Website:

CLARK Material Handling

Website:

CLARK Material Handling

Group: CLARK Material Handling

Catalog excerpts

CLARK ELECTRIC STACKER TRUCKS WS10M • Max. 1950 mm lift height. • Optimum solution for light applications. • Light & Compact. • Easy operation. • Maintenance-free block batteries. • Integrated on-board charger. • Max. 4800 mm lift height. • Precise and controlled fork lowering. • Adjusted max travel speed with raised load. • CLARK SpeedControl (CSC). • Standard side battery removal. • Max. 3300 mm lift height. • Optimum solution for light applications. • For workloads up to 1t to a height of 3300 mm. • Maintenance-free block batteries. • Integrated on-board charger • Max. 5210 mm lift...

Open the catalog to page 2

Precise and Ergonomic Operation All functions for lifting and lowering are integrated in an ergonomic tiller head. This enables precise, accurate and safe material handling. In addition a 4-point-wheel-configuration on all CLARK stacker trucks ensures the best residual capacity and stability even with maximum lift heights. SX uprights have outstanding visibility. With an optimal wide rail configuration, CLARK provides the best possible fork visibility. With widths of 480 mm on the Standard upright and 390 mm on the Triplex, this allows for precise handling and increases safety during the...

Open the catalog to page 3

WS & SX STANDARD FEATURES & BENEFITS TILLER HANDLE Comfortable and Safe • uick and easy operation. Q • Automatic return to neutral position when the tiller arm is released. • Ergonomic tiller switches. • Control of all operation commands left- and right-handed. Automatic Parking Brake • Safe operation on gradients and ramps. • Automatic parking brake with drive switch activation. * SX12/16 CLARK SpeedControl (CSC) • Normal drive position (N) enables maximum speed • In SpeedControl position (S) the maximum speed is reduced *WSX12/14, WSXD20 CLARK SpeedControl (CSC) Safe and Controlled...

Open the catalog to page 4

HANDLE OPERATION IN VERTICAL POSITION PIN CODE ACTIVATION • ruck activation using a T 4-digit PIN code. • ptional underside tiller O handle button. • Protection against unauthorized usage. • For precise and sensitive operation in tight spaces. • Possible automatic shutdown. * SX12/16 Press 1x = slow forward movement Press 2x = slow backward movement SX12 & SX16 INITIAL LIFT For Uneven Floors and Gradients • Increased ground clearance under the support arms and battery compartment. • More ground clearance even with nominal load. • Best solution for ramp and gradient applications. Double-Deck...

Open the catalog to page 5

WS(X) STANDARD FEATURES & BENEFITS WSX12 & WSX14 Made for Industrial Applications • For storage and handling in racks up to 4800 mm. • Low-maintenance AC traction motor. • Compact dimensions. • Steel fabricated battery box cover. • Battery compartment for 195Ah or 225Ah batteries. • CLARK SpeedControl (CSC) and automatic speed adjustment with a raised load. • Two different lowering speeds for enhanced productivity. WS10 & WS10M Light Operation • Optimum solution for light applications with loads up to 1,0t. • Efficient 2,2kW hydraulic motor. • Designed for short traveling distances. •...

Open the catalog to page 6

SX12/SX16 STANDARD FEATURES & BENEFITS Mast cushioning during lifting and lowering Motor-driven proportional hydraulic system Protected lift cylinders Outstanding visibility Best residual capacities even at maximum lift height USER FRIENDLY AND ROBUST For the Most Demanding Applications • Robust and durable. • Best residual capacities thanks to a 4-point-wheelconfiguration. • Up to 375Ah battery capacity. Easy Handling • he tiller arm is fitted in a central position which allows T symmetrical operation. • Lifting and lowering fully proportional and precise. • Crawl speed switch on tiller...

Open the catalog to page 7

Note: “Photos and illustrations are based on information at time of printing and are subject to change without notice. Some products may be shown with optional equipment. Model assumption detail variations are possible.” CLARK EUROPE GmbH Dr.-Alfred-Herrhausen-Allee 33 · 47228 Duisburg / Germany Tel: +49 (0)2065 499 13-0 · Fax: +49 (0)2065 499 13-290 Info-europe@clarkmheu.com · www.clarkmheu.com © 2015 CLARK EUROPE GmbH

Open the catalog to page 8All CLARK Material Handling catalogs and technical brochures

-

CLARK Low Lift Pallet Truck

12 Pages

-

CLARK Full Line

8 Pages

-

CLARK Pallet Stacker

8 Pages

-

Brochure CLARK CRX10 25FL EN

8 Pages

-

Specification sheet SRX14/16

6 Pages

-

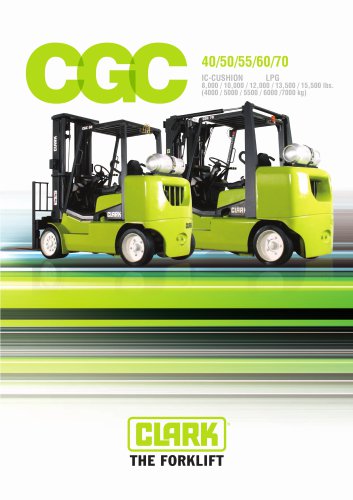

Specification sheet CGC40-70

6 Pages

-

Specification sheet S20-32C

6 Pages

-

Specification sheet C15-20sC

6 Pages

-

Specification sheet GTS20-33

6 Pages

-

Reach truck SRX14/16

8 Pages

-

Electric stacker SX12/16

8 Pages

-

CLARK Full Line

8 Pages

-

SX 12/16

6 Pages

Archived catalogs

-

Specification sheet WPio12

6 Pages

-

WSXD20

8 Pages

-

Brochure CLARK S-Series

8 Pages

-

WPX18

8 Pages

-

WP15

8 Pages

-

WPio12

2 Pages

-

C 15/18/20s(C) GEN2 Series

8 Pages

-

EPX 16/18/20s

5 Pages

-

TMX 13/15s/15/18/20x

7 Pages

-

GEX 40/45/50

8 Pages

-

GEX/GTX 16/18/20s

8 Pages

-

C40-55s

8 Pages

-

GTS20-33

8 Pages

-

WS 10M

8 Pages

-

WS 10

8 Pages

-

WSX 12/14

8 Pages

-

WSXD 20

8 Pages

-

CRT 16/20SE ac

8 Pages

-

CRT 14/16/20 ac

8 Pages

-

SRX 14/16

8 Pages

-

CRT 13/16K ac

8 Pages

-

WP & PX

8 Pages

-

PX20

8 Pages

-

C 60/70/75/80 GEN2 Series

8 Pages

-

C 40/45/50/55s Gen2 Series

8 Pages

-

C 25-35/20C-32C Gen2 Series

8 Pages

-

CRX Series

6 Pages

-

CQ 20/25/30

6 Pages

-

CLARK Evolution

2 Pages

-

CTX 40/70

8 Pages

-

GEX 20/25/30(s/L)

8 Pages

-

Electric Reach Truck

8 Pages

-

Electric Power Stacker

8 Pages

-

Electric Pallet Truck

8 Pages

-

CGC 40/70 NON EU

10 Pages

-

C 15C/18C/20Cs GEN2 Series

8 Pages

-

GenEX Series GEX 40/45/50

8 Pages

-

CLARK_FULL-LINE

8 Pages

-

Data sheet CLARK-C40-55s

6 Pages

-

CLARK C60-80

8 Pages

-

Clark C 20-35

16 Pages

-

Clark CMP 50-75

2 Pages

-

Clark CMP 40-50s

2 Pages

-

CLARK CMP15-20

2 Pages

-

CLARK-GTX/GEX16-20s

12 Pages

-

CLARK CQ 20-30

6 Pages

-

Brochure CRX

6 Pages

-

Data sheet CLARK-CMP40-50s

6 Pages

-

Data sheet Clark-CMP50-75s

6 Pages

-

New GEX 20-30

10 Pages

-

Data sheet CLARK-GEN2 C20-35

7 Pages