Catalog excerpts

LACLUSIENNE C L U F I X www.laclusienne.com LOCKFIX™ boulons de structure lockbolts

Open the catalog to page 1

2009.A 2009.A Think LOCKFIX™ as an alternative to Nut & bolt assembly: - assembly is cumbersome because it necessitates holding both the nut and the bolt during assembly - risk of loosening, especially when the assembly is subject to vibration - no possibility of locking the assembly Arc welding: - an infl exible welding process - high level of material heating - workpiece deformation - scarcity of qualifi ed arc-welders - an unattractive solution (weld spots) Penser LOCKFIX™ en alternative à Ensemble vis-écrou : - montage contraignant nécessitant la tenue de la vis mais également de...

Open the catalog to page 3

2009.A 2009.A 7 Pourquoi utiliserLOCKFIX™ W h y u s e Advantage Proof Benefi t Very high levels of mechanical performance Large pin diameter enabling very high tensile and shearing resistances Mechanical assembly Refer to data sheet Guarantee of perfect assembly Simple installation process No complex tools are required, just a simple riveting tool No welding 1) The solution immediately covers its own costs 2) No special skills required Flexibility in installation Can be installed on large assemblies No special skills required Organisational fl exibility Very high-speed installation rate...

Open the catalog to page 4

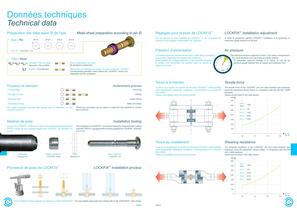

2009.A 2009.A 9 Axe Pins Bague Collar Standard type S Morphologie standard Standard S type Standard design Épaulée type E L'épaulement permet un appui sur une surface plus importante, favorisant la répartition des efforts Flanged E type The fl ange improves the distribution of force over a larger surface area Compacte type C Limite l'encombrement après assemblage Compact C type Limits protusion after assembly Tête Standard Morphologie standard Standard Head Standard design Tête Large Le diamètre de tête accru améliore la répartition des contraintes mécaniques en les diffusant sur une...

Open the catalog to page 5

2009.A 2009.A 11 Réglages pour la pose de LOCKFIX™ LOCKFIX™ installation adjustment Afi n de garantir la pose optimale de LOCKFIX™, il est nécessaire de s’assurer de la pression d’alimentation de l’appareil : In order to guarantee optimal LOCKFIX™ installation, it is necessary to check the supply pressure to the tool: La pression minimum requise est de 6 bars. Cette valeur correspond à la pression habituelle d’un réseau d’air comprimé. Pour garantir un rivetage optimum, il est conseillé d’équiper le réseau d’un manomètre de contrôle placé en amont de l’appareil de pose. The minimum pressure...

Open the catalog to page 6

2009.A 2009.A 13 Gamme : Range: 12 = LOCKFIX™ Matière : Material: A = Acier / Steel Diamètre de l'axe ou diamètre intérieur de la bague : Pin diameter or collar internal diameter: De From 048 <=> Ø4.8 mm À To 096 <=> Ø9.6 mm Épaisseur de sertissage maximum si axe : Maximum crimping thickness if pin: Exemple / Example : 095 <=> 9.5 mm 000 si bague / if collar 12 A 064 ASX 095 Z Traitement de surface : Finish: Z = Zinc Cr3 X = Pas de traitement No fi nish Morphologie : Shape: Composant / Component A = Axe / Pin B = Bague / Collar X = Pas de spécifi cation Empty fi eld Tête / Head S = Standard...

Open the catalog to page 7

22 LA CLUSIENNE-CLUFIX : Solutions et composants d’assemblage - Fastening solutions 2009.A 23 313, rue Louis ARMAND - BP 220 - Z.I. des grands prés - 74304 Cluses Cedex France - Tel. +33 (0)4 50 98 13 13 - Fax. +33 (0)4 50 98 28 89 - www.laclusienne.com 2009.A LA CLUSIENNE-CLUFIX : Solutions et composants d’assemblage - Fastening solutions 313, rue Louis ARMAND - BP 220 - Z.I. des grands prés - 74304 Cluses Cedex France - Tel. +33 (0)4 50 98 13 13 - Fax. +33 (0)4 50 98 28 89 - www.laclusienne.com LA CLUSIENNE WARRANTS THAT THE PRODUCTS SOLD WILL BE FREE FROM DEFECTS IN MATERIAL AND...

Open the catalog to page 12All Clufix catalogs and technical brochures

-

BOLTOFIX

1 Pages

-

RIVETFIX

1 Pages

-

Crimping hand pliers

1 Pages

-

Oleopneumatic crimping tools

4 Pages

-

CLUFIX-STUD

2 Pages

-

CLUFIX ®

5 Pages

-

Oleopneumatic press

1 Pages

-

Riveting hand pliers

1 Pages

-

Oleopneumatic riveting tools

3 Pages

-

NUTFIX?

3 Pages

-

FLUSHFIX®

3 Pages

-

ENDFIX®

3 Pages

-

CLUFIX®

5 Pages

-

CAPTIFIX™ HR Stainless Steel

11 Pages

-

CAPTIFIX™ 316L Stainless Steel

14 Pages

-

CAPTIFIX™ Stainless Steel

14 Pages

-

CAPTIFIX™ Steel

14 Pages

-

STUDFIX™ Steel - Aluminium

16 Pages

-

SPACERFIX™ Aluminium

15 Pages

-

SPACERFIX™ HR Stainless Steel

15 Pages

-

SPACERFIX™ 316L Stainless Steel

16 Pages

-

SPACERFIX™ Stainless Steel

16 Pages

-

SPACERFIX™ Steel

16 Pages

-

NUTFIX™ Steel - Aluminium

16 Pages

-

FLUSHFIX®

9 Pages

-

ENDFIX®

18 Pages

-

CLUFIX-STUD™

9 Pages

-

SOFTERFIX™

16 Pages

-

CLUFIX® Aluminium

14 Pages

-

CLUFIX® 316L Stainless Steel

18 Pages

-

CLUFIX® Stainless Steel

18 Pages

-

CLUFIX® Steel

17 Pages