Website:

CLARK Material Handling

Website:

CLARK Material Handling

Group: CLARK Material Handling

Catalog excerpts

• The operator compartment is supported on specially engineered isolating mounts, reducing the amount of engine noise and vibration transmitted to the operator ensuring a more comfortable ride. Highly Maneuverable, Easily Serviceable, Broadly Flexible, Extremely Dependable The GEN2-series proudly adds to CLARK’s unique history of building the best forklifts with evolutionary steps in ergonomics, power, safety, durability, and performance. These models, designed for distribution, manufacturing and warehousing of all types, are suited for the toughest applications.

Open the catalog to page 2

The large operator compartment’s controls and seating are designed to maximize operator space and comfortably accommodate the ninety-five percentile in height range of the world’s adult population. • Nested upright rails provide positive rail interlock and a narrow “column” to maximize the vision window. The overhead guard safety bars run parallel to the operator’s line of sight resulting in a clear, unobstructed view. Smooth Control + Easy Operation = Operator Confidence & Optimum Comfort

Open the catalog to page 3

• With four turns lock-to-lock the hydrostatic power steering provides the operator with excellent maneuverability and ease of control. • Low, open foot steps with traction plates make entry/exit quick, easy and safe... from either side. Rugged Durability, High Performance, Extreme Environments, Demanding Applications The GEN2-series is designed to tackle any task placed in its path. The separate radiator ensures optimum cooling for the transmission and provides maximum cooling for the engine, transmission and for the axle in the harshest environments and the most demanding applications....

Open the catalog to page 4

All CLARK forklifts, associated devices and tools are in conformance to CE, ANSI ASME,OSHA and UL standards. • Neutral Start: If the Gear lever is not positioned in neutral, the engine will not start. • Tilt Lock Valve: Prevents the accidental forward tilting of the mast while engine is switched off. • Gas Springs with Automatic Lock: Prevents accidental closure of hood. • Safety valve: Prevents accidental uncontrolled mast lowering in the event of oil pressure hose damage. • orward and reverse travel is not possible whilst the parking brake is in the on F Safety position. Maximum...

Open the catalog to page 5

GEN2 STANDARD FEATURES & BENEFITS HydrauliC System l Simple & Error Proof • Foot-applied brake can be released by hand or foot. • Transmission disengages when parking brake is set preventing driving against brakes. • Horn will sound if brake is not set after 3 seconds from when the engine is shut off. Maximum Horsepower • Uses a load-sensing flow control valve for steering to reduce horsepower loss and heat buildup. l Optimum Performance Of Attachments • The main hydraulic valve incorporates adjustable flow controls for tilt and auxiliary functions. l Sectional Design • Allows for easy...

Open the catalog to page 6

Rugged Design • Linkage pivot pins have a “double shear” design to withstand impact without loosening or breaking. l Simple Axle Design • ouble-ended cylinder provides steering force. D dash display l Microprocessor RUGGED UPRIGHT AND CARRIAGE l I-Channel Construction • Maximizes visibility and stiffness, allows for internal hosing and wiring. • Six carriage rollers and two side-thrust rollers minimize deflection and sideplay, reduce roller contact stress and extend component life. • Hydraulic cushioning valves provide silent staging of the rails to reduce shock during both lifting and...

Open the catalog to page 7

CLARK EUROPE GmbH Neckarstraße 37 · D-45478 Mülheim an der Ruhr Tel: +49 (0)208-37 73 36-0 · Fax: +49 (0)208-37 73 36-36 Info-europe@clarkmheu.com · www.clarkmheu.com © 2011 CLARK Material Handling Company Printed in Germany

Open the catalog to page 8All CLARK Material Handling catalogs and technical brochures

-

CLARK Low Lift Pallet Truck

12 Pages

-

CLARK Full Line

8 Pages

-

CLARK Pallet Stacker

8 Pages

-

Brochure CLARK CRX10 25FL EN

8 Pages

-

Specification sheet SRX14/16

6 Pages

-

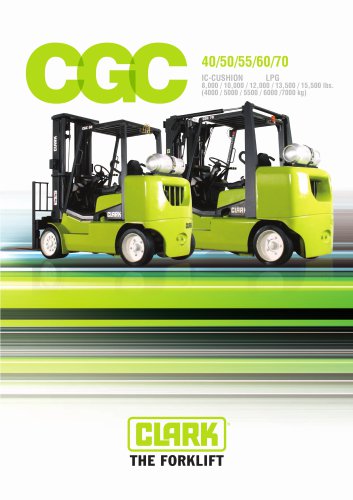

Specification sheet CGC40-70

6 Pages

-

Specification sheet S20-32C

6 Pages

-

Specification sheet C15-20sC

6 Pages

-

Specification sheet GTS20-33

6 Pages

-

Reach truck SRX14/16

8 Pages

-

Electric stacker SX12/16

8 Pages

-

CLARK Full Line

8 Pages

-

SX 12/16

6 Pages

Archived catalogs

-

Specification sheet WPio12

6 Pages

-

WSXD20

8 Pages

-

Brochure CLARK S-Series

8 Pages

-

WPX18

8 Pages

-

WP15

8 Pages

-

WPio12

2 Pages

-

C 15/18/20s(C) GEN2 Series

8 Pages

-

EPX 16/18/20s

5 Pages

-

TMX 13/15s/15/18/20x

7 Pages

-

GEX 40/45/50

8 Pages

-

GEX/GTX 16/18/20s

8 Pages

-

C40-55s

8 Pages

-

GTS20-33

8 Pages

-

WS 10M

8 Pages

-

WS 10

8 Pages

-

WSX 12/14

8 Pages

-

WSXD 20

8 Pages

-

CRT 16/20SE ac

8 Pages

-

CRT 14/16/20 ac

8 Pages

-

SRX 14/16

8 Pages

-

CRT 13/16K ac

8 Pages

-

WS & SX

8 Pages

-

WP & PX

8 Pages

-

PX20

8 Pages

-

C 60/70/75/80 GEN2 Series

8 Pages

-

C 40/45/50/55s Gen2 Series

8 Pages

-

CRX Series

6 Pages

-

CQ 20/25/30

6 Pages

-

CLARK Evolution

2 Pages

-

CTX 40/70

8 Pages

-

GEX 20/25/30(s/L)

8 Pages

-

Electric Reach Truck

8 Pages

-

Electric Power Stacker

8 Pages

-

Electric Pallet Truck

8 Pages

-

CGC 40/70 NON EU

10 Pages

-

C 15C/18C/20Cs GEN2 Series

8 Pages

-

GenEX Series GEX 40/45/50

8 Pages

-

CLARK_FULL-LINE

8 Pages

-

Data sheet CLARK-C40-55s

6 Pages

-

CLARK C60-80

8 Pages

-

Clark C 20-35

16 Pages

-

Clark CMP 50-75

2 Pages

-

Clark CMP 40-50s

2 Pages

-

CLARK CMP15-20

2 Pages

-

CLARK-GTX/GEX16-20s

12 Pages

-

CLARK CQ 20-30

6 Pages

-

Brochure CRX

6 Pages

-

Data sheet CLARK-CMP40-50s

6 Pages

-

Data sheet Clark-CMP50-75s

6 Pages

-

New GEX 20-30

10 Pages

-

Data sheet CLARK-GEN2 C20-35

7 Pages