Catalog excerpts

Compact/highly accurate actuator Highly compact, accurate, and rigid LCM Series linear slide. Actual size Ideal for high-accuracy positioning Ultimate pursuit of downsizing Highly accurate 0.005 mm sliding parallelism and The cylinder, linear guide, and slide table have been 0.03 mm installation parallelism are ensured, integrated into a highly compact unit. making this actuator ideal for positioning. Sliding parallelism Installation parallelism Linear Slide Cylinder Linear Slide Cylinder 1762

Open the catalog to page 1

Compatible with small spaces This cylinder can be installed even in compact spacing, making layout more flexible. 2 color switch mountable The 2 color indicator type has been added for mounting onto the F-type miniature switch. Switch rail Workpiece installation on either of two faces The workpiece can be directly installed either on the table top or front using the installation holes provided. Highly reliable stainless steel parts Corrosion-resistant stainless steel is used for the cylinder and slide table. Wide variation Available variations include adjustable stroke, side installation,...

Open the catalog to page 2

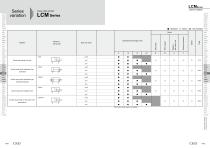

Series variation Series variation Linear slide cylinder Magnet + with switch rail Double acting single rod type Standard stroke length (mm) Bore size (mm) With magnet With buffer 8 LCM-P Double acting stroke adjustable type 8 LCM-R Double acting stroke adjustable type Double acting side installation type 8 LCM-P73 Double acting single rod type clean room specifications Linear slide cylinder Combined functions Note: Custom stroke length is not available.

Open the catalog to page 3

Pneumatic components Safety precautions Always read this section before starting use. Refer to Intro 67 for general precautions. Linear slide cylinder LCM Series Design & Selection Use the cylinder with the tolerable absorption or less shown below. If dynamic energy exceeds this value, consider using a separate shock absorber. CAUTION Refer to the LCM Selection Guide on pages 1816 to 1817 when selecting the cylinder. W hen using the cylinder where it could be subject to water or oil exposure, where it could corrode, or where high levels of dust are present, the cylinder could be damaged or...

Open the catalog to page 4

LCMSeries Precautions Installation & Adjustment When installing a jig guide, slide table, or end plate, observe the following values for bolt screw depth and tightening torque. Cylinder installation (side installation) Do not use the washer, etc. The installation bolt could contact the guide and break. Applicable bolts Cylinder installation This cylinder switch can be changed to one with a switch and the switch installation face can be changed. The tightening torque of the bolt fixing the switch rail is given below. The switch installation face port is not used, so attach a plug before...

Open the catalog to page 5

LCMSeries Installation & Adjustment 2. Side installation type 3. With buffer C are must be taken as the product can not be installed vertically if of the type with a buffer. CAUTION Interval larger than dimensions listed on the table below must be maintained if the side installation type is installed in parallel. A During Use & Maintenance CAUTION Apply CGL grease (Nippon Thompson) to the track rail's tracks of the guide after six months of use or 3,000,000 operations, whichever is sooner.

Open the catalog to page 6

Linear slide cylinder Double acting single rod type LCM Series Bore size: Specifications Descriptions Bore size Actuation Working fluid Max. working pressure Min. working pressure Withstanding pressure Ambient temperature Port size Stroke tolerance 6 Double acting Compressed air 0.7 0.2 Working piston speed Cushion Lubrication Allowable energy absorption None Rubber cushioned Not required (when lubricating, use turbine oil Class 1 ISOVG 32) Refer to the table on Page 1766. Specifications with buffer Descriptions Buffer stroke When set Buffer section spring load Operation Stroke length Bore...

Open the catalog to page 7

LCMSeries Specifications Switch specifications Proximity 2 wire F2H/F2V F2YH/F2YV Descriptions Applications Output method Power voltage Load voltage Load current Programmable controller 10 to 30 VDC 24 VDC 10% 5 to 20 mA LED Red/green LED (ON lighting) (ON lighting) 1 mA or less Light Leakage current Proximity 3 wire F3H/F3V F3YH/F3YV Programmable controller, relay NPN output 10 to 28 VDC 30 VDC or less 100 mA or less 50 mA or less LED Red/green LED (ON lighting) (ON lighting) 10 A or less Note 1: he maximum load current 20mA is applied at 25 . The current will be lower than 20mA if ambient...

Open the catalog to page 8

LCMSeries How to order Without switch With switch Bore size Piping direction Right viewed from rod end Left viewed from rod end Axial lead wire F2H* Radial lead wire F2V* Lead wire 1 color indicator type 2 color indicator type *Lead wire length Blank 3 E E Switch quantity With buffer With magnet Caution for model no. selection Note 1: Selection not required when designating the switch type. Note 2: Available only for LCM-6-10-R-F2H-R-J2 Model: Linear slide cylinder, double acting A B C D E F Bore size: Stroke length: Piping direction: Switch model no.: Switch quantity: Option: 6 mm 10 mm...

Open the catalog to page 9

How to order switch Switch body + switch rail + magnet Only switch body Switch quantity Stroke length Only switch rail Only magnet Bore size Switch rail • Stroke length Linear slide cylinder Combined functions

Open the catalog to page 10

LCMSeries Internal structure and parts list LCM-6, 8 LCM-4.5 to 8 with magnet/switch rail 17 Floating bush A Bolt End plate O ring Rod cover Rod packing seal Cylinder body Slide table Piston Piston packing seal O ring Material Stainless steel Stainless steel Aluminum alloy Nitrile rubber Acetar resin Nitrile rubber Stainless steel Stainless steel Stainless steel Nitrile rubber Nitrile rubber Guard Stop plate Machine screw Floating bush B Cushion rubber Hexagon socket head cap bolt Switch rail Plate Hexagon socket head cap bolt Magnet Dowel pin Material Acetar resin Stainless steel Stainless...

Open the catalog to page 11

Series Internal structure and parts list Internal structure and parts list LCM-4.5 to 8 with buffer 1 End plate Floating bush A Floating bush B Spring holder Coil spring Aluminum alloy Stainless steel Stainless steel Copper alloy Stainless steel Linear slide cylinder Combined functions

Open the catalog to page 12All CKD catalogs and technical brochures

-

【NEW】ABP2-HP1・AT2 Series Catalog

16 Pages

-

FP Series Precautions

7 Pages

-

FP Series Introduction

10 Pages

-

FCM Series Variation list

1 Pages

-

【NEW】WFK2 Series Catalog

24 Pages

-

【NEW】WFK2 Series Precautions

6 Pages

-

MN4GA / 4GB

140 Pages

-

4GD1 to 3R, 4GE1 to 3R

261 Pages

-

MV3QR

16 Pages

-

4F ** 0EX series

28 Pages

-

Pilot operated 5-port valve

74 Pages

-

MV3QRA1/MV3QRB1 Series

20 Pages

-

PV5G/PV5/GMF/PV5S-0

76 Pages

-

4G unit valve

4 Pages

-

SCP*3 Series

60 Pages

-

SCS2 series

56 Pages

-

Rodless cylinder SRL3

89 Pages

-

Linear slide cylinder LCG

58 Pages

-

Linear slide cylinder LCX

64 Pages

-

Guided cylinder STM

24 Pages

-

Cartridge cylinder CAT

6 Pages

-

Compact cylinder SSD

221 Pages

-

Compact cylinder SSD2

278 Pages

-

Guided compact cylinder SSG

16 Pages

-

Medium bore size cylinder SCS

46 Pages

-

Medium bore size cylinder SCA2

161 Pages

-

Tie rod cylinder SCG

87 Pages

-

Medium bore size cylinder CMK2

107 Pages

-

Round shaped cylinder SCM

116 Pages

-

Medium bore size cylinder CMA2

20 Pages

-

Pencil shaped cylinder SCP*3

60 Pages

-

LMD series

15 Pages

-

KBZ series

64 Pages

-

AGD21R-A series

4 Pages

-

WXU series

32 Pages

-

AX6000M

24 Pages

-

SCS-G Series

2 Pages

-

CMK2 SR

7 Pages

-

CMK2 Series Double acting

7 Pages

-

SSD-F/SSD-KF Series

1 Pages

-

CMK2-T Series

1 Pages

-

SCPS2-V Series

4 Pages

-

SCPD2-*C Series

1 Pages

-

SCPD2-K Series

3 Pages

-

SCPS2-MSeries

4 Pages

-

SCPD2-D/SCPD2-DT Series

3 Pages

-

SCPD2-F Series

2 Pages

-

SCPD2 Serie

3 Pages

-

SCPD2 Series

2 Pages

-

SCPS Series

1 Pages

-

SCM Series ø 20 to ø 63

2 Pages

-

SCM Series

2 Pages

-

GHV series

4 Pages

-

High purity gas systems

2 Pages

-

Component for chemicals

2 Pages

-

Labor-Saving products

8 Pages

-

General purpose valve

1 Pages

-

Pneumatic valves

8 Pages

-

Pneumatic cylinders

12 Pages