Catalog excerpts

Working fluid From a primary pressure of +0.1MPa to twice the primary pressure (max. 0.99MPa) Proof pressure Body port thread B ressure P gauge option Flow rate m3 /min(ANR) Refer to the flow characteristics in the graph on the right Boosting ratio Ambient temp Port size Weightkg Durability A Body port thread: Rc thread C Silencer option: Silencer (2 pcs. included) D Bracket option: None Rc thread NPT thread (made to order) G thread (made to order) No Pressure gauge (2 included) No Silencer (2 pcs. included) High performance silencer (2 pcs. included) Functions Internal air circuit diagram No Foot bracket (2 included) Base for mounting tank Pressure adjustment section Switching valve Booster chamber B IN side check valve P rimary pressure from IN passes through the check valve on IN side, and flows into booster chambers A and B.The primary pressure passes through the pressure adjustment section and switching valve, and flows into the driving chamber A. The piston moves to the left due to the pressure of the driving chamber A. Air in booster chamber A is compressed, passes through the check valve on the OUT side, and goes to the OUT side. W hen the piston reaches the stroke end, the changeover switch will be pushed, causing compressed air to be supplied to the switching valve pilot chamber and causing the switching valve to change over. Then the air in drive chamber A is exhausted, and the air is delivered to drive chamber B. T herefore, the piston moves to the right and air in booster chamber B is compressed, passes through the check valve at the OUT side and moves OUT. I f the above operations are repeated, pressure will be increased on the OUT side. Feedback pressure is transmitted to the pressure adjustment section due to the OUT side pressure, and boosting is continued until the pressure adjustment spring pressure is balanced. Silencer option Silencer option B Pressure gauge option: Pressure gauge (2 included) Bracket option Pressure gauge option 10 million cycles (nominal) (Refer to page 2) Selection switch Piston Body port thread Piston OUTside check valve Fixed orifice OUTside (Secondary pressure)

Open the catalog to page 1

Flow characteristics (with the 5 L air tank, equivalent to double the pressure increase) Pressure characteristics (Setting: primary pressure: 0.7MPa, secondary pressure: 1.0MPa, flow rate: 0.02m3/min (ANR)) Fluid characteristics show max. flow rate of air booster. If primary pressure is constant and secondary side flow rate is increased, max. secondary pressure decreases. Pressure characteristics show variation of set secondary pressure according to primary pressure variation. Note) Air booster needs approx. twice secondary side flow rate (max.) for primary side due to structure. Confirm...

Open the catalog to page 2

ABP2-HP1 Series Internal structure

Open the catalog to page 3

ABP2-HP1 Series Parts list Parts list Part No. Part name Part No. Part name Hexagon socket head cap screw Stainless steel Valve seat Aluminum alloy Spring washer Stainless steel Nitrile rubber Flat washer Stainless steel Cylinder body Aluminum alloy Stainless steel Aluminum alloy Nitrile rubber Side plate Aluminum alloy Nitrile rubber Nitrile rubber Detection valve body Aluminum alloy Nitrile rubber Wear ring Nitrile rubber Aluminum alloy Fixed orifice Stainless steel Hexagon socket set screw Stainless steel Stainless steel Stainless steel Hexagon socket set screw Stainless steel Oiles...

Open the catalog to page 4

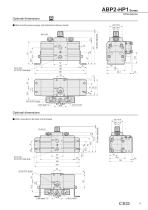

When mounting pressure gauge/silencer/bracket

Open the catalog to page 5

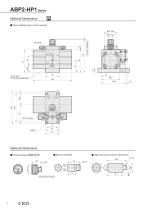

When mounting pressure gauge, high performance silencer, bracket Optional dimensions When mounted on the back of the bracket

Open the catalog to page 6

ABP2-HP1 Series Optional dimensions When installing base for tank mounting ø20, 49.6 High performance silencer (SLW-8A-H)

Open the catalog to page 7All CKD catalogs and technical brochures

-

【NEW】ABP2-HP1・AT2 Series Catalog

16 Pages

-

FP Series Precautions

7 Pages

-

FP Series Introduction

10 Pages

-

FCM Series Variation list

1 Pages

-

【NEW】WFK2 Series Catalog

24 Pages

-

【NEW】WFK2 Series Precautions

6 Pages

-

MN4GA / 4GB

140 Pages

-

4GD1 to 3R, 4GE1 to 3R

261 Pages

-

MV3QR

16 Pages

-

4F ** 0EX series

28 Pages

-

Pilot operated 5-port valve

74 Pages

-

MV3QRA1/MV3QRB1 Series

20 Pages

-

PV5G/PV5/GMF/PV5S-0

76 Pages

-

4G unit valve

4 Pages

-

SCP*3 Series

60 Pages

-

SCS2 series

56 Pages

-

Rodless cylinder SRL3

89 Pages

-

Linear slide cylinder LCG

58 Pages

-

Linear slide cylinder LCM

52 Pages

-

Linear slide cylinder LCX

64 Pages

-

Guided cylinder STM

24 Pages

-

Cartridge cylinder CAT

6 Pages

-

Compact cylinder SSD

221 Pages

-

Compact cylinder SSD2

278 Pages

-

Guided compact cylinder SSG

16 Pages

-

Medium bore size cylinder SCS

46 Pages

-

Medium bore size cylinder SCA2

161 Pages

-

Tie rod cylinder SCG

87 Pages

-

Medium bore size cylinder CMK2

107 Pages

-

Round shaped cylinder SCM

116 Pages

-

Medium bore size cylinder CMA2

20 Pages

-

Pencil shaped cylinder SCP*3

60 Pages

-

LMD series

15 Pages

-

KBZ series

64 Pages

-

AGD21R-A series

4 Pages

-

WXU series

32 Pages

-

AX6000M

24 Pages

-

SCS-G Series

2 Pages

-

CMK2 SR

7 Pages

-

CMK2 Series Double acting

7 Pages

-

SSD-F/SSD-KF Series

1 Pages

-

CMK2-T Series

1 Pages

-

SCPS2-V Series

4 Pages

-

SCPD2-*C Series

1 Pages

-

SCPD2-K Series

3 Pages

-

SCPS2-MSeries

4 Pages

-

SCPD2-D/SCPD2-DT Series

3 Pages

-

SCPD2-F Series

2 Pages

-

SCPD2 Serie

3 Pages

-

SCPD2 Series

2 Pages

-

SCPS Series

1 Pages

-

SCM Series ø 20 to ø 63

2 Pages

-

SCM Series

2 Pages

-

GHV series

4 Pages

-

High purity gas systems

2 Pages

-

Component for chemicals

2 Pages

-

Labor-Saving products

8 Pages

-

General purpose valve

1 Pages

-

Pneumatic valves

8 Pages

-

Pneumatic cylinders

12 Pages