Website:

CleanAir Europe

Website:

CleanAir Europe

Group: CleanAir Engineering

Catalog excerpts

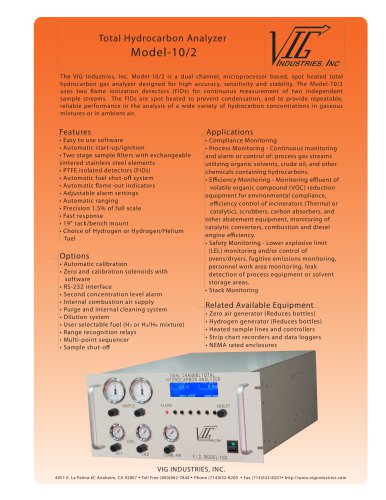

Dual Channel Heated Total Hydrocarbon Analyzer The VIG Industries, Inc. Model-20/2 is a dual channel, microprocessor based, oven heated total hydrocarbon gas analyzer designed for high accuracy, sensitivity and stability. The Model-20/2 uses two Flame ionization detectors (FIDs) For continuous measurement oF two independent sample streams. All components that come in contact with the sample through analysis are maintained in a temperature-controlled oven to prevent condensation, and to provide repeatable, reliable performance in the analysis oF a wide variety oF hydrocarbon concentrations in gaseous mixtures or in ambient air. •Automatic start-up / ignition •Heated sample pump heads •Two stage sample filters with exchangeable sintered stainless steel elements • PTFE isolated detectors (FIDs) •Automatic fuel shut off system •Automatic flame-out indicators •Adjustable alarm and oven settings •Automatic ranging • Precision 1 % of full scale • Fast response •Choice of Hydrogen or Hydrogen/Helium •Automatic calibration •Zero and calibration solenoids with •Second concentration level alarms • Internal combustion air supply •Purge and internal cleaning system • Dilution system • User selectable fuel (H2 or H2/He mixture) •Range recognition relays •Multi-point sequencer •Sample shut-off Process Monitoring- Continuous monitoring and alarm or control of: process gas streams utilizing organic solvents, crude oil, and other chemicals containing hydrocarbons. Efficiency Monitoring - Monitoring effluent of volatile organic compound (VOC) reduction equipment for environmental compliance, efficiency control of incinerators (Thermal or catalytic), scrubbers, carbon absorbers, and other abatement equipment, monitoring of catalytic converters, combustion and diesel engine efficiency. Safety Monitoring - Lower explosive limit (LEL) monitoring and/or control of ovens/dryers, fugitive emissions monitoring, personnel work area monitoring, leak detection of process equipment or solvent storage areas. Stack Monitoring Related Available Equipment •Zero air generator (Reduces bottles) •Hydrogen generator (Reduces bottles) •Heated sample lines and controllers •Strip chart recorders and data loggers •NEMA rated enclosures 051 E. La Palma #C Anaheim, CA 92807 • Toll Free (800)862-7844 • Phone (714)632-8200 • Fax (714)632-8201 • http://www.vigindustries.

Open the catalog to page 1

Standard Specifications Measuring Method - 2 Oven Heated, Flame Ionization Detectors (FIDs) Measurement Range/Standard Ranges - (4 Ranges per amplifier, 2 amplifiers per analyzer) •0-10, 0-100, 0-1000, 0-10000ppm (Lower detection limit 0.01 ppm) or •Other ranges available upon request Zero & Span Noise - Less than 0.2% of full scale Zero & Span Drift - +/- 1 % full scale per 24 hours Linearity- Within 1% of full scale through all ranges Repeatability - Within 1% of full scale through all ranges Stability - Within 1% of full scale through all ranges Oxygen Synergism - Within 1% of full scale...

Open the catalog to page 2All CleanAir Europe catalogs and technical brochures

-

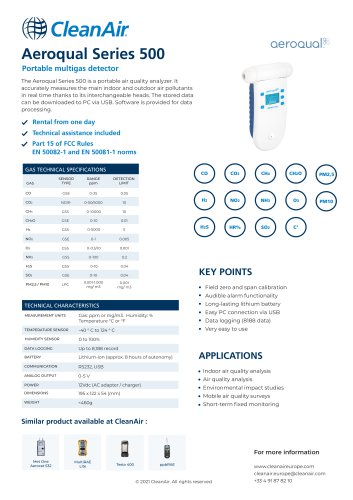

Aeroqual Series 500

1 Pages

-

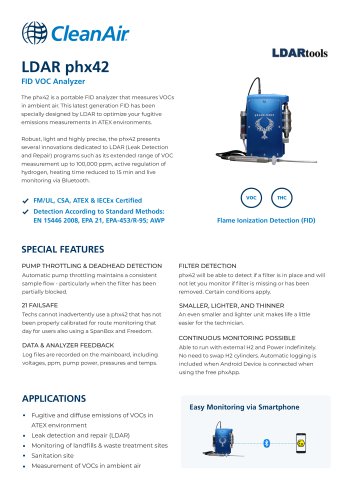

LDAR phx42

2 Pages

-

ETG MCA 100 SYN

2 Pages

-

MCA 100 Syn

1 Pages

-

ETG MCA 100 SYN P

2 Pages

-

ETG MCA 100 BIO P

2 Pages

-

ETG MCA 100 BIO

2 Pages

-

ETG 6500 SYN WM

2 Pages

-

ETG 6500 BIO WM

2 Pages

-

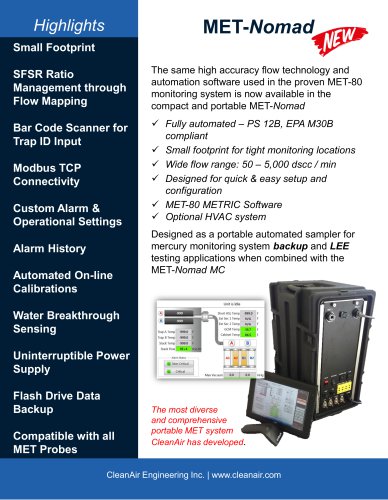

MET-80

2 Pages

-

ETG 6900 TDL NH3

1 Pages

-

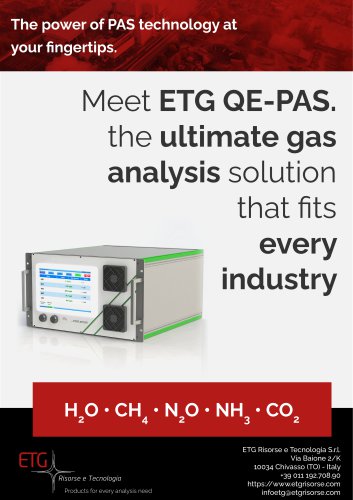

ETG QE-PAS

2 Pages

-

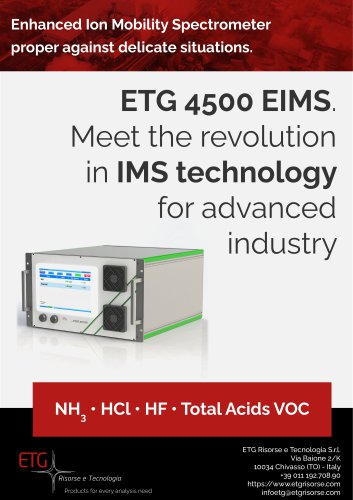

ETG 4500 EIMS

3 Pages

-

ETG 6900 TDL HCl

1 Pages

-

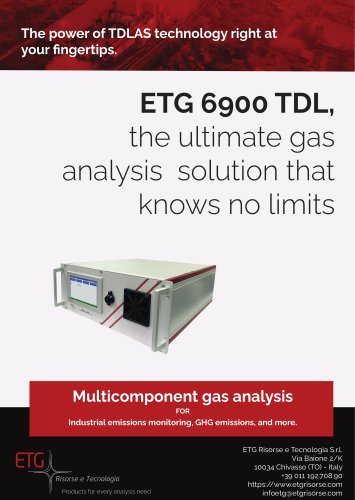

ETG 6900 TDL

4 Pages

-

Jerome J405

2 Pages

-

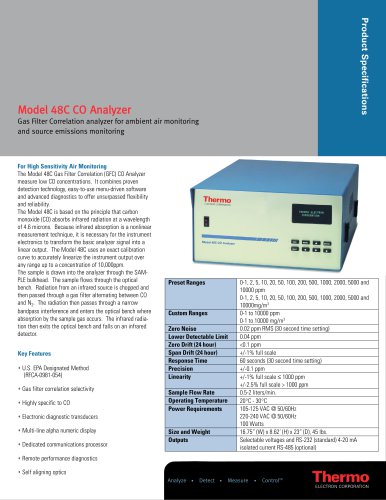

Model 48C CO Analyzer

2 Pages

-

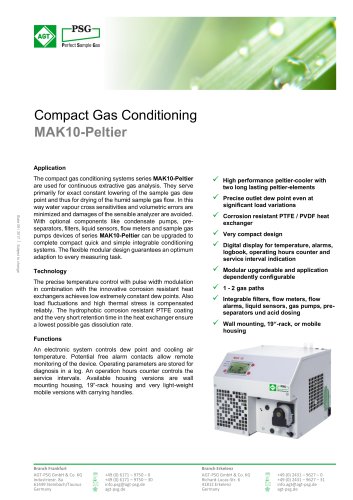

MAK10-Peltier

6 Pages

-

catalogue 2011

100 Pages

-

Model-20

2 Pages

-

Model-10/2

2 Pages

-

Model-10

2 Pages

-

Model-200

2 Pages