of the Giga DSS

4 Pages

-

SEB+C

1 Pages

-

DSH+C

1 Pages

-

DSP+C

1 Pages

-

DSR+C

1 Pages

-

DSS+C

1 Pages

-

TSR+C

1 Pages

-

Swivel Eye Bolt: SEB

1 Pages

-

PE.SEB

1 Pages