Catalog excerpts

CE only applies to the entire machine when P/N 40831 is included WELDING MACHINE OPERATING MANUAL ORIGINAL INSTRUCTIONS

Open the catalog to page 1

LACK OF FUSION TO THE BORE

Open the catalog to page 4

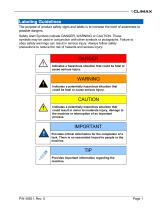

Labeling Guidelines The purpose of product safety signs and labels is to increase the level of awareness to possible dangers. Safety Alert Symbols indicate DANGER, WARNING or CAUTION. These symbols may be used in conjunction with other symbols or pictographs. Failure to obey safety warnings can result in serious injury. Always follow safety precautions to reduce the risk of hazards and serious injury. DANGER Indicates a hazardous situation that could be fatal or cause serious injury. WARNING Indicates a potentially hazardous situation that could be fatal or cause serious injury. CAUTION...

Open the catalog to page 5

Safety Precautions and Rules for Safe Operation • • • • • • The BW1000 is designed for safety and ease of use. As with the operation of any machinery, safety depends on the operator. It is most important that the operators read and understand the specific instructions for set-up and operation of the BW1000 found in the operator's guide as well as the following safety information. Only qualified individuals should attempt set-up, maintenance, and operation of the BW1000. To assure that nothing gets caught in rotating BW1000 members, avoid wearing loose fitting clothing and keep hair back or...

Open the catalog to page 6

Safety Precautions: General Hazards The primary challenge for most on-site maintenance is that repairs are often done under difficult conditions. Climax Portable Machining & Welding Systems leads the way in promoting the safe use of portable machine tools. Safety is a joint effort. As the operator of this machine, you are expected to do your part by scrutinizing the job site and closely following the operating procedures outlined in this manual, your own company rules, and local regulations. Save all warnings and instructions for future reference. WARNING Read all safety warnings and all...

Open the catalog to page 7

HOSES, PENDANT AND ELECTRICAL CABLES Do not abuse cables. Never use the cord for carrying, pulling or unplugging. Remove any and all kinks before straightening the cable. Keep cords and hoses away from heat, oil, sharp edges or moving parts. Plugs must match the outlet. Never modify the plugs in any way. Do not use an adapter plug with grounded power tools. Do not expose the machine to rain or wet conditions. Always examine hoses and cables for damage before use. Be cautious and never drop electrical equipment, this will damage the components. REPETITIVE MOTION Individuals can be...

Open the catalog to page 8

Risk assessment checklist Use these checklists as part of your on-site risk assessment and include any additional considerations that may pertain to your specific application. TABLE 1. RISK ASSESSMENT CHECKLIST BEFORE SET-UP Before Set-up I took note of all the warning labels on the machine. I removed or mitigated all identified risks (such as tripping, cutting, crushing, entanglement, shearing, or falling objects). I considered the need for personnel safety guarding and installed any necessary guards. I read the Machine Assembly instructions and took inventory of all the items required...

Open the catalog to page 9

Limited Warranty CLIMAX Portable Machine Tools, Inc. (hereafter referred to as “CLIMAX”) warrants that all new machines are free from defects in materials and workmanship. This warranty is available to the original purchaser for a period of one year after delivery. If the original purchaser finds any defect in materials or workmanship within the warranty period, the original purchaser should contact its factory representative and return the entire machine, shipping prepaid, to the factory. CLIMAX will, at its option, either repair or replace the defective machine at no charge and will...

Open the catalog to page 10

Bortech Limited Warranty Bortech warrants new equipment, not classified as expendable, against defects in workmanship and material for one year of normal use from the date of receipt by the end user. The following conditions shall be met in order for this warranty to be enforced: • Equipment has been stored in accordance with Bortech's instructions. • Equipment has been operated in accordance with Bortech's instructions. • Equipment has been maintained in accordance with Bortech's instructions. • Equipment has not been partially or completely disassembled, or otherwise tampered with -...

Open the catalog to page 11

CE Data DECLARATION OF CONFORMITY Issued by: Climax Portable Machining and Welding Systems (Original Dated) Type of Equipment: Automated Bore Welding Equipment Brand Name: Climax Portable Machining and Welding Systems BoreWelder Model Number: Serial Numbers: Audible Noise Levels: Surface sound pressure level (in dBA) 70 dBA Sound power level (in dBA) 84 dBA Sound pressure level for operator (80 dBA) and bystander (75 dBA) Please note that this information is provided as a guide and you, or your manufacturer, are cautioned that specific requirements are contained within each directive.

Open the catalog to page 12

Safety In accordance with CE standards • Crushing risk exists if clamps are not tightened. • Modification of safety features may result in operator or bystander harm. • Do not integrate with faulty or poorly maintained equipment. • Modification of thermal safety features may result in operator or bystander harm. • Modification of noise safety features may result in operator or bystander harm. • Modification of vibration safety features may result in operator or bystander harm. • Grease and/or oil native to machinery may result in allergic reaction to operator. • Smoke from welding metals...

Open the catalog to page 14

Operation The BW1000 is an automated welding device that uses a rotating and helically retracting spindle/torch, which must be coupled with a MIG Wire-feeder to deposit Weld on the surface of a bore or pin. The rate of axial feed per revolution is fixed. Torch selection, and/or adjustments to the swivel head accommodate differences in bore diameter. During set-up, the operator is required to: • Align the Borewelder to the bore, (using either the appropriate interface tooling for Boring bar to be used, or the Bortech Adjustable base). • Determine the proper torch/bore clearance, and to set...

Open the catalog to page 15All CLIMAX catalogs and technical brochures

-

PL2000 PORTABLE LATHE

6 Pages

-

Flange Facing

4 Pages

-

CM6200 CIRCULAR MILLING MACHINE

334 Pages

-

BB3000 LINE BORING MACHINE

8 Pages